NiO/CdSe/MoS2 laminar composite photocathode and preparation method thereof

A photocathode, composite technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., to achieve the effect of facilitating electron transmission, shortening distance, and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. The preparation method of the new photocathode CdSe / NiO electrode is specifically prepared according to the following steps:

[0031] (1) Surface pretreatment of ITO conductive glass:

[0032] Soak the pretreated ITO conductive glass in absolute ethanol and acetone for two hours, and then heat and reflux in 2mol / L potassium hydroxide solution of isopropanol for 15 minutes.

[0033] (2) Preparation of NiO thin film by hydrothermal method

[0034] Put the ITO glass into 0.25mol / L Ni(NO 3 ) 2 ·6H 2 In a mixed aqueous solution of O and 0.25mol / L hexamethylenetetramine, heat at 100°C for 12min, take it out, wash it with deionized water five times, dry it in the air, and place it in a muffle furnace for calcination at 300°C for 30min to obtain NiO / ITO electrode.

[0035] (3) Preparation of cadmium selenide (CdSe) sensitized NiO composite electrode by ion alternating adsorption method

[0036] Immerse the ITO / NiO electrodes sequentially in 0.03mol / LCd 2+ and 0.03mol...

Embodiment 2

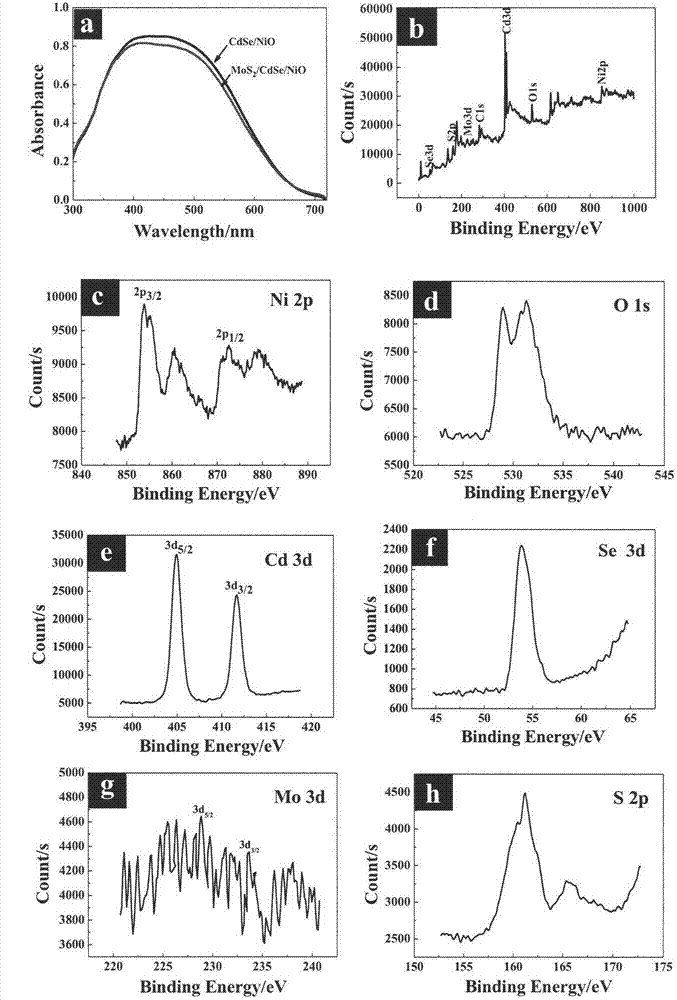

[0042] 1. Using MoS 2 As a co-catalyst supported on the surface of CdSe / NiO electrode, a more efficient photocathode MoS is prepared 2 / CdSe / NiO, specifically prepared according to the following steps:

[0043] (1) Surface pretreatment of ITO conductive glass:

[0044] Soak the pretreated ITO conductive glass in absolute ethanol and acetone for two hours, and then heat and reflux in 2mol / L potassium hydroxide solution of isopropanol for 15 minutes.

[0045] (2) Preparation of NiO thin film by hydrothermal method

[0046] Put the ITO glass into 0.25mol / L Ni(NO 3 ) 2 ·6H 2 In a mixed aqueous solution of O and 0.25mol / L hexamethylenetetramine, heat at 100°C for 12min, take it out, wash it with deionized water five times, dry it in the air, and place it in a muffle furnace for calcination at 300°C for 30min to obtain NiO / ITO electrode.

[0047] (3) Preparation of cadmium selenide (CdSe) sensitized NiO composite electrode by ion alternating adsorption method

[0048] Immer...

Embodiment 3

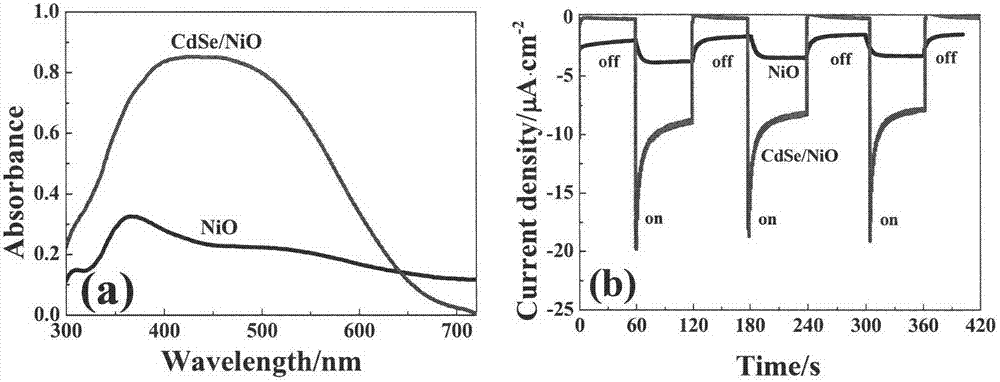

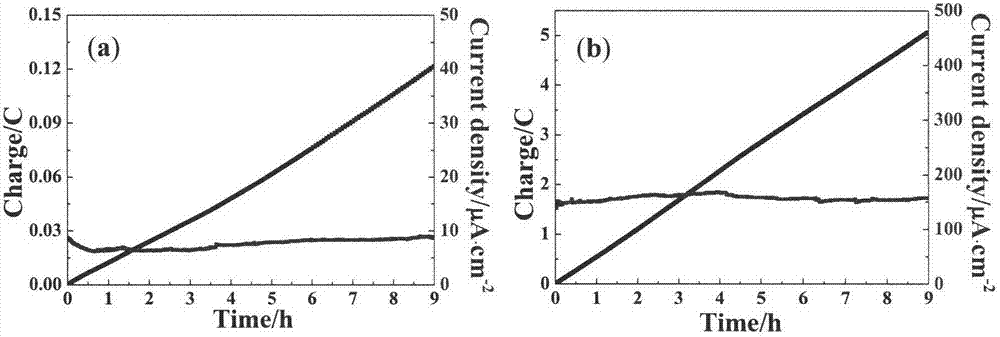

[0056] Layered Composite Photocathode NiO / CdSe and NiO / CdSe / MoS 2 Comparison of photoelectric hydrogen production performance under different conditions and the proposed photocatalytic hydrogen production mechanism.

[0057] A mixed aqueous solution (pH=6) of 0.30mol / L hexamethylenetetramine, 0.10mol / L hydrochloric acid and 0.20mol / L potassium chloride was used as the electrolyte solution, a 300W xenon lamp was used as the simulated light source, and Ag / AgCl electrodes were used as Reference electrode, platinum mesh as counter electrode, as-prepared CdSe / NiO and MoS 2 The / CdSe / NiO electrode was used as the working electrode, and the photoelectric hydrogen production experiment was done on the CHI600D electrochemical instrument. The amount of photocatalytic hydrogen production was detected by gas chromatography with a thermal conductivity detector. The composite photocathode CdSe / NiO and MoS of the present invention 2 / CdSe / NiO photoelectric hydrogen production performance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com