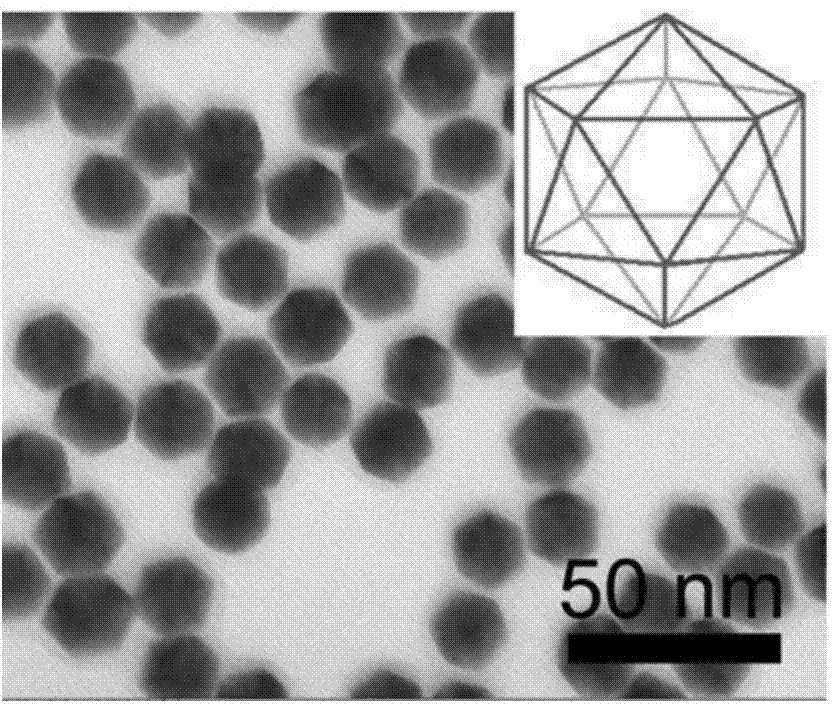

Au75Pd25 icosahedron nanocrystal with twin boundaries as well as preparation method and application of Au75Pd25 icosahedron nanocrystal

A technology of nanocrystals and icosahedrons, applied in the field of Au75Pd25/C bimetallic nanocatalysts, can solve problems such as synthesis difficulties, achieve broad application prospects, improve performance, and achieve uniform scale effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

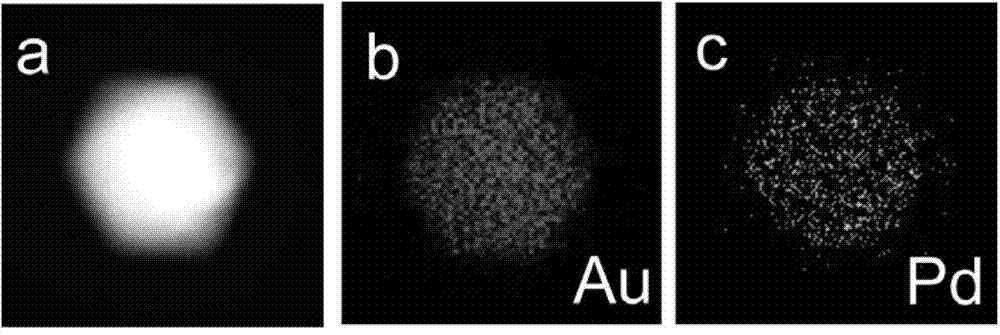

[0023] In this example, Au with twin grain boundary is prepared according to the following steps 75 PD 25 Icosahedral nanocrystals:

[0024] At room temperature, 0.75mL of 20mmol / L HAuCl 4 Aqueous solution, 2.5mL palladium acetylacetonate aqueous solution with a concentration of 2mmol / L, 150mg polyvinylpyrrolidone, 0.05mL potassium iodide aqueous solution with a concentration of 10mmol / L and 10mL N,N-dimethylformamide were added to a 20mL glass bottle, and then Put it in an ultrasonic instrument and sonicate for 2 minutes to mix the raw materials evenly, and place the obtained 20mL glass bottle containing the homogeneous mixture in an oil bath, and react at 140°C for 4h;

[0025] After the reaction of the homogeneous mixture is finished, it is cooled to room temperature, and centrifuged at 52,000 rpm for 15 minutes in an ultracentrifuge, and the centrifuged product is washed 4 times with ethanol solvent to wash away the polyethylene attached to the surface of the nanocrystal...

Embodiment 2

[0029] Preparation of Au for Catalytic Oxidation of Cyclohexane 75 PD 25 / C bimetallic nanocatalyst:

[0030] The Au prepared by embodiment 1 75 PD 25 2 mg of icosahedral nanocrystals was dissolved in 2 mL of ethanol to obtain a nanocrystal solution with a concentration of 1 mg / mL. In order to make the final product Au 75 PD 25 The mass fraction is 1.0%. Take 340 μL of this solution and inject it into 100 mL of carbon black ethanol solution with a concentration of 0.34 mg / mL. After ultrasonication for 3 hours and stirring for 12 hours, centrifuge, wash with deionized water, and dry at 70°C for 2 hours. The product Au 75 PD 25 / C bimetallic nanocatalyst, resulting product Au 75 PD 25 Au in / C bimetallic nanocatalyst 75 PD 25 The mass fraction is 1.0%.

Embodiment 3

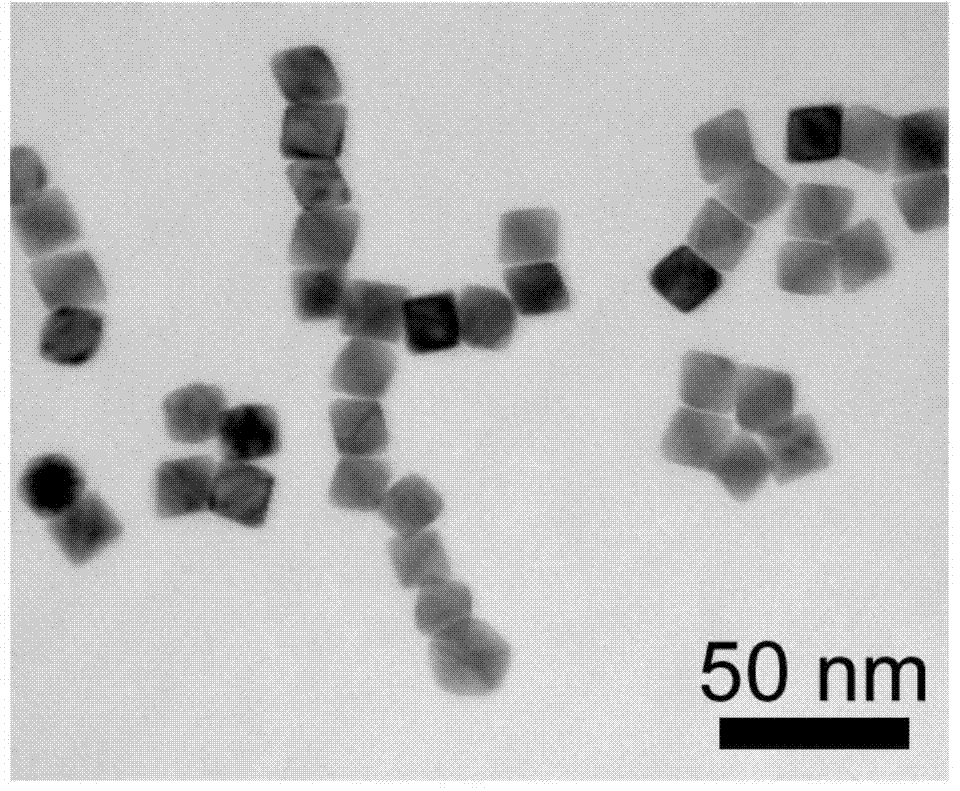

[0032] In order to compare the difference in catalytic performance, this example prepares Au without twin boundaries according to the following steps 75 PD 25 Octahedral nanocrystals and octahedral Au based on them 75 PD 25 / C Catalyst:

[0033] At room temperature, 0.75mL of 20mmol / L HAuCl 4 Aqueous solution, 2.5mL palladium acetylacetonate aqueous solution with a concentration of 2mmol / L, 150mg polyvinylpyrrolidone, 0.2mL potassium iodide aqueous solution with a concentration of 10mmol / L and 10mL N,N-dimethylformamide were added to a 20mL glass bottle, and then Place it in an ultrasonic instrument for 2 minutes and sonicate the raw materials to mix them evenly, and place the obtained 20mL glass bottle containing the homogeneous mixture in an oil bath, and react at 140°C for 4h;

[0034] After the reaction of the homogeneous mixture is finished, it is cooled to room temperature, and centrifuged at 52,000 rpm for 15 minutes in an ultracentrifuge, and the centrifuged produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com