Highly-conductive and high temperature resistant polymer

A high temperature resistant polymer, high conductivity technology, applied in the field of polymer and its preparation, can solve the problems of dust pollution, low dosage, difficult to evenly disperse, etc., to prevent electrostatic discharge, suppress electromagnetic interference, lubricate high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Mix 20 parts of commercially available tetrafluoroethylene and vinylidene fluoride with a weight-average molecular weight of 500,000 to 5 million, and 15 parts of pentaerythritol distearate with a high-speed mixer at a speed of 1000 rpm. The airtight mixing time is For 10 minutes, the temperature is controlled at 70°C, and then a single-screw or twin-screw extruder is used to obtain the required bonding material after drying;

[0020] (2) Mix the bonding material mixed in step 1 with 15 parts of resole phenolic resin IDP, 15 parts of PA46 and PA6T / 6I polyamide resin, and 5 parts of heat stabilizer CuI / KI (1:8), and add the Toluenesulfonic acid 20 parts; cured at room temperature for 7 days in an open polyethylene mold. Extrusion granulation at room temperature, vibrating sieve to produce high-conductivity and high-temperature-resistant polymers.

Embodiment 2

[0022] (1) Mix 25 parts of commercially available tetrafluoroethylene and vinylidene fluoride with a weight-average molecular weight of 500,000 to 5 million and 15 parts of pentaerythritol distearate with a high-speed mixer at a speed of 1000 rpm, and the airtight mixing time is For 15 minutes, the temperature is controlled at 75°C, and then a single-screw or twin-screw extruder is used to obtain the required bonding material after drying;

[0023] (2) Mix the bonding material mixed in step 1 with 10 parts of resole phenolic resin IDP, 15 parts of PA46 and PA6T / 6I polyamide resin, and 5 parts of heat stabilizer CuI / KI (1:8), and add the Toluenesulfonic acid 20 parts; cured at room temperature for 8 days in an open polyethylene mold. Extrusion granulation at room temperature, vibrating sieve to produce high-conductivity and high-temperature-resistant polymers.

[0024] The high-conductivity and high-temperature-resistant polymer described in the present invention is a white pr...

Embodiment 3

[0026] Example 3 Graphite was weighed into a plastic cup followed by the addition of solvated resole. The graphite and the solvated resole were premixed for 1 minute prior to the addition of the acid. After adding the acid, the pasty mixture was mixed for 30 seconds, then transferred to a 2 cm x 2 cm x 1 cm plastic mold and pressed manually. After 24 hours, the resistivity of the cured molded sample polymer was measured with the multimeter used in Example 1. The results obtained are shown in Table 1.

[0027] Example number Solvated Resole Resin acid weight Weight of Graphite (Based on Resole) acid weight Resistivity 1 10g 1g 0 10 20*10 4 2 10g 2g 0 40 10000 3 10g 4g 15g 100 1.5

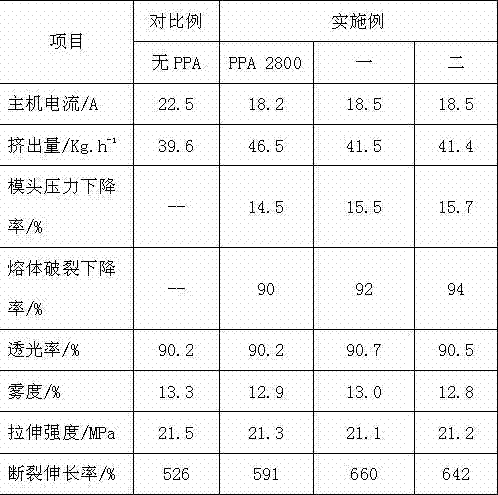

[0028] The high-conductivity and high-temperature-resistant polymers produced in Embodiment 1 and Embodiment 2 of the present invention are used to replace fluorine-containing polymers (PPA 2800) at an equivalent dosage of 800 ppm, and are applied...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com