Bacillus amyloliquefaciens and application thereof

A technology for dissolving amyloid spores and bacilli, applied in the directions of bacteria, hydrolase, enzymes, etc., can solve the reports that Bacillus amyloliquefaciens produce naringinase, the difficulty in cultivating high-yielding naringinase strains, the lack of large-scale naringinase, etc. problem, to achieve mild conditions, easy separation, and enhance the effect of flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

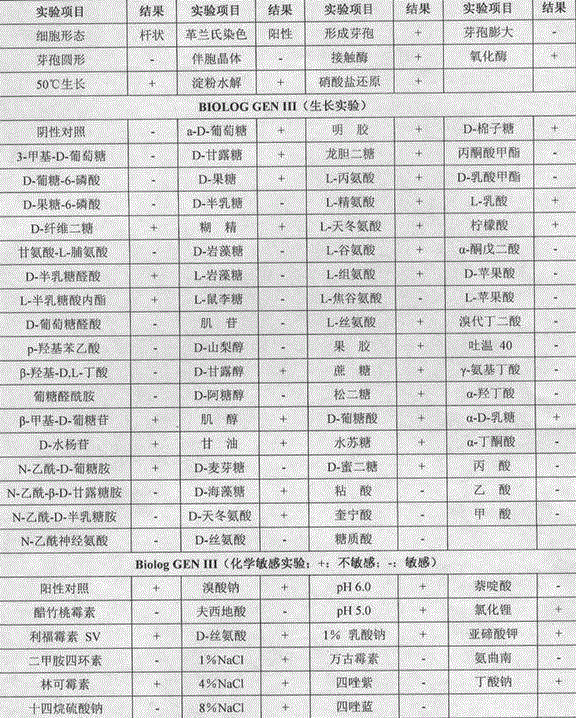

[0053] Example 1 Screening, isolation and identification of Bacillus amyloliquefaciens 11568

[0054] 1. Screening and isolation of Bacillus amyloliquefacines JNU002 (Bacillus amyloliquefacines) 11568

[0055] Weigh 2g of soil samples or moldy orange peel or / and pomelo peel collected from all over the country, and shake it in a 100mL conical flask filled with 18mL of sterilized normal saline for 30min. It is best to put a little glass beads in the conical flask . Then diluted with sterile water to a volume concentration of 1 × 10 -3 , 1×10 -4 For the two gradient dilutions, 100 μL of the dilutions were pipetted with a sterilized pipette tip and spread on the pre-prepared and sterilized selective plate medium, and incubated at 30°C for 48-96h. Separate the single colony by streaking from the selective plate medium, and check the purity of the strain by microscopic examination of part of the single colonies picked (microscopic observation of the bacteria shows the same...

Embodiment 2

[0075] Example 2 Preparation of liquid fermentation broth of Bacillus amyloliquefaciens 11568 containing naringinase

[0076] (1) Slant culture: Bacillus amyloliquefaciens 11568 was inoculated on the slant medium and cultured at 40°C for 48 hours to obtain the slant strain. The slant medium used (g / L) is: MgSO 4 0.5, KH 2 PO 4 1.5, CaCl 2 0.1, (NH 4 ) 2 SO 4 1.5, KCl 0.5, KNO3 1.5, yeast extract 2, orange peel powder 15, agar 20, pH 6.0, 1×10 5 Pa sterilized for 20 min.

[0077] (2) Liquid shake flask fermentation: Inoculate the obtained slant strain into the liquid shake flask culture medium with an inoculum amount of 0.2% (v / V), culture at 40.9°C, shaker speed 180r / min, and culture for 48 hours; the obtained liquid fermentation broth. Liquid shake flask medium (g / L) is: MgSO4 0.5, KH 2 PO 4 1.5, CaCl 2 0.1, (NH 4 ) 2 SO 4 1.5, KCl 0.5, KNO 3 1.5. Yeast paste 2. Orange peel powder 7.5, pH 6.0, 1×10 5 Pa sterilized for 20 min.

[0078] (3) Deter...

Embodiment 3

[0080] Example 3 Preparation of liquid fermentation broth of Bacillus amyloliquefaciens 11568 containing naringinase

[0081] Inoculate the slant strain cultivated in step (1) of Example 2 into a 250ml Erlenmeyer flask containing liquid medium at an inoculum size of 0.2% (v / V), and carry out liquid shake flask fermentation at a fermentation temperature of 40.9°C. The bed speed was 180 r / min, and the fermentation time was 48 h; a liquid fermentation liquid was obtained. Liquid medium composition (g / L): naringin 10, tryptone 10, (NH 4 ) 2 HPO 4 20, NaCl 10, yeast extract 5; pH 7.51, 1×10 5 Pa sterilized for 20 min.

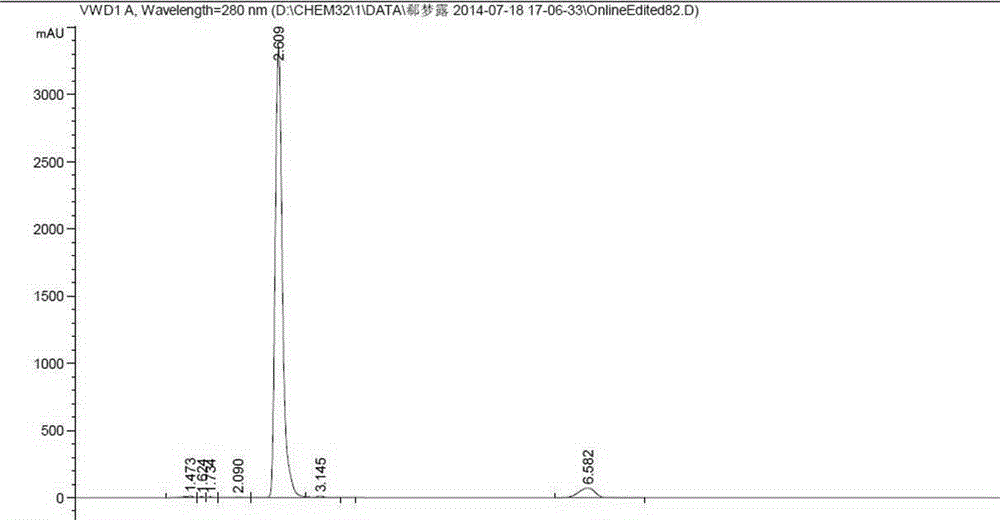

[0082] (3) Determine the composition of the liquid fermentation broth by high performance liquid chromatography (water: methanol = 1:1), and the test results are as follows: figure 1 : Contains naringin and naringenin in liquid fermented liquid.

[0083] (4) The naringinase activity of the liquid fermentation broth prepared in this example was measured acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com