After-treatment method for increasing flux of ultra-filtration membrane

A technology of ultrafiltration membrane and flux, applied in ultrafiltration, chemical instruments and methods, membrane technology, etc., can solve the problems of complicated process operation, increase of preparation cost, and difficulty of quality control of casting liquid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

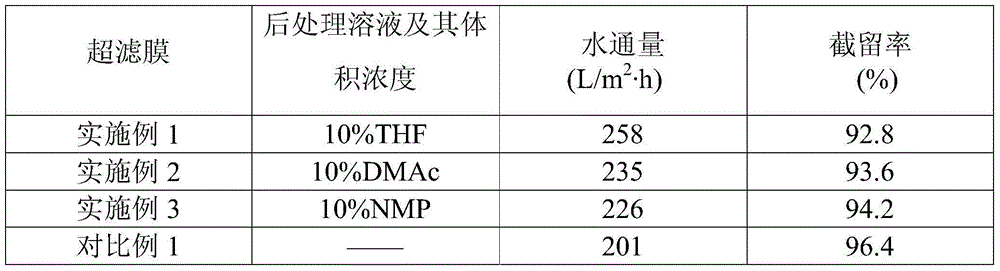

[0021] In this group of examples, the test performance of the ultrafiltration membrane prepared by post-treatment with different solutions is listed. The volume concentration of the post-treatment solution in the embodiment is 10%, and the preparation method is to measure the selected reagent and place it in a volumetric flask, and then add deionized water to the mark. Specifically, Example 1, Example 2, and Example 3 were prepared from tetrahydrofuran (THF), N,N-dimethylacetamide (DMAc), and N-ethylpyrrolidone (NMP) respectively, with a volume concentration of 10%. solution. The prepared solution was stored at room temperature (22°C).

[0022] Use a polysulfone ultrafiltration membrane with a PEG molecular weight cut-off of 100,000, contact with the prepared solution at room temperature for 60 seconds, rinse in water at 25°C for 10 minutes, and store in deionized water.

[0023] Test the flux of the post-treated ultrafiltration membrane with pure water under a pressure of 0...

Embodiment 4-6

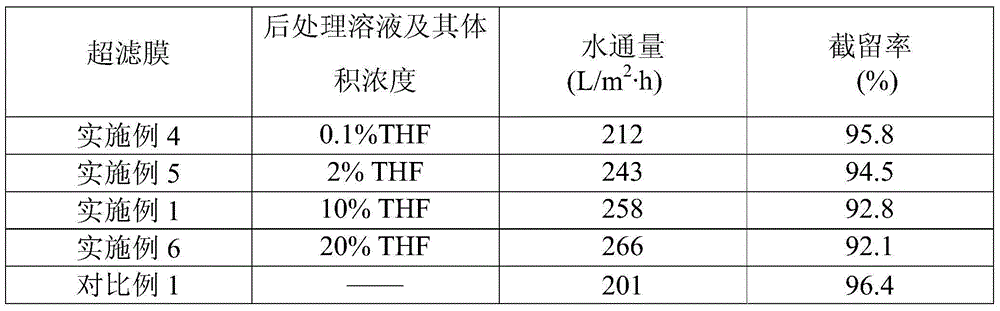

[0035] In this group of examples, the test performances of ultrafiltration membranes prepared by using post-treatment solutions with different THF concentrations are listed. In the examples, the selected experimental steps, methods, and experimental conditions are the same as those described in Examples 1-3.

[0036] The test results are shown in Table 2.

[0037] Table 2

[0038]

[0039] It can be seen from the data in Table 2 that no matter what the concentration of the infiltration solution is, the water flux of the ultrafiltration membrane soaked by the solution increases, and the greater the concentration of the infiltration solution, the greater the increase in the water flux; While the water flux increases, the interception rate remains basically unchanged.

Embodiment 7-9

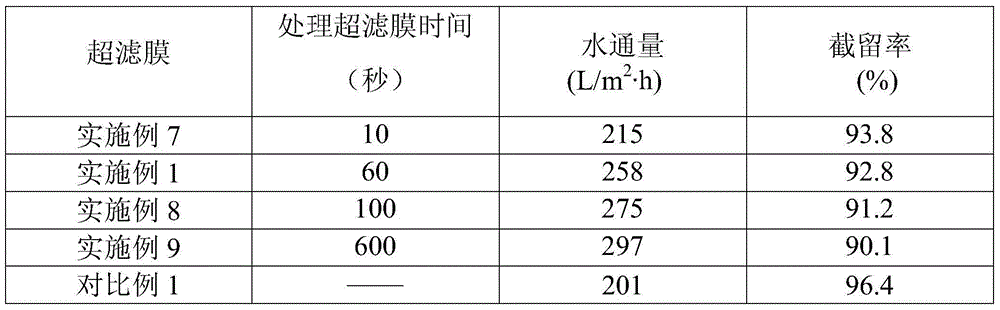

[0041] In this group of examples, the performance results of the post-treatment of ultrafiltration membranes at different times are listed. In this group of examples, 10% THF aqueous solution was used to treat the ultrafiltration membrane. The selected experimental steps, methods, and experimental conditions are the same as those described in Examples 1-3.

[0042] The test results are shown in Table 3

[0043] table 3

[0044]

[0045] It can be seen from the data in Table 3 that the longer the ultrafiltration membrane is immersed in the solution, the greater the increase in water flux.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pure water flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com