Preparation method of open-celled high-energy molecular microspheres

A technology of polymer microspheres and open-pore structure, applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of difficulty in controlling pore size and pore distribution, high toxicity of nitromethane, and high cost of nitromethane, and achieve easy control. , the effect of low toxicity and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

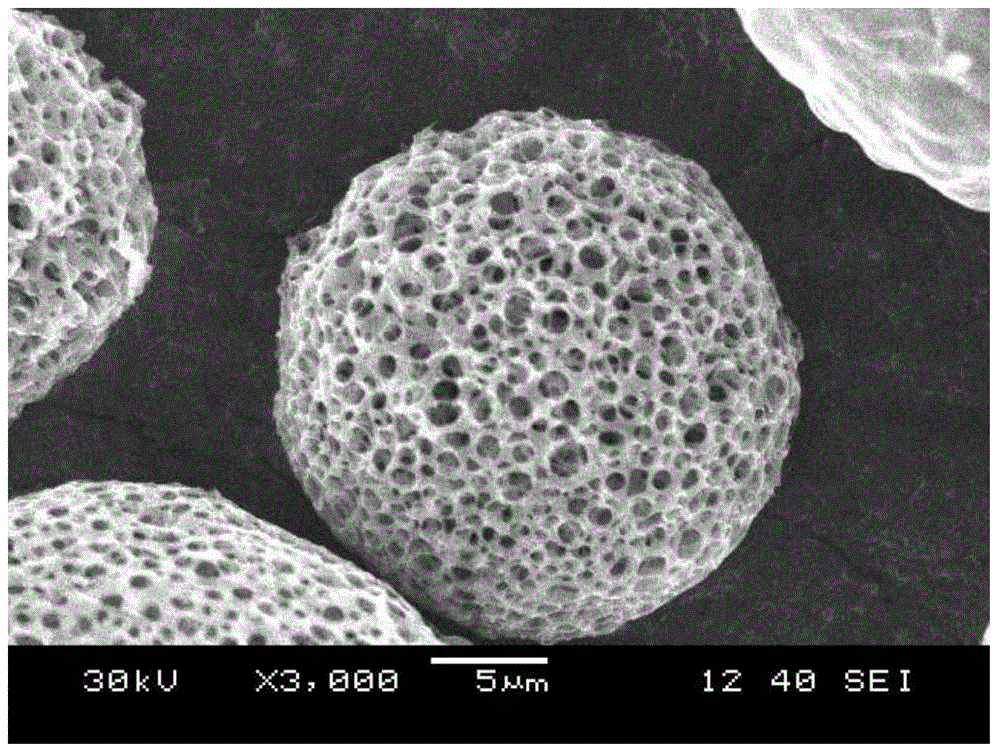

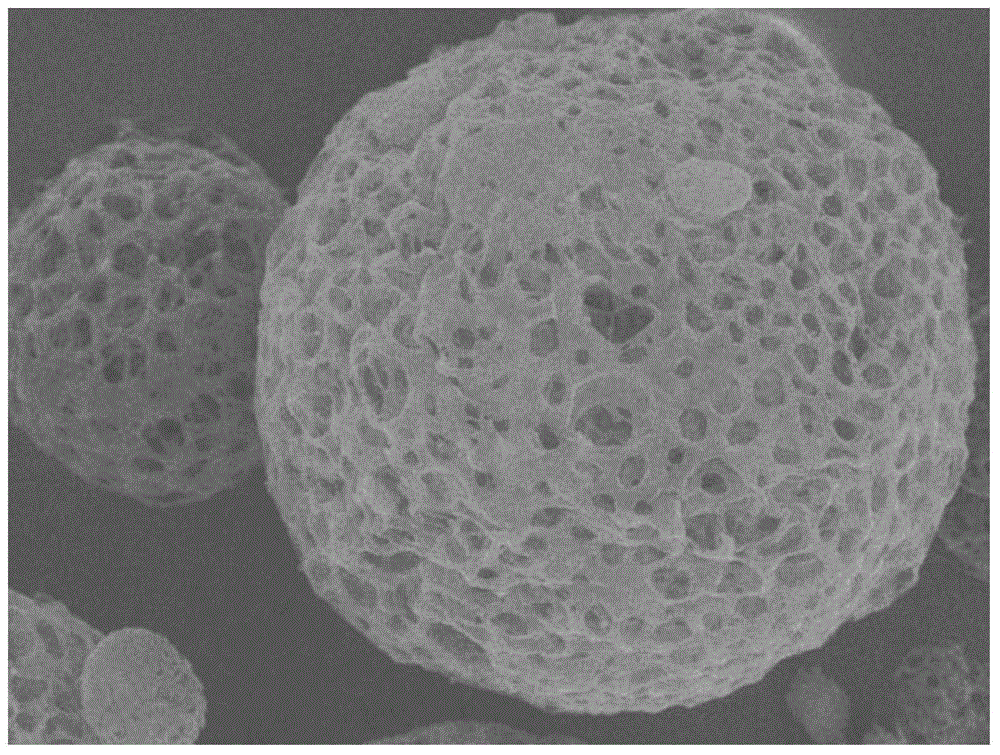

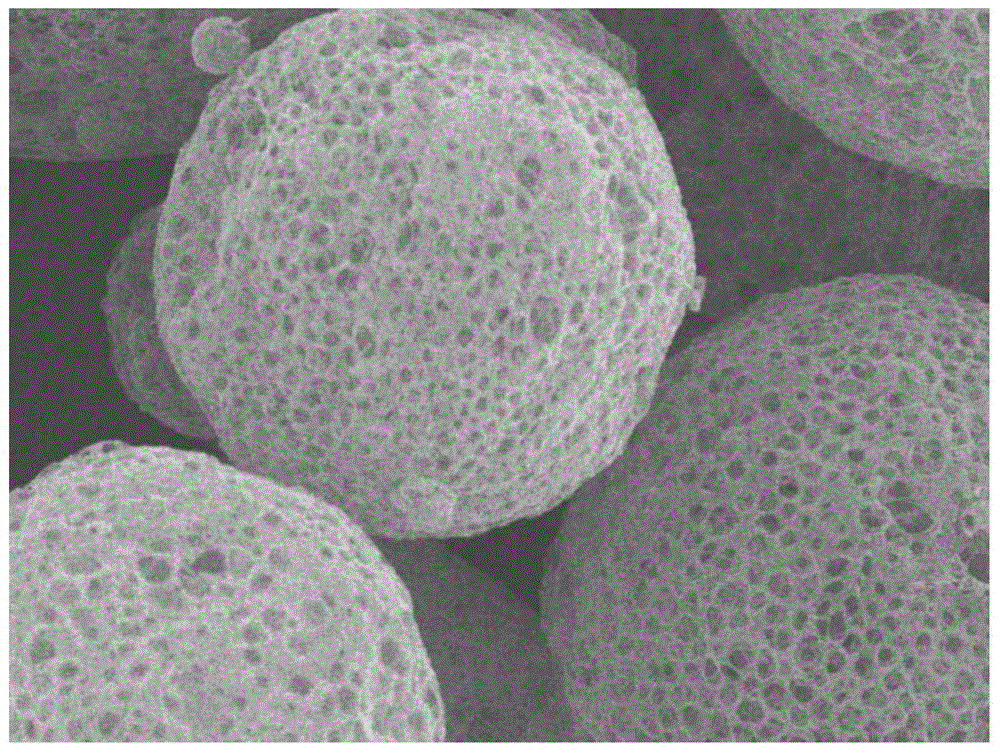

Image

Examples

preparation example Construction

[0024] A method for preparing energetic polymer microspheres with an open-pore structure includes the following steps:

[0025] Step 1. Dissolve the energy-containing polymer material containing nitrocellulose in ethyl acetate to obtain a polymer sol containing nitrocellulose; the energy-containing polymer material containing nitrocellulose is nitrification with a nitrogen content greater than or equal to 11.5% One of cotton, single-base medicine, double-base medicine or modified double-base medicine containing high-energy explosive. The amount of ethyl acetate is 4.0-100 times the mass of the energetic polymer material. The high-energy explosives are elemental explosives such as Roxykin or Oktokin.

[0026] Step 2. Under stirring conditions, gradually add an alkane solvent to the polymer sol described in step 1, and obtain a polymer sol containing a mixed solvent or a polymer emulsion with an alkane solvent as the inner phase after thorough mixing; The alkane solvent is one or a ...

Embodiment 1

[0042] A 2-liter three-necked flask was used as the pelletizing reactor, and nitrocellulose with a nitrogen content of 11.9% and a moisture content of 4% was used as the raw material. The nitrocellulose was added to the reactor, and 20 times the raw material was added under stirring. Dry) quality ethyl acetate solvent, that is, the solvent ratio is 20. After dissolving for 30 minutes, a polymer sol containing nitrocellulose is obtained. Then, 5 times the mass of the crude drug is added to the system, and the mixture is stirred and dispersed for 30 minutes at room temperature. Then continuously add an aqueous solution containing OP-10 non-ionic surfactant to the system. The surfactant concentration in the aqueous solution is 0.25%. The volume of the aqueous solution added is 0.25 times the volume of ethyl acetate in step 1. Continue after the aqueous solution is added Stir for 30 minutes to form a homogeneous polymer emulsion. Next, the polymer emulsion is dispersed in an aqueou...

Embodiment 2

[0044] A 2-liter three-necked flask was used as the pelletizing reactor, and nitrocellulose with a nitrogen content of 11.5% was used as the raw material. The nitrocellulose was added to the reactor, and 10 times the weight of the raw material (dry) was added under stirring. Ethyl acetate solvent, that is, the solvent ratio is 10, after 30 minutes of dissolution, a polymer sol containing nitrocellulose is obtained, and then 4 times the mass of the crude drug is added to the system, and the mixture is stirred and dispersed for 30 minutes at room temperature. Then continuously add an aqueous solution containing cationic surfactant cetyltrimethylammonium chloride to the system, the concentration of cetyltrimethylammonium chloride in the aqueous solution is 0.25%, and the volume of the aqueous solution added is the acetic acid in step 1. 0.4 times the volume of the ethyl ester. After adding the aqueous solution, continue to stir for 30 minutes to form a uniform polymer emulsion. Ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com