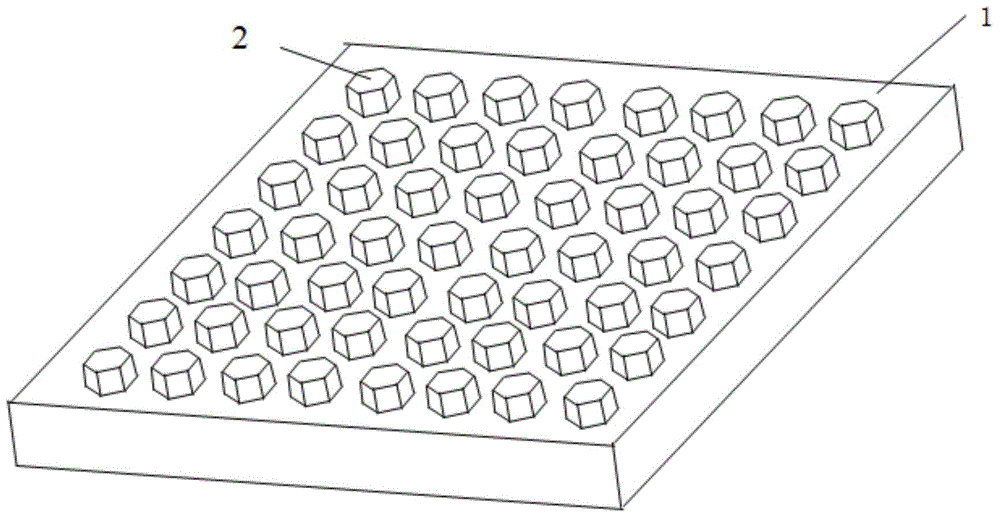

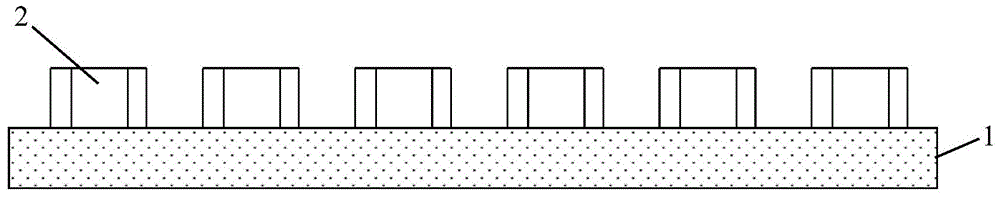

Surface enhanced Raman scattering sensor and preparation method thereof

A surface-enhanced Raman and sensor technology, which is applied in the directions of Raman scattering, material excitation analysis, etc., can solve the problem that it is difficult to obtain the SERS surface substrate with precise control of the degree of arraying, and achieve reduced production costs, simple preparation process, enhanced Effect of Raman scattering signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

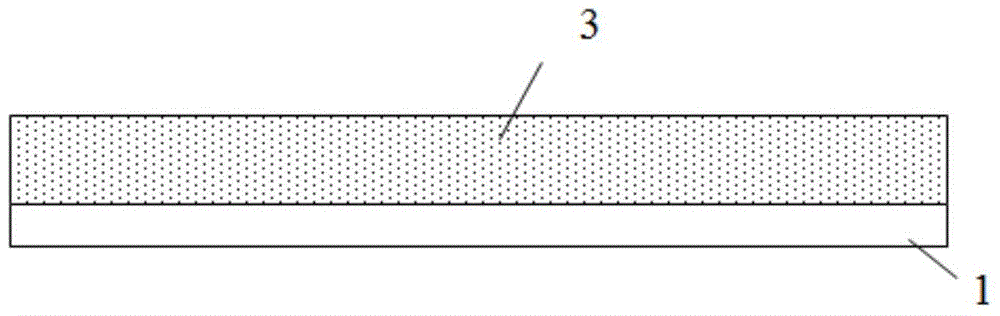

[0033] 4.89gAlCl 3 , 3.87gLiAlH 4 Dissolve in 30ml and 70ml of anisole respectively at -78°C under the protection of nitrogen. After the dissolution is complete, mix the two to form an aluminum hydride-anisole complex. Evaporate the solution to dryness and filter to obtain a white solid. The above solid was dissolved in 20ml of tetrahydrofuran solvent, and 1wt% surfactant was added at the same time to keep the ink stable for a long time. A conductive aluminum film layer with a thickness of 600 nm was printed on the ITO substrate by inkjet printing, and the active agent was ethylene glycol.

[0034] At a temperature of 60°C, with the ITO substrate printed with a conductive aluminum film layer as the anode and Pt as the cathode, the concentration of 15wt% H 2 SO 4 In the process, the anodic oxidation was carried out for 5h at a DC voltage of 40V. After the oxidation is completed, use 7% H 3 PO 4 and H at a mass concentration of 2% 2 CrO 4 Mix the solution to remove the a...

Embodiment 2

[0038] with AlH 3 {O(C 4 h 9 ) 2} solution as aluminum ink, with Ti(O-i-Pr) 4 As a catalyst, the catalyst was first coated on the substrate and preheated on a hot plate at 110°C for 60s, then the aluminum ink was printed on the substrate and reacted for 10 minutes to obtain a highly conductive aluminum layer with a thickness of 600nm. Among them, the preparation of aluminum ink is 1.33g of AlCl 3 , 1.11g of LiAlH 4 Dissolve in 50ml of butyl ether at -78°C under the protection of nitrogen. After the dissolution is complete, mix the two to form a complex of aluminum hydride-butyl ether. Evaporate the solution to dryness and filter to obtain a white solid. The above solid Dissolve in 20ml of tetrahydrofuran solvent, and add 1wt% surfactant at the same time to make aluminum ink; the substrate of this embodiment is glass.

[0039] At a temperature of 25°C, with a glass substrate printed with a conductive aluminum film layer as the anode and Pt as the cathode, in a concentrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com