Chitin-containing slow-release fertilizer and preparation method thereof

A slow-release fertilizer and chitin technology, applied in the direction of organic fertilizers, inorganic fertilizers, fertilizer mixtures, etc., can solve the problems of application and development limitations, improve physical and chemical properties and microbial flora, promote synergy, and enhance fertilizer efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

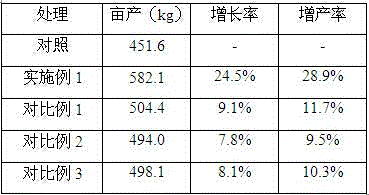

Examples

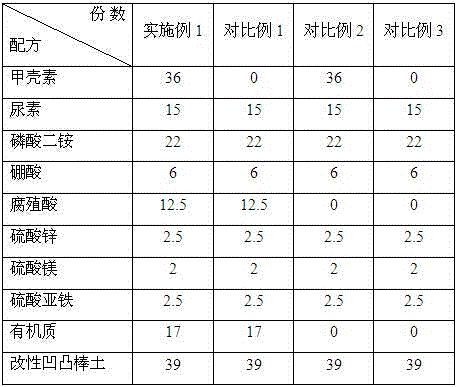

Embodiment 1

[0023] The chitin-containing slow-release fertilizer described in this embodiment contains the following components in parts by weight: 36 parts of chitin, 15 parts of urea, 22 parts of diammonium phosphate, 6 parts of boric acid, 12.5 parts of humic acid, zinc sulfate 2.5 parts, magnesium sulfate 2 parts, ferrous sulfate 2.5 parts, organic matter 17 parts, modified attapulgite 39 parts.

[0024] The concrete preparation method of described slow-release fertilizer comprises the steps:

[0025] S1. Take each raw material by weight parts of the raw materials, grind the urea, diammonium phosphate, boric acid, zinc sulfate, magnesium sulfate, ferrous sulfate, mix uniformly, and granulate, as the core particle of the compound fertilizer, the particle size About 3mm;

[0026] S2. Mix chitin, organic matter, and humic acid evenly, wrap and dry the core particles of the compound fertilizer obtained in S1, and the thickness of the wrapping is about 85g / m 2 ;

[0027] S3. Evenly adhe...

Embodiment 2

[0029] The chitin-containing slow-release fertilizer described in this embodiment contains the following components in parts by weight: 10 parts of chitin, 15 parts of ammonium nitrate, 15 parts of monoammonium phosphate, 6 parts of sodium octaborate tetrahydrate, humic acid 15.5 parts, 2.5 parts of zinc sulfate, 2 parts of magnesium sulfate, 2.5 parts of ferrous sulfate, 17 parts of organic matter, 39 parts of modified attapulgite.

[0030] The concrete preparation method of described slow-release fertilizer comprises the steps:

[0031] S1. Weigh each raw material according to the parts by weight of the raw materials, grind the ammonium nitrate, monoammonium phosphate, sodium octaborate tetrahydrate, zinc sulfate, magnesium sulfate, ferrous sulfate, mix uniformly, and granulate as a compound fertilizer Core particles, particle size 3.4mm;

[0032] S2. Mix chitin, organic matter, and humic acid evenly, wrap and dry the core particles of the compound fertilizer obtained in S1...

Embodiment 3

[0035] The chitin-containing slow-release fertilizer described in the present embodiment contains the following components in parts by weight: 45 parts of chitin, 15 parts of ammonium sulfate, 12 parts of monoammonium phosphate and diammonium phosphate, sodium octaborate tetrahydrate and borax 8 parts, humic acid 5 parts, zinc sulfate 1 part, magnesium sulfate 3 parts, ferrous sulfate 1 part, organic matter 12 parts, bentonite 30 parts.

[0036] The concrete preparation method of described slow-release fertilizer comprises the steps:

[0037] S1. Take each raw material by weight parts of the raw materials, grind the ammonium sulfate, monoammonium phosphate and diammonium phosphate, sodium octaborate tetrahydrate and borax, zinc sulfate, magnesium sulfate, ferrous sulfate, mix uniformly, Granulation, as the core granules of compound fertilizer, the particle size is about 2.8mm;

[0038] S2. Mix chitin, organic matter, and humic acid evenly, wrap and dry the core particles of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com