Preparation method of anti-fouling waterproof coating adopting modified acrylic acid

A waterproof coating, acrylic technology, applied in the field of coatings, can solve the problems of large surface roughness, difficult cleaning work, difficult to clean, etc., achieve good dispersion effect, simple method, and improved weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

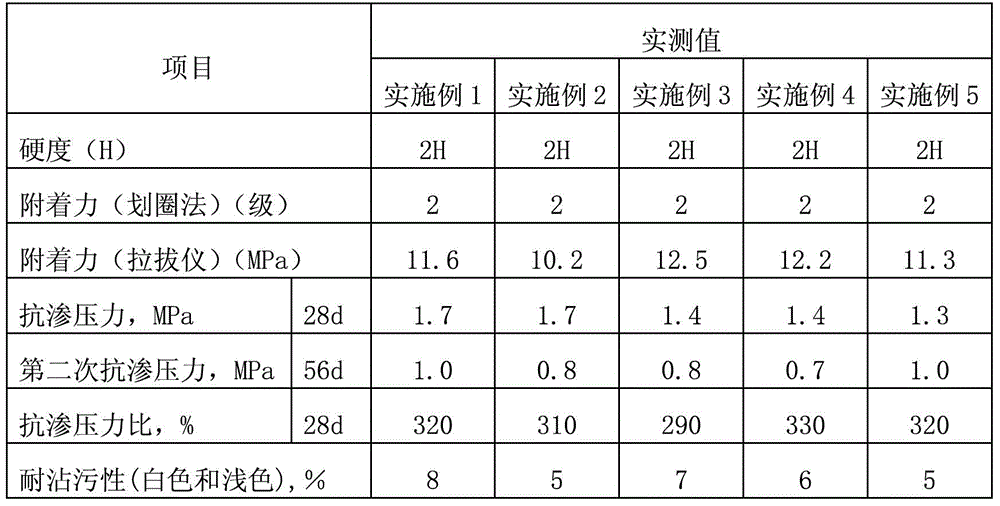

Examples

Embodiment 1

[0027] The concrete preparation steps of antifouling and waterproof coating in the present embodiment are:

[0028] 1) Preparation of modified acrylate

[0029] Put 55g of methyl acrylate in a dry reaction kettle, raise the temperature to 110-120°C, and treat it at a vacuum degree of -0.1Mpa for 0.5-1h until no bubbles are generated, then cool down to 75°C, and add 1.2g of alkylphenol polyoxygen Vinyl ether, 0.8g sodium lauryl sulfate, and 1.5g sodium bicarbonate, stirred, kept the temperature at 75-80°C for 0.5h, then added dropwise 23g trifluoroethyl acrylate and 15g mass fraction of 5% Sodium persulfate solution, both are continuously added dropwise, the dropwise addition time is 1.5~2h, after the dropwise addition, the stirring reaction is accelerated for 1h, then cooled to room temperature, and filtered with a 100-mesh sieve to obtain a modified acrylate emulsion;

[0030] 2) Preparation of modified emulsion with uniform dispersion of nano powder

[0031] a, 5g nano-sil...

Embodiment 2

[0037] The concrete preparation steps of antifouling and waterproof coating in the present embodiment are:

[0038] 1) Preparation of modified acrylate

[0039] Put 60g of 2-ethyl methacrylate in a dry reaction kettle, raise the temperature to 110-120°C, and treat it at a vacuum degree of -0.1Mpa for 0.5-1h until no bubbles are generated, then cool down to 75°C, and add 2g of alkylphenol Polyoxyethylene ether, 0.8g sodium lauryl sulfate, and 1g sodium bicarbonate, stirred, kept the temperature at 75-80°C for 0.5h, then added dropwise 15g trifluoroethyl methacrylate and 10g mass fraction at the same time 5% sodium persulfate solution, both of which are continuously added dropwise, the dropping time is 1.5~2h, after the dropwise addition, the stirring reaction is accelerated for 1h, then the temperature is lowered to room temperature, and the modified acrylate is obtained by filtering with a 100-mesh sieve Lotion;

[0040] 2) Preparation of modified emulsion with uniform dispe...

Embodiment 3

[0047] The concrete preparation steps of antifouling and waterproof coating in the present embodiment are:

[0048] 1) Preparation of modified acrylate

[0049] Put 50g of methyl methacrylate in a dry reaction kettle, raise the temperature to 110-120°C, and treat it at a vacuum degree of -0.1Mpa for 0.5-1h until no bubbles are generated, then cool down to 75°C, and add 0.8g of alkylphenol Polyoxyethylene ether, 1g sodium lauryl sulfate, and 1.7g sodium bicarbonate, stirred, kept the temperature at 75-80°C for 0.5h, then added dropwise 30g trifluoroethyl methacrylate and 12g mass fraction at the same time 5% sodium persulfate solution, both of which are continuously added dropwise, the dropping time is 1.5~2h, after the dropwise addition, the stirring reaction is accelerated for 1h, then the temperature is lowered to room temperature, and the modified acrylate is obtained by filtering with a 100-mesh sieve Lotion;

[0050] 2) Preparation of modified emulsion with uniform disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com