Preparation method of xylogen-based magnetic solid acid catalyst

A magnetic solid acid, lignin-based technology, applied in the direction of organic chemistry, can solve the problems of difficult separation and recycling of carbon-based solid acids, the inability to achieve large-scale production, complicated preparation procedures, etc., and achieve good catalytic effect and low production cost. The effect of low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

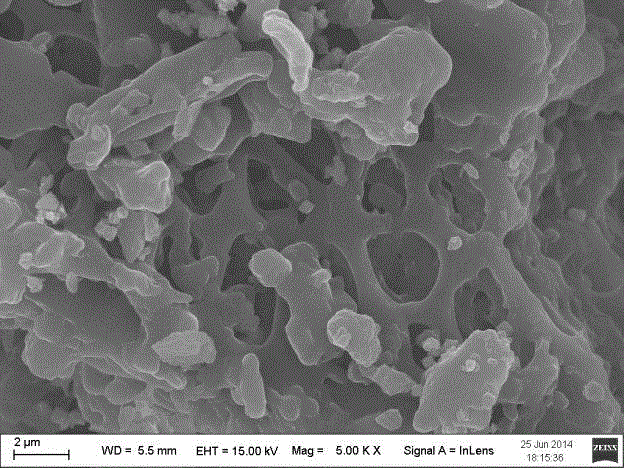

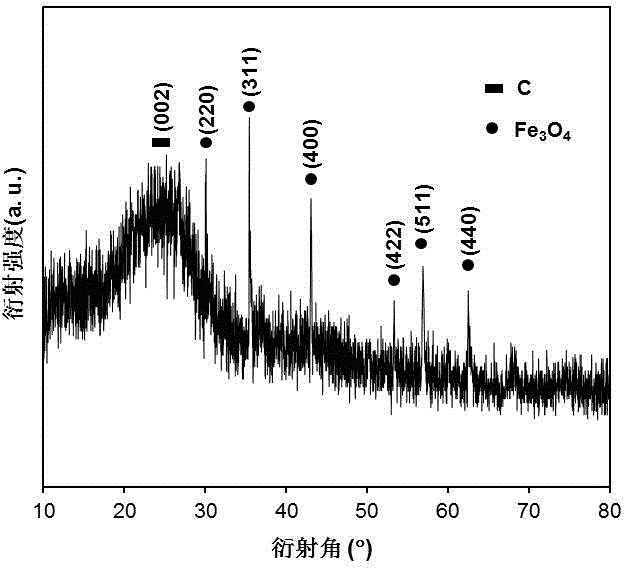

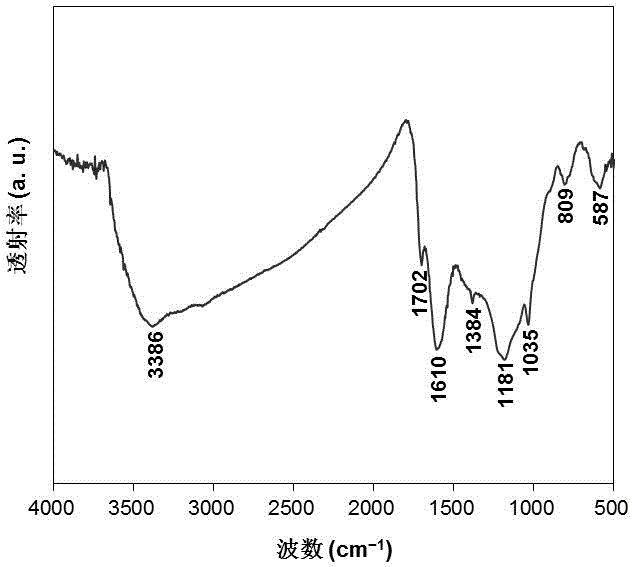

[0022] Example 1: Weigh 20 g of residual lignin from enzymatic hydrolysis of corncobs, wash 12 times with deionized water and absolute ethanol, and dry in vacuum at 105 °C for 8 h; grind the residual lignin from enzymatic hydrolysis after washing and drying to a size of 200 mesh , and it was added to a concentration of 20 mmol·L according to the solid-liquid ratio of 1:50 -1 Stir in the ferric chloride solution for 10 h, then heat to evaporate the excess water in the solution, and the remaining solid mixture is vacuum-dried at 105 °C for 8 h; impregnate the dried enzymatic residue lignin with ferric chloride and continue grinding To a size of 200 mesh, carbonize it at 600 °C under nitrogen atmosphere for 1 h; add the carbonized lignin-based magnetic carbon carrier to sulfallic acid at a solid-to-solid ratio of 1:10, and stir at 200 °C under nitrogen atmosphere Heated for 5 h; the sulfonated lignin-based magnetic carbon carrier was washed with deionized water at 100 °C until ...

Embodiment 2

[0023] Example 2: Weigh 10 g of residual lignin from enzymatic hydrolysis of corn stalks, wash with deionized water and absolute ethanol for 6 times, and dry in vacuum at 65 °C for 24 h; grind the lignin from enzymatic hydrolysis residue after washing and drying to 100 mesh size , and it was added to a concentration of 10 mmol·L according to the solid-liquid ratio of 1:100 ?1 Stir in the ferric chloride solution for 5 h, then heat to evaporate the excess water in the solution, and dry the remaining solid mixture in vacuum at 65 °C for 24 h; impregnate the dried enzymatic residue lignin with ferric chloride and continue grinding to a size of 100 mesh, carbonize it at 400 °C for 5 h under a nitrogen atmosphere; add the carbonized lignin-based magnetic carbon carrier to thioglycolic acid at a solid-to-liquid ratio of 1:20, and stir at room temperature for 24 h under a nitrogen atmosphere. After filtration, it was added to 30% hydrogen peroxide at a solid-to-liquid ratio of 1:20...

Embodiment 3

[0024] Example 3: Weigh 15 g of enzymolysis residue lignin, wash with deionized water and absolute ethanol 8 times respectively, and vacuum-dry at 80 °C for 12 h; grind the enzymolysis residue lignin after washing and drying to 400 mesh size, and It was added according to the solid-liquid ratio of 1:80 to a concentration of 25 mmol L ?1 Stir in the ferric chloride solution for 8 h, then heat to evaporate the excess water in the solution, and the remaining solid mixture is vacuum-dried at 80 °C for 12 h; impregnate the dried enzymatic residue lignin with ferric chloride and continue grinding To 400 mesh size, carbonize it at 500 °C for 3 h under nitrogen atmosphere; add the carbonized lignin-based magnetic carbon carrier to mercaptopropionic acid at a solid-to-liquid ratio of 1:15, and stir at room temperature for 12 h under nitrogen atmosphere , after filtration, it was added to concentrated nitric acid at a solid-to-liquid ratio of 1:15, and stirred at room temperature for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com