Mesoporous phenolic resin/copper nano particle heterogeneous catalyst, and preparation method and application of catalyst

A heterogeneous catalyst, phenolic resin technology, applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, chemical instruments and methods, etc., can solve the problem of inability to obtain satisfactory catalytic performance, particle size distribution Inhomogeneous, mesoporous structure damage and other problems, to achieve the effect of eliminating the diffusion of reaction substrates, easy to scale implementation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 orderly prepares the preparation of mesoporous phenolic resin

[0041] Weigh 6.0g of phenol into a 100ml three-necked flask, add 1.3g of sodium hydroxide with a mass fraction of 20%, raise the temperature to 40°C, stir for half an hour until dissolved, slowly add formaldehyde with a mass fraction of 37% 10.5g, heated to 70°C, stirred, and reacted for 2 hours. After cooling to room temperature, add 2 moles per liter of hydrochloric acid pre-configured dropwise to make the whole solution neutral, spin at 50°C for 2 hours, and then dilute 4 times with absolute ethanol to obtain oligomers. Then weigh 1.0g of polyethylene glycol-polypropylene glycol-polyethylene glycol triblock polymer (F127), 20g of absolute ethanol at 40°C, stir for 0.5h until dissolved, add 5.0g of oligomer dropwise, and stir for 1 hour , transferred to a petri dish, kept at room temperature for 8h, then raised to 100°C, kept for 24h, and a transparent film was obtained, namely phenolic resi...

Embodiment 2

[0042] Example 2 Preparation of Mesoporous Phenolic Resin Supported Copper Nanoparticle Heterogeneous Catalyst

[0043] After taking by weighing the powder of 1.0g embodiment 1 obtained film and mixing with 0.1g copper nitrate, transfer to ball mill, grind for a period of time, transfer to quartz boat then, N 2 In the atmosphere, the temperature was increased to 350°C at a rate of 2°C / min, and calcined for 6h.

Embodiment 3

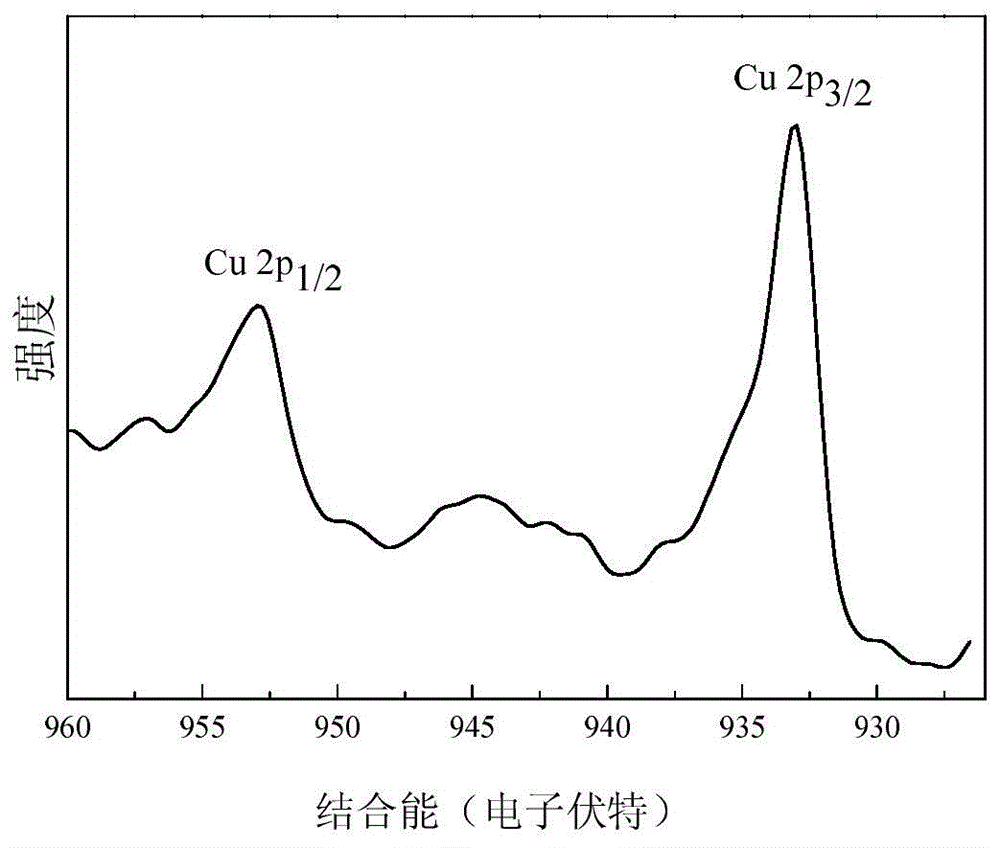

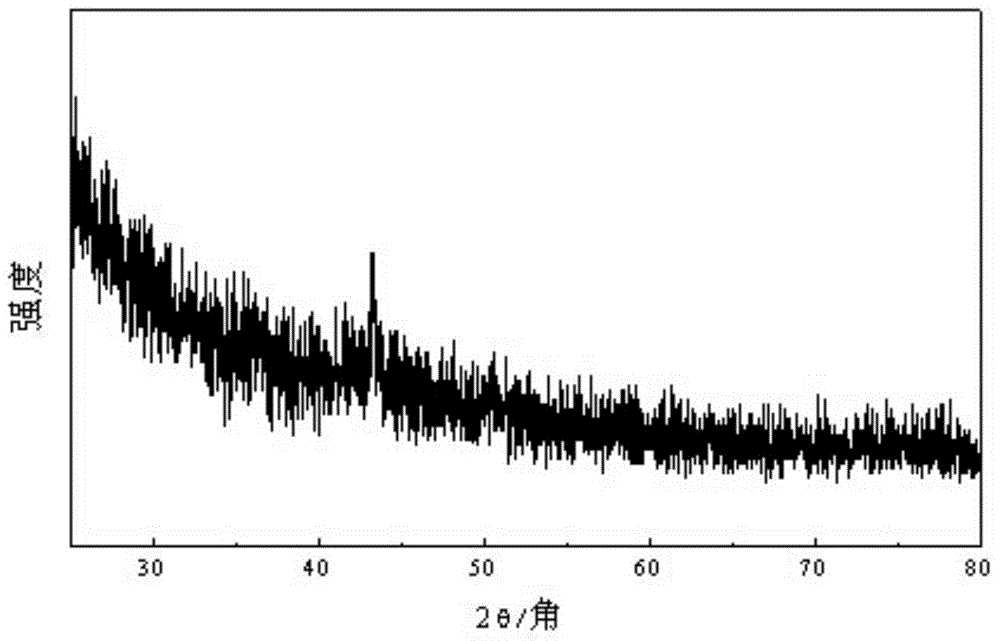

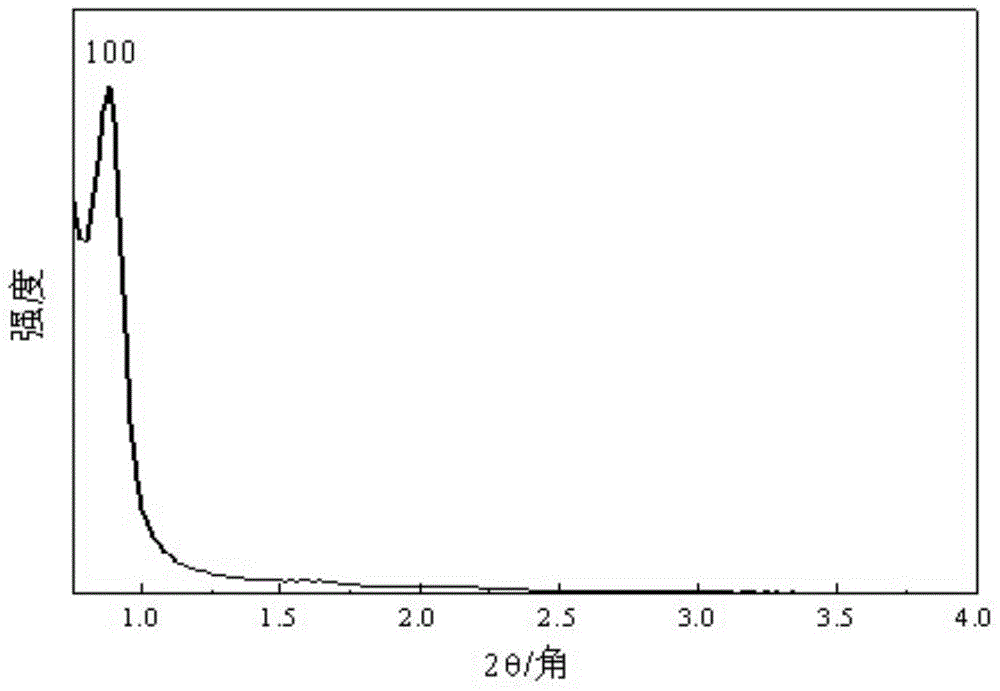

[0045] A series of characterizations are carried out to the obtained heterogeneous catalyst of embodiment 2, the results are shown in the attached Figure 1-Figure 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com