Method for Synthesizing Cement Dispersant by End Group Functionalized Polyfatty Acid Vinyl Ester Macromonomer

A fatty acid vinyl ester and synthetic cement technology, which is applied in the field of cement dispersants, can solve the problems of loss, spillage to the concrete industry, single raw material variety, etc., and achieve the effects of lower prices, low prices, and simple preparation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

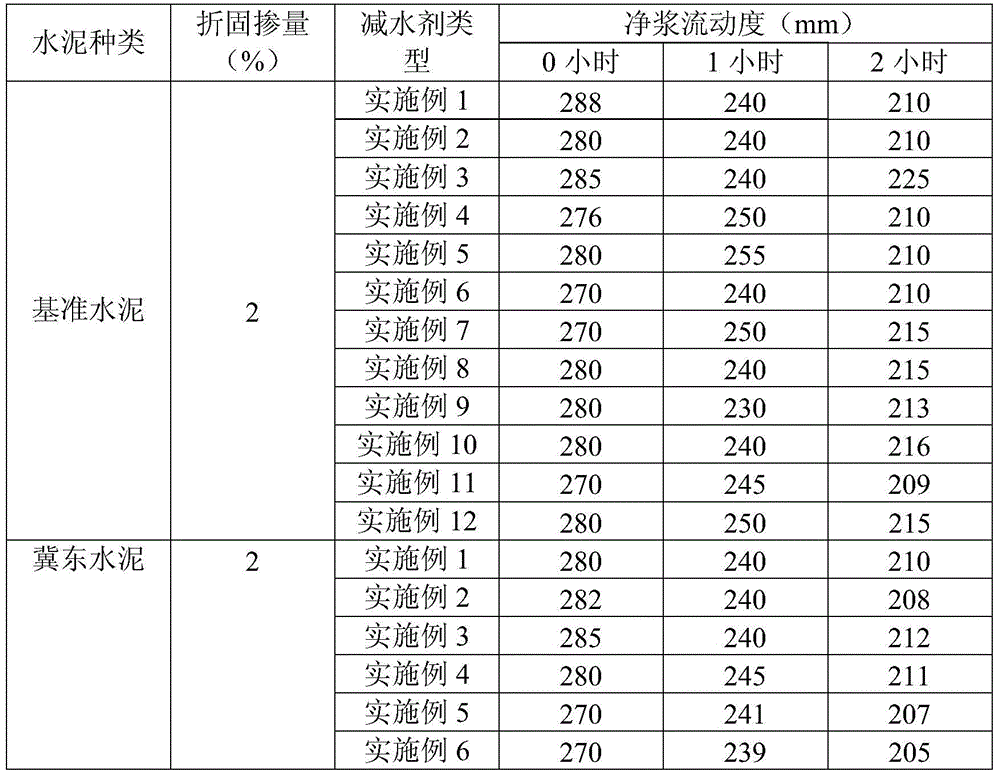

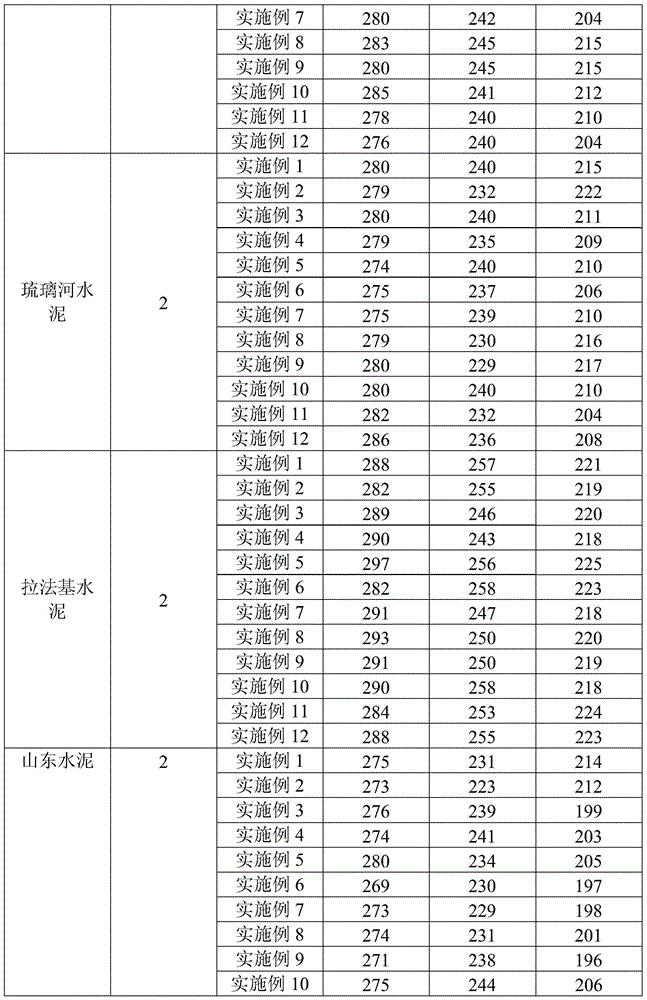

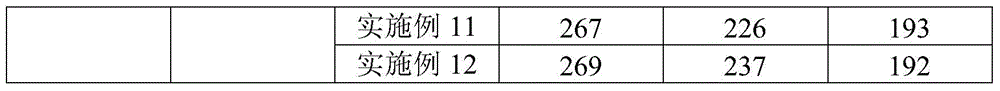

Examples

Embodiment 1

[0026] First, add 800g of toluene to the reactor, stir and raise the temperature to 80°C, add 3.12g of mercaptoethanol, then dropwise add the mixed solution of 100g of vinyl propionate and 3.28g of azobisisobutyronitrile for 1 hour, and the addition ends After continuing the constant temperature reaction for 5 hours, the toluene solvent was removed by distillation under reduced pressure to obtain polyvinyl propionate. Dissolve 100g of the obtained polyvinyl propionate in 1000g of sulfolane, stir and heat up to 50°C, add 5.56g of sodium hydroxide, react for 0.5 hours, then add 1.06g of 3-chloropropene and 0.94g of tetrabutylphosphine bromide in sequence , reacted for 2 hours, and then filtered the reaction solution to remove the generated sodium chloride, then purified 3 times with a mixed solvent of methanol-water with a volume ratio of 1:1, and then dried in vacuo. Add 100g of end-group-functionalized polyvinyl propionate into 160g of methanol, stir and heat up to 30°C, add 0...

Embodiment 2

[0028] After the cement dispersant solution with a concentration of 20% by mass obtained in Example 1 was stored at 6° C. for 15 days, its implementation effect was measured.

Embodiment 3

[0030] First, add 200g of methanol into the reactor, stir and heat up to 60°C, add 5.34g of mercaptopropanol, then add dropwise the solution of 100g of vinyl acetate and 5.75g of azobisisoheptanonitrile for 6 hours, and the dropwise addition ends After continuing the constant temperature reaction for 2 hours, the methanol solvent was distilled off under reduced pressure to obtain polyvinyl acetate. Dissolve 100 g of the obtained polyvinyl acetate in 100 g of dimethyl sulfoxide, stir and heat up to 30 ° C, add 2.17 g of potassium hydroxide, react for 5 hours, then add 1.48 g of 3-chloropropene and 0.62 g of tetrabutyl ammonium bromide, reacted for 1 hour, and then filtered the reaction solution to remove the generated potassium chloride, then purified 5 times with a mixed solvent of methanol-water with a volume ratio of 2:1, and then dried in vacuum. Add 100g of end-group-functionalized polyvinyl acetate into 160g of ethanol, stir and heat up to 40°C, add 0.58g of potassium hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com