Organic electroluminescent device and production method thereof

An electroluminescent device and electroluminescent technology, applied in the manufacturing of organic semiconductor devices, electro-solid devices, semiconductor/solid-state devices, etc., can solve the problems of poor stability, high driving voltage, low carrier mobility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

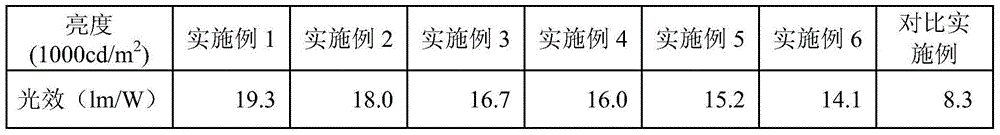

Embodiment 1

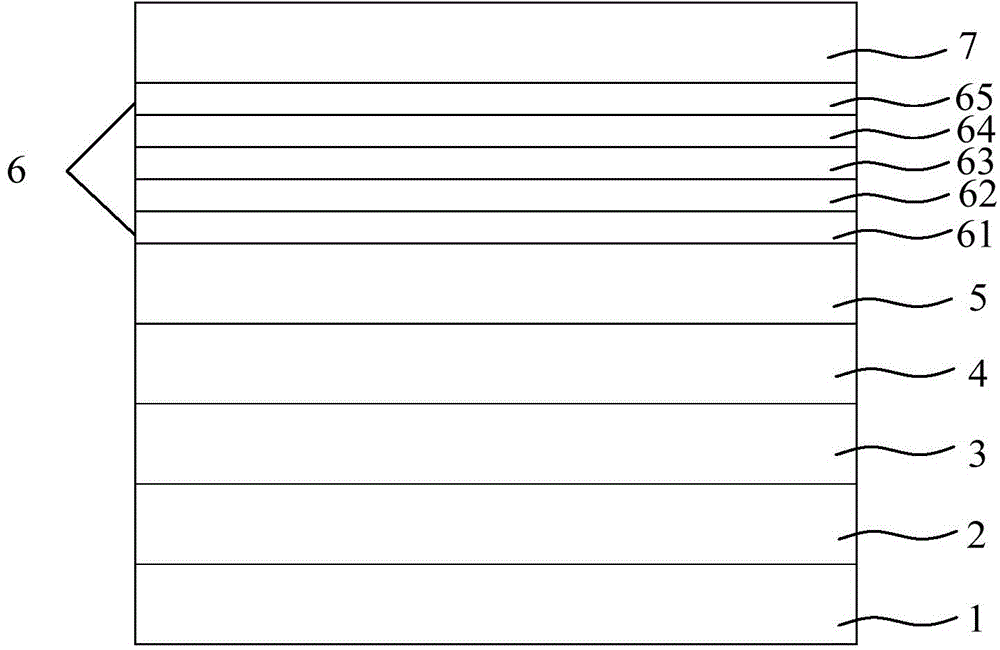

[0035] A method for preparing an organic electroluminescent device, comprising the following steps:

[0036] (1) Conductive anode 1 is made of indium tin oxide glass (ITO), and ultrasonicated with detergent, deionized water, acetone and ethanol for 5 minutes each to remove organic pollutants on the glass surface, cleaned and air-dried; The final ITO glass also needs surface activation treatment to increase the oxygen content on the ITO surface and improve the work function of the ITO surface; the thickness of the conductive anode 1 is 100nm; then the hole injection layer is prepared by vacuum evaporation on the conductive anode 1 2. Hole transport layer 3, light emitting layer 4 and electron transport layer 5;

[0037] The hole injection layer 2 is made of MoO 3 Hybrid material formed by doping N,N'-diphenyl-N,N'-bis(1-naphthyl)-1,1'-biphenyl-4,4'-diamine (NPB), MoO 3 The mass of the hole injection layer accounts for 30% of the mass of the hole injection layer, the thickness...

Embodiment 2

[0045] A method for preparing an organic electroluminescent device, comprising the following steps:

[0046] (1) Use indium tin oxide glass (ITO) as the conductive anode, and use detergent, deionized water, acetone and ethanol to ultrasonicate for 5 minutes each to remove organic pollutants on the glass surface, clean it and air dry it; The ITO glass also needs surface activation treatment to increase the oxygen content on the ITO surface and improve the work function of the ITO surface; the thickness of the conductive anode is 100nm; Transport layer, light emitting layer and electron transport layer;

[0047] The material of the hole injection layer is WO 3 Hybrid material formed by doping into 4,4',4''-tris(carbazol-9-yl)triphenylamine (TCTA), WO 3 The mass of the hole injection layer accounts for 25% of the mass of the hole injection layer, the thickness of the hole injection layer is 10nm, and the vacuum degree during evaporation is 5×10 -5 Pa, the evaporation rate is ...

Embodiment 3

[0055] A method for preparing an organic electroluminescent device, comprising the following steps:

[0056] (1) Use indium tin oxide glass (ITO) as the conductive anode, and use detergent, deionized water, acetone and ethanol to ultrasonicate for 5 minutes each to remove organic pollutants on the glass surface, clean it and air dry it; The ITO glass also needs surface activation treatment to increase the oxygen content on the ITO surface and improve the work function of the ITO surface; the thickness of the conductive anode is 100nm; Transport layer, light emitting layer and electron transport layer;

[0057] The material of the hole injection layer is V 2 o 5 Doped to 4,4'-bis(9-carbazole)biphenyl (CBP) to form a hybrid material, V 2 o 5 The mass of the hole injection layer accounts for 35% of the mass of the hole injection layer, the thickness of the hole injection layer is 15nm, and the vacuum degree during evaporation is 5×10 -5 Pa, the evaporation rate is

[0058...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com