High-carbon-based soil additive prepared from fermented soybean straw

A soybean straw and additive technology, which is applied in the field of high carbon-based soil additives, can solve the problems of low decomposition efficiency, long fermentation time, poor pertinence, etc., and achieve the effects of improving product quality, repairing soil, and enhancing cold resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

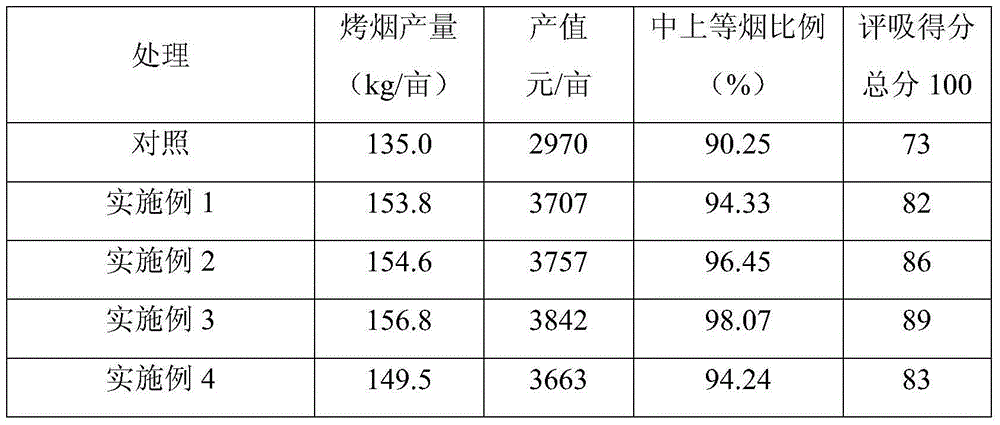

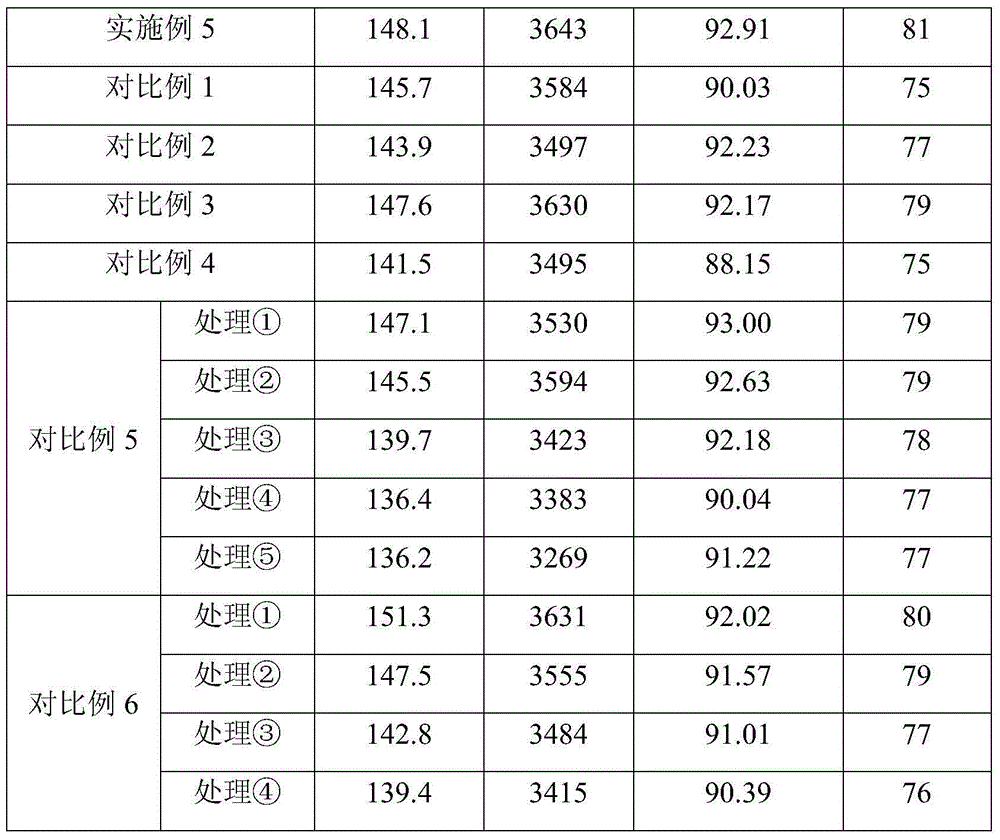

Examples

Embodiment 1

[0028] A soil high-carbon-based additive prepared by the following method: cutting 100kg of soybean straw into 10-30cm segments as a degradation raw material, adding 0.8% of straw weight compound bacteria to it, adding 30kg of water, and fermenting for 2 Every 8 days, the overturning is carried out once; every 8 days, the overturning is performed twice in total to obtain the soil high-carbon-based additive.

[0029] Wherein, the preparation method of the composite bacteria is:

[0030] S1. Activate Phanerochaete chrysosporium, Trichoderma konii, Paracoccus denitrificans, Rhodococcus, and Filamentous bacteria succinicum respectively, and cultivate until the concentration of viable bacteria in the bacterial solution is 2×10 9 piece / gram;

[0031] S2. get respectively 114g Phanerochaete chrysosporium bacterium liquid, 190g Trichoderma konshii bacterium liquid, 190g denitrification paracoccus bacterium liquid, 76g Rhodococcus bacterium liquid, 229g succinic filamentous bacteria l...

Embodiment 2

[0033]A soil high-carbon-based additive prepared by the following method: cutting 100kg of soybean stalks into 10-30cm segments as degradation raw materials, adding complex bacteria with 1.2% of the weight of the stalks to it, adding 35kg of water, and fermenting In 2 days, overturn once; and then overturn once every 10 days, and overturn twice in total to obtain the soil high-carbon-based additive.

[0034] Wherein, the preparation method of the composite bacteria is:

[0035] S1. Activate Phanerochaete chrysosporium, Trichoderma konii, Paracoccus denitrificans, Rhodococcus, and Filamentous bacteria succinicum respectively, and cultivate them until the concentration of viable bacteria in the bacterial solution is 2×10 9 piece / gram;

[0036] S2. get respectively 109g Phanerochaete chrysosporium bacterium liquid, 218g Trichoderma konshii bacterium liquid, 273g denitrification paracoccus bacterium liquid, 164g Rhodococcus bacterium liquid, 436g succinic filamentous bacteria liq...

Embodiment 3

[0038] A soil high-carbon-based additive prepared by the following method: cutting 100kg of soybean straw into 10-30cm segments as a degradation raw material, adding 2% of straw weight compound bacteria to it, adding 40kg of water, and fermenting for 2 Every 12 days, carry out overturning once; then overturn once every 12 days, totally overturn twice, obtain described soil high carbon base addition.

[0039] Wherein, the preparation method of the composite bacteria is:

[0040] S1. Activate Phanerochaete chrysosporium, Trichoderma konii, Paracoccus denitrificans, Rhodococcus, and Filamentous bacteria succinicum respectively, and cultivate until the concentration of viable bacteria in the bacterial solution is 10 9 piece / gram;

[0041] S2. Get respectively 286g Phanerochaete chrysosporium bacterium liquid, 381g Trichoderma konshii bacterium liquid, 571g denitrification paracoccus bacterium liquid, 190g Rhodococcus bacterium liquid, 571g succinic filamentous bacteria liquid (pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com