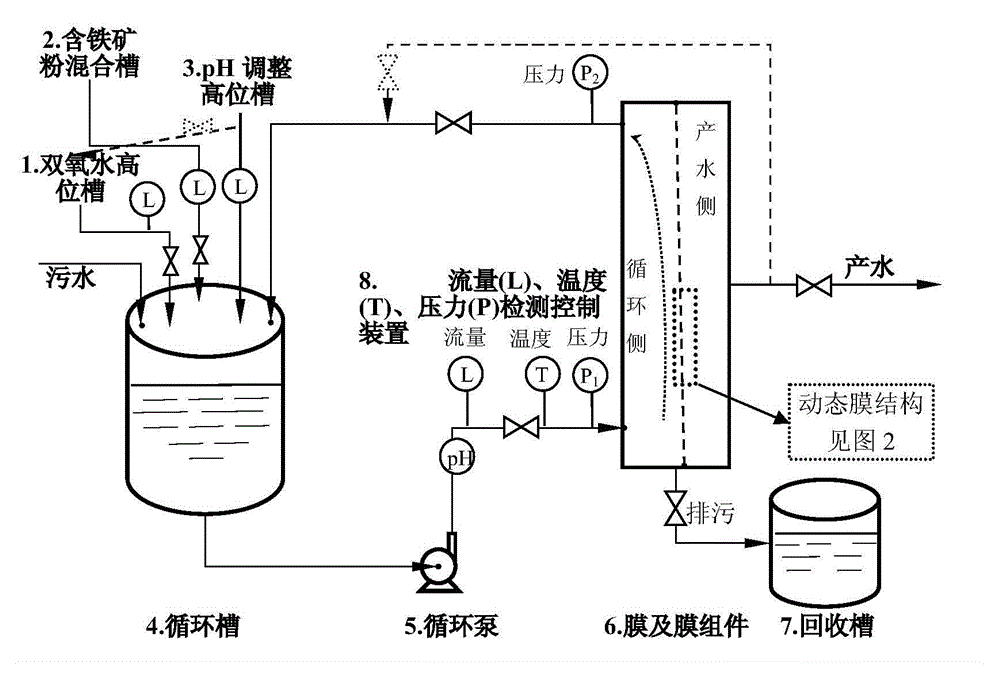

Online chemical oxidation dynamic membrane wastewater treatment system

A wastewater treatment system and technology of the treatment system, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., to achieve the effects of low operating costs, simplified process units, and simple operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

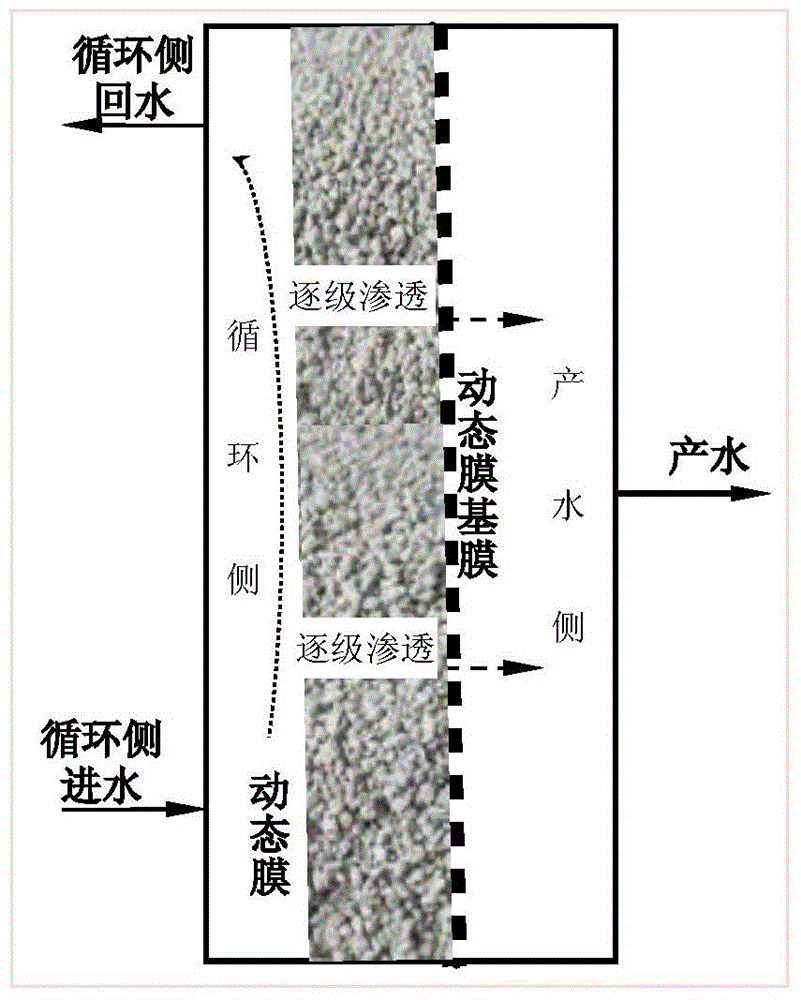

Method used

Image

Examples

Embodiment 1

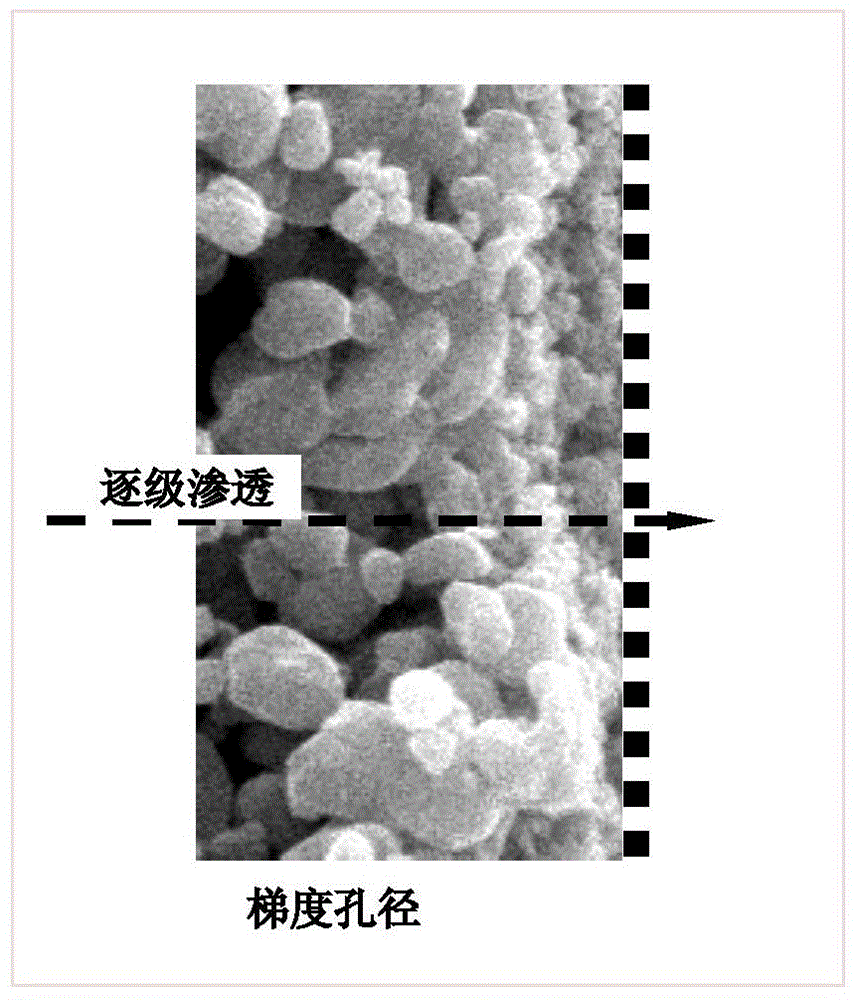

[0021] First add hydrogen peroxide in the hydrogen peroxide head tank (1), keep the pH value of 3.0-5.0, to prevent the device from decomposing before operation; add 2000 mesh hematite powder (basement membrane aperture is 0.5-3.0 microns), add 10% caustic soda (wastewater is pesticide waste water, acid concentration is higher, COD Cr Higher), and then dosing in proportion to the circulation tank (4) where the pesticide wastewater has been stored. After the liquid level reaches the operating conditions, start the circulation pump (5) to supply liquid to the membrane and membrane module (6), and start the circulation filtration operation , the membrane used is a 19-channel ceramic microfiltration membrane with a pore size of 0.5-3.0 microns. The ceramic membrane in the module is placed vertically, the water enters the bottom of the circulation side, and the water exits the upper part. Every 19 membrane tubes form a module, and the circulation return valve is opened. And accordi...

Embodiment 2

[0023]Add hydrogen peroxide and an appropriate amount of acid in the hydrogen peroxide head tank (1), keep the pH value at 3.0-5.0, so as not to decompose the hydrogen peroxide; add ferric oxide ( basement membrane pore size is 0.05-0.5 micron), add 10% hydrochloric acid (treatment of flax production wastewater, strong alkalinity) in the pH adjustment head tank (3), and then add in proportion to the circulation tank that has stored the flax production wastewater ( 4), start the circulating pump (5), supply liquid to the membrane and the membrane module (6), and start the circulating filtration operation. The membrane used is a plate-type ceramic microfiltration membrane with a pore size of 0.05-0.5 microns, and the ceramic membrane in the module is placed horizontally. The sheet ceramic membrane is a unit, and the circulation return valve is opened, and the parameters are controlled and adjusted by the detection and control device (8) of flow (L), temperature (T), pressure (P),...

Embodiment 3

[0025] Add hydrogen peroxide and an appropriate amount of hydrochloric acid in the hydrogen peroxide head tank (1), keep the pH value at 3.0-5.0, and prevent the hydrogen peroxide from decomposing; Membrane pore size is 0.01-0.05 micron), add 10% hydrochloric acid (the raw material wastewater is printing and dyeing wastewater, alkaline) into the pH adjustment head tank (3), and then add in proportion to the circulation tank (4) where the printing and dyeing wastewater has been stored , start the slurry pump (5), supply liquid to the ceramic ultrafiltration membrane module (6), and start circulating filtration operation. The membrane used is a 37-channel ceramic ultrafiltration membrane with a pore size of 0.01-0.05 microns, and every 19 ceramic membrane tubes form one Unit, open the circulation return valve, and according to the operating parameters, the parameters are controlled and adjusted by the detection and control device (8) of flow (L), temperature (T), pressure (P), pH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com