Leisure dairy product and preparation method thereof

A technology for dairy products and milk solids, applied in dairy products, milk preparations, applications, etc., can solve the problems of non-compliance with the development direction of dairy products, restrictions on yogurt sales and consumption, and relatively high requirements for the sales environment, and achieve good nutrition and health care functions. , easy to carry and store, low requirements for sales environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

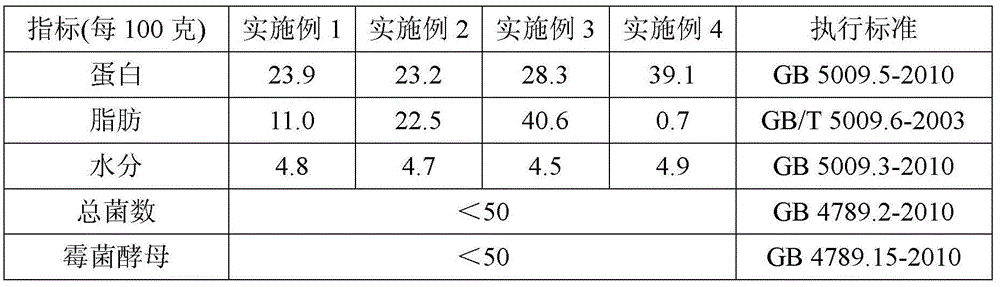

Embodiment 1

[0032] This embodiment provides a leisure dairy product (original flavor), and every 1000 parts by weight of raw materials includes: 200 parts by weight of raw milk, 200 parts by weight of maltitol, 100 parts by weight of anhydrous butter, 200 parts by weight of skimmed milk powder, whey 100 parts by weight of powder (WPC), 80 parts by weight of starch, 20 parts by weight of sodium bicarbonate, 0.1 part by weight of lactobacillus streptococcus, and the balance is water.

[0033] The above leisure dairy product (plain flavor) is prepared by the following steps:

[0034] Step 1: Add raw milk, maltitol, anhydrous butter, sodium bicarbonate, lactobacillus streptococcus, 60wt% whey powder (WPC) and skimmed milk powder to the ingredient water at 20-30°C, in a stand mixer After mixing evenly, start beating, the speed is increased from 40r / min to 400r / min and then reduced to 40r / min, and lasts for 10±1min to obtain the material after beating;

[0035] Step 2: At the speed of 40r / min,...

Embodiment 2

[0041] This example provides a leisure dairy product (yogurt flavor), and every 1000 parts by weight of raw materials includes: 100 parts by weight of fermented milk, 20 parts by weight of sucrose, 10 parts by weight of fruit grape syrup, 700 parts by weight of whole milk powder, 100 parts by weight of concentrated milk protein powder (MPC), 20 parts by weight of starch, 1 part by weight of disodium hydrogen phosphate, 1 part by weight of sodium bicarbonate, 1 part by weight of lactobacillus streptococcus, and the balance is water.

[0042] Wherein, the fermented milk is obtained by fermenting Lactobacillus bulgaricus and Streptococcus thermophilus as the base bacteria, adding Bifidobacterium, Lactobacillus paracasei and Lactococcus lactis as starters. Based on the composition of the above raw materials, the base bacteria The addition amount of the two kinds of basic bacteria is 100DCU / ton, and the addition amount of other bacteria is 50DCU / ton.

[0043] The above leisure dair...

Embodiment 3

[0051] This embodiment provides a leisure dairy product (high fat), and every 1000 parts by weight of raw materials includes: 10 parts by weight of fermented milk, 20 parts by weight of maltitol, 10 parts by weight of fruit grape syrup, 400 parts by weight of anhydrous cream, 400 parts by weight of concentrated milk protein powder (MPC), 30 parts by weight of starch, 1 part by weight of polydextrose, 10 parts by weight of sodium bicarbonate, 0.1 part by weight of lactobacillus streptococcus, and the balance is water.

[0052] Wherein, the fermented milk is obtained by fermentation with Lactobacillus bulgaricus and Streptococcus thermophilus as the base bacteria, and Lactobacillus paracasei as the starter. Based on the composition of the above raw materials, the addition amount of the base bacteria is 400 DCU / ton, The two basic bacteria are added in any proportion, and the amount of Lactobacillus paracasei added is 50DCU / ton.

[0053] The leisure dairy product (high fat) descri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com