Catalyst for carbonylation of dimethyl ether to prepare methyl acetate and its preparation method and use

A methyl acetate and catalyst technology, applied in the field of catalytic chemistry, can solve the problems such as inability to selectively remove twelve-membered ring pore channels, easy collapse of molecular sieve structure, large mass transfer resistance and easy carbon deposition, etc. Reduced maintenance costs and long catalyst life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides the preparation method of above-mentioned catalyst:

[0033] For the catalyst containing the hydrogen type mordenite molecular sieve of silicon tetrachloride vapor dealumination, its main preparation steps are as follows:

[0034] a) contacting hydrogen-form mordenite with silicon tetrachloride vapor at 500-700° C. to obtain the hydrogen-form mordenite molecular sieve dealuminated by silicon tetrachloride vapor;

[0035] b) drying and calcining the hydrogen-type mordenite molecular sieve obtained in step a) after steam dealumination of silicon tetrachloride to obtain the catalyst for the carbonylation of dimethyl ether to produce methyl acetate.

[0036] The above-mentioned catalyst containing mesoporous, its main preparation steps are as follows:

[0037] a) contacting hydrogen-form mordenite with silicon tetrachloride vapor at 500-700° C. to obtain the hydrogen-form mordenite molecular sieve dealuminated by silicon tetrachloride va...

Embodiment 1

[0081] Example 1: Preparation of silicon tetrachloride vapor dealuminated mordenite molecular sieve

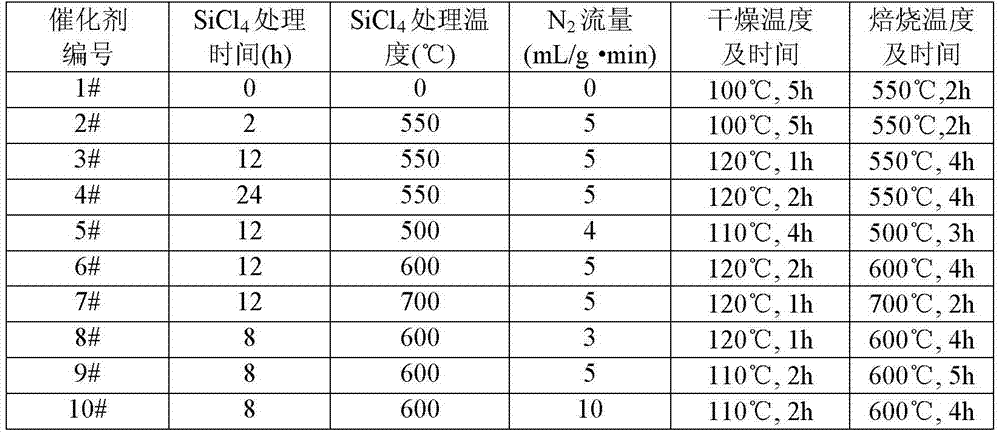

[0082] Weigh 1 g of hydrogen-type mordenite, fix both ends in a quartz tube with quartz wool, and let 273K saturated silicon tetrachloride vapor carried by nitrogen gas into it. The obtained solid sample is washed with deionized water, separated by filtration, dried and calcined to obtain the desired catalyst for carbonylation of dimethyl ether to produce methyl acetate. The temperature and time of silicon tetrachloride vapor treatment, the temperature and time of solid sample drying and roasting are shown in Table 1.

[0083] Table 1

[0084]

Embodiment 2

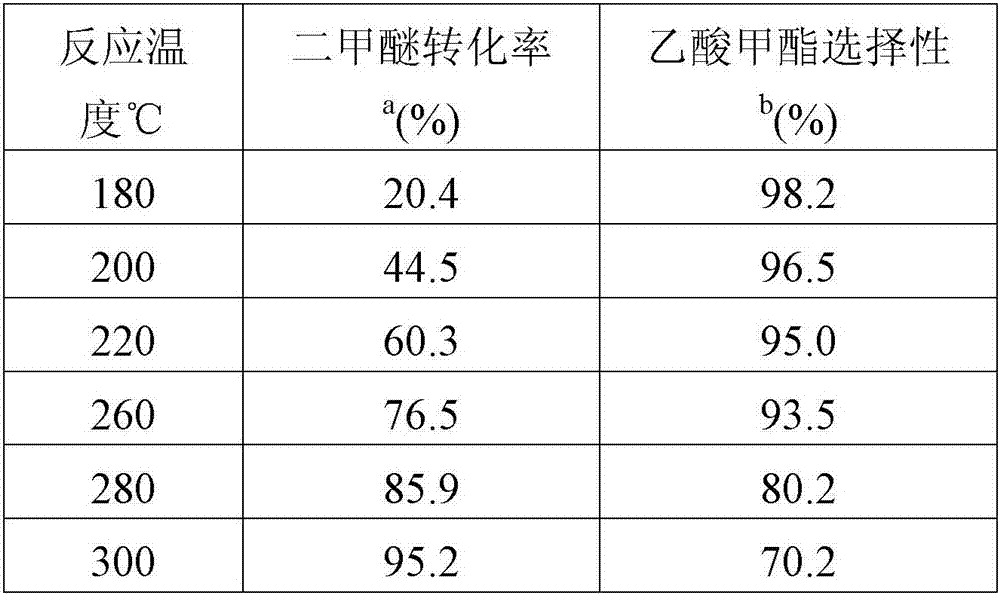

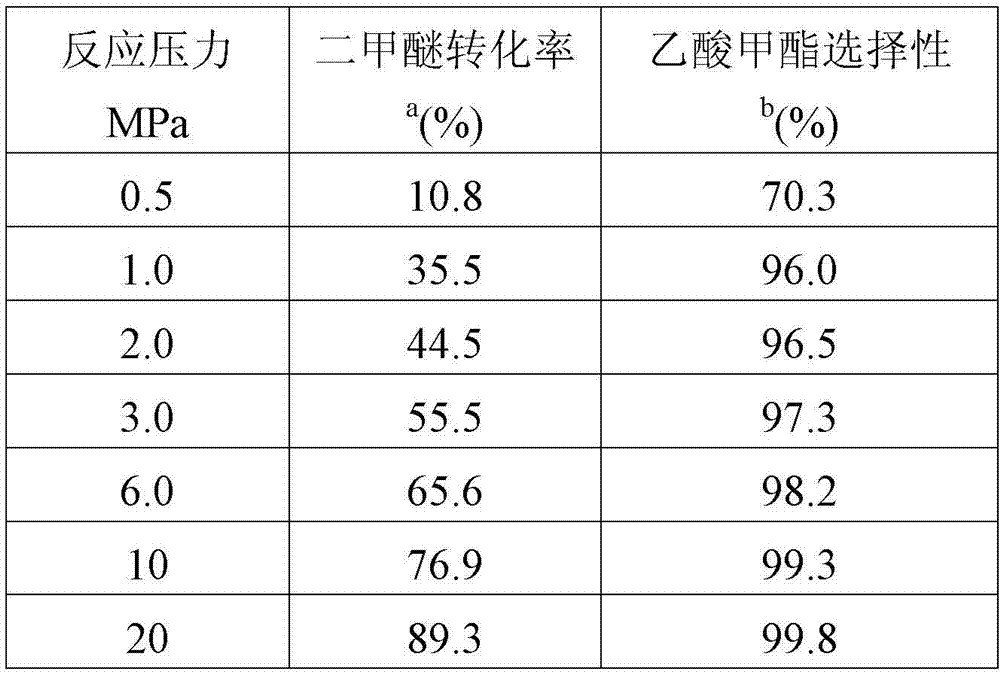

[0085] Embodiment 2: the reaction performance evaluation of catalyst

[0086] The 40-60 mesh sample obtained by tableting, crushing and sieving the catalyst powder obtained in Example 1 was used in the carbonylation of dimethyl ether to produce methyl acetate for performance measurement. 1.0 g of each catalyst was loaded into the reactor respectively, and the mixed gas of dimethyl ether, hydrogen, and carbon monoxide was passed through the reactor at a temperature of 200° C., a pressure of 2 MPa, and a gas volume flow rate of 1500 ml / g / h. Among them, the gas flow rate F(H 2 +DME)=16.4ml / min, DME / CO / H 2 =5 / 35 / 60 (volume ratio). The results of the catalyst reactions are listed in Table 2.

[0087] Table 2

[0088] catalyst Dimethyl ether conversion rate a (%)

Methyl acetate selectivity b (%)

life c (h)

1# 50.5 94.4 9.3 2# 48.1 94.3 8.0 3# 40.3 97.2 14.5 4# 44.2 98.8 17.8 5# 46.3 94.3 10.1 6# 44.5 96.5 20.1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com