Method and device for processing polymer-contained waste liquid and fracturing flow-back fluid

A fracturing flowback fluid and treatment method technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Reuse and re-injection, adverse effects of dosing agents, etc., to achieve the effect of convenient equipment processing and transportation, realizing waste liquid resource utilization, and saving transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

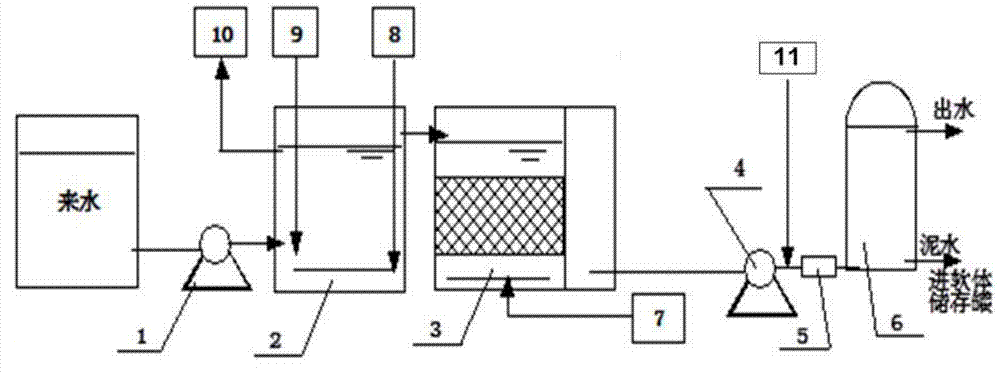

[0035] like figure 1 As shown, it is a schematic diagram of the treatment device for polymer-containing waste fluid and fracturing flowback fluid provided in this example. As can be seen from the figure, the treatment device consists of a lift pump 1, an ultrasonic generator 9, an ozone generator 8, a sewage reaction tank 2, a multi-media activated carbon device 3, an aeration device 7, a secondary lift pump 4, and a pipeline mixing device 5, dosing device 11 and coagulation-filtration-precipitation integrated device 6, the sewage reaction tank 2, multi-media activated carbon device 3 and coagulation-filtration-precipitation integrated device 6 are connected in sequence through pipelines, and the The ultrasonic generator 9 is placed next to the sewage reaction tank 2, the ozone generator 8 is placed in the sewage reaction tank 2, the carrier activated carbon catalyst is fixed in the multi-media activated carbon device 3, and the aeration device 7 is placed in the At the botto...

Embodiment 2

[0037] The processing device is as described in Example 1.

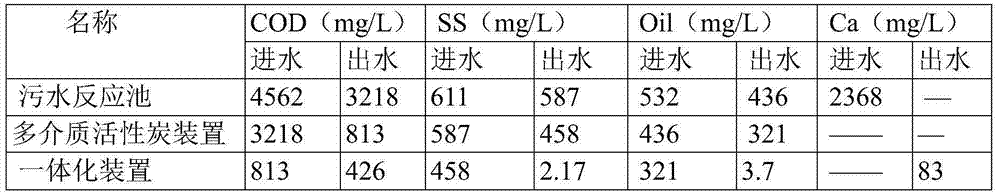

[0038] Fracturing fluid treatment volume 1m 3 / h, influent water quality: water temperature 48°C, pH=8.6, oil content 532mg / L, COD 4562mg / L, suspended matter: 611mg / L. The treatment method is as follows: the ultrasonic frequency in the sewage reaction tank is controlled at 23kHz, the dosage of ozone is 12mg / L, and the residence time is 30min; the dosage of the catalyst (copper-loaded activated carbon) in the multi-media activated carbon device is 0.6m 3 , the aeration is controlled at an air-to-water ratio of 32:1. Coagulation-sedimentation-filtration integrated device front-end agent dosage is: organic polymer flocculant (polymer polyacrylamide) is 80mg / L, water purifier (OTC-A) is 65mg / L, coagulant aid ( Cationic polyacrylamide) is 0.5mg / L. The working time of the device is 52min. The effluent reaches the standard of "Methods for Performance Evaluation of Water-Based Fracturing Fluids" (SY / T5107-2005).

[0039...

Embodiment 3

[0044] The processing device is as described in Example 1.

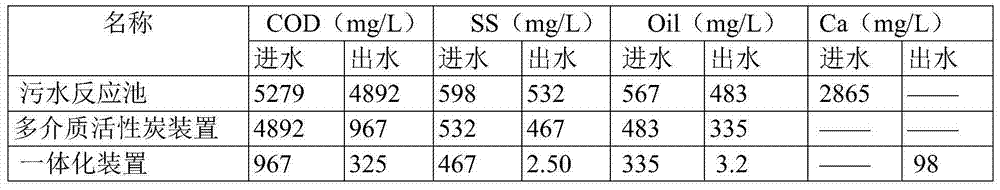

[0045] Polymerized sewage treatment capacity 1m 3 / h, influent water quality: water temperature 45°C, pH=8.9, oil content 567mg / L, COD 5279mg / L, suspended matter: 598mg / L. The specific treatment method is that the ultrasonic frequency in the sewage reaction tank is controlled at 25kHz, the dosage of ozone is 14.5mg / L, and the residence time is 30min; the dosage of cobalt-loaded activated carbon in the multi-media activated carbon device is 0.65m 3 , Aeration is controlled at an air-to-water ratio of 35:1. Coagulation-sedimentation-filtration integrated device front-end agent dosage is: organic polymer flocculant (acrylamide and dimethylaminoethyl methacrylate copolymer) is 75mg / L, water purifier (OTC-B) is 55mg / L, coagulant aid (anionic polyacrylamide) is 1mg / L. The working time of the device is 48min. The effluent meets the standards of SYT 5329-2012 Recommended Indexes and Analysis Methods for Injection Water Q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com