Method for preparing 1,1,1,3,3,3-hexafluoroacetone by gas phase fluorination

A gas-phase fluorination and hexafluoroacetone technology, applied in the preparation of carbon-based compounds, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of difficult separation of products, high reaction temperature, production and use of human and environmental hazards, etc. , to achieve the effect of safety and environmental protection, simple preparation process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

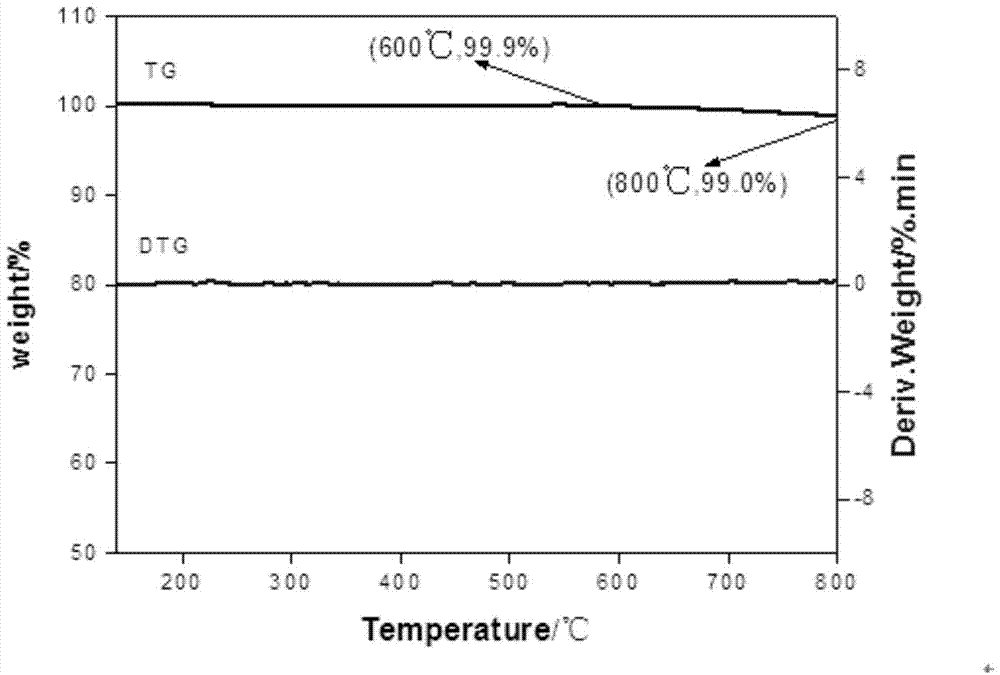

Image

Examples

Embodiment 1

[0032] 64.8g of Fe(NO 3 ) 3 and 1.06 g of CuCl 2 Dissolved in 100ml of distilled water to make an impregnation solution, then 100g of Al 2 o 3 The carrier is placed in the impregnation solution, and after immersion for 12 hours, it is dried on a rotary evaporator at 80°C, and the water is evaporated to dryness to obtain a fluorination catalyst in which the weight of the Fe element is 15% of the weight of the carrier and the weight of the Cu element is 0.5% of the weight of the carrier. the precursor body. The precursor of the fluorination catalyst was roasted in a muffle furnace at 350°C for 8 hours, then loaded into a tubular reactor, heated to 200°C, fed with hydrogen fluoride gas for fluorination for 1 hour, and then heated at a rate of 1°C / min to Continue fluorination at 350°C for 8 hours to obtain a fluorination catalyst.

[0033] Add 60 ml of the fluorination catalyst prepared by the above method into a carbon steel pipe with an inner diameter of 38mm, feed HF and 1...

Embodiment 2

[0035] The present embodiment carries out according to the same step as embodiment 1, and the difference is that Fe(NO 3 ) 3 The amount was changed to 43.2g, the drying temperature was changed to 50°C, and the calcination temperature was changed to 450°C to obtain a fluorinated catalyst precursor in which the weight of the Fe element was 10% of the weight of the carrier, and the weight of the Cu element was 0.5% of the weight of the carrier. The product of this embodiment is analyzed by gas chromatography, and the conversion rate of 1,1,1,3,3,3-hexachloroacetone is 63%, and the selectivity of 1,1,1,3,3,3-hexafluoroacetone It is 96.1%.

Embodiment 3

[0037] The present embodiment carries out according to the same step as embodiment 1, and the difference is that Fe(NO 3 ) 3 Change it to 15.5g of iron acetate to prepare a fluorination catalyst precursor in which the weight of Fe element is 5% of the weight of the carrier, and the weight of Cu element is 0.5% of the weight of the carrier. The product of the present embodiment is analyzed by gas chromatography, and the conversion rate of 1,1,1,3,3,3-hexachloroacetone is 60%, and the selectivity of 1,1,1,3,3,3-hexafluoroacetone 95.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com