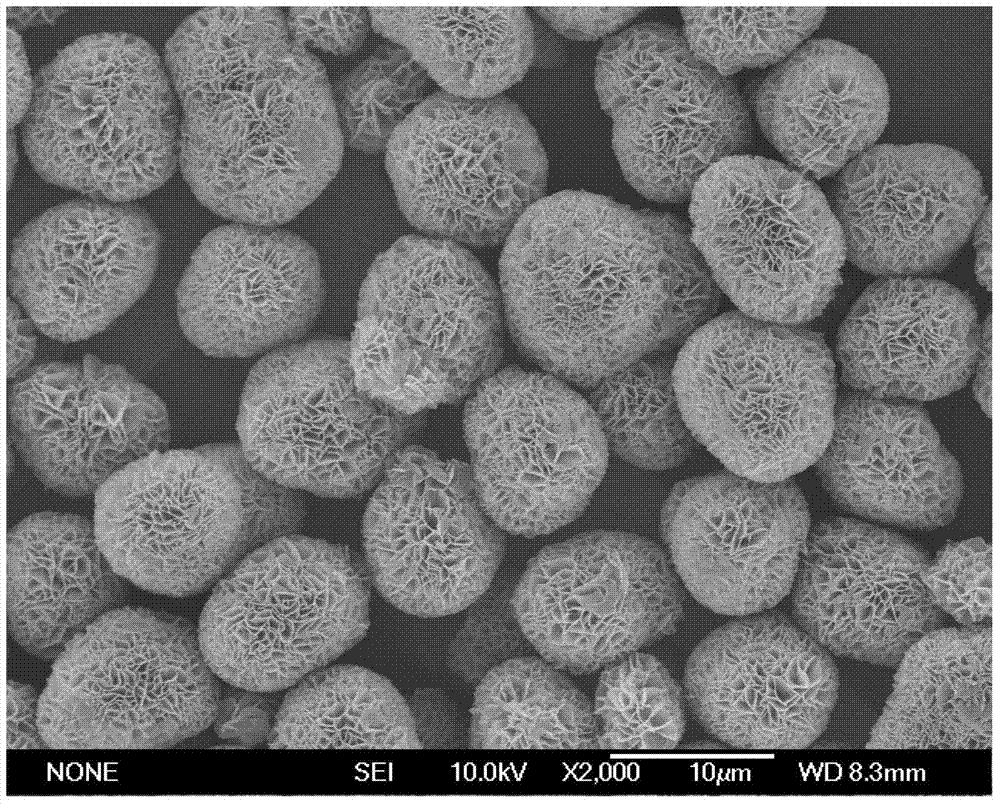

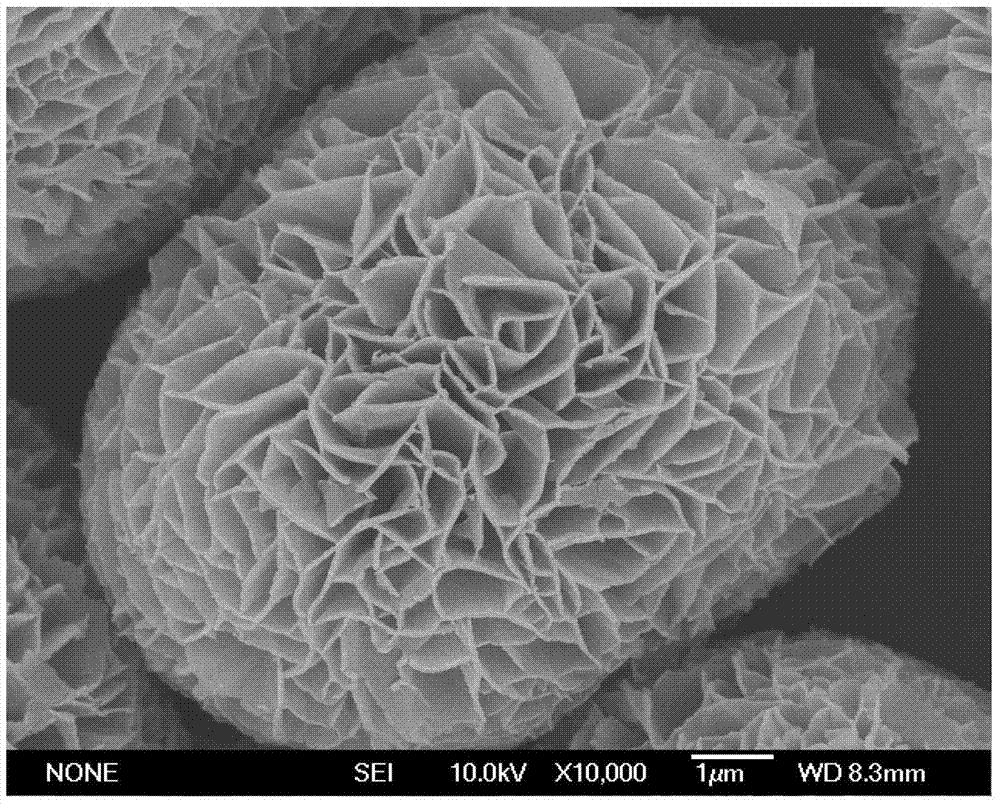

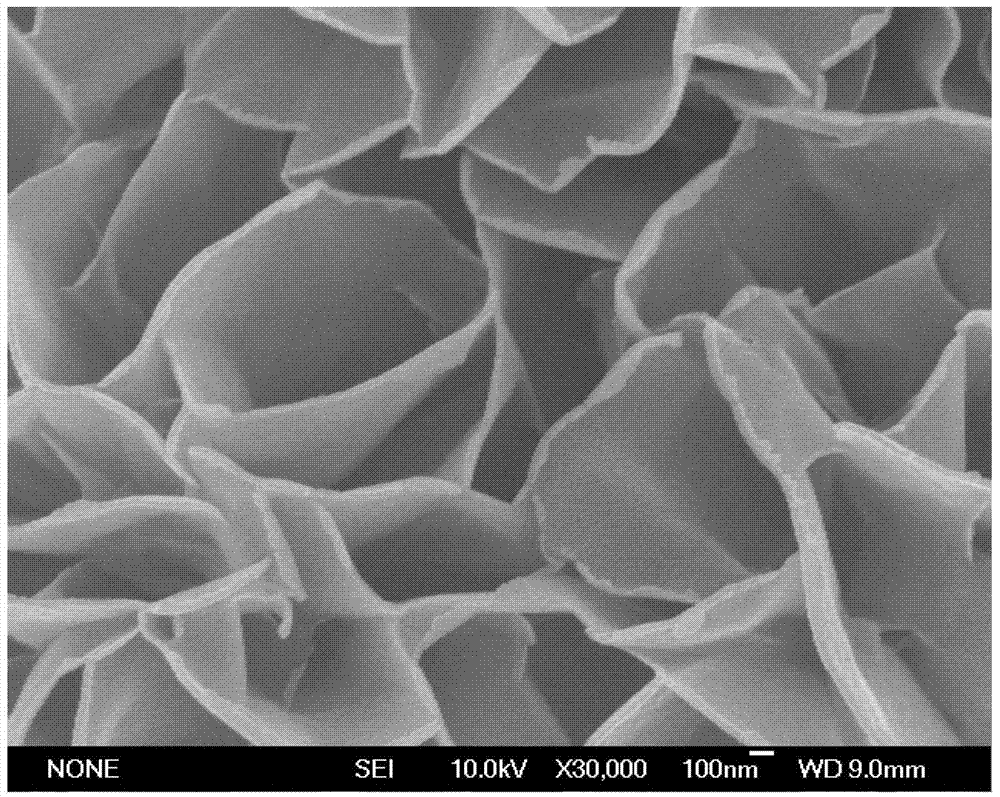

Method for producing flower-like sphere type nanometer magnesium hydroxide with characteristics of light weight and high specific surface area

A nano-magnesium hydroxide, magnesium hydroxide technology, applied in the direction of magnesium hydroxide, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as low purity, complicated operation, and large particle size of the product. Achieve the effects of easy mass synthesis, simple equipment, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A. Prepare a mixed solution of ethanol and water at a ratio of 1:1 in a reaction vessel, prepare a 0.5mol / L magnesium sulfate solution in this mixed solution, add 30% (mass fraction) of glycerol, and mix well.

[0063] B. Prepare a mixed solution of ethanol and water at a ratio of 1:4 in a container, and prepare a 1mol / L sodium hydroxide solution in this mixed solution.

[0064] C. At room temperature, slowly drop 1L of the solution described in B into 1L of the solution described in A, and at the same time stir the reaction at a stirring speed of 700 rpm for 20 hours, and a white precipitate was obtained in the reaction vessel A. After aging for 2 hours, the white precipitate Filter, wash with deionized water several times until there is no sulfate ion, then wash with absolute ethanol to obtain a white solid, dry the white solid at 60°C to constant weight, and obtain a light, high specific surface area (90m 2 / g), curd-shaped nano-magnesium hydroxide.

Embodiment 2

[0066] A. Prepare a 0.5 mol / L magnesium sulfate aqueous solution in a reaction vessel, add 30% (mass fraction) glycerol, and mix well.

[0067] B. Prepare 1mol / L sodium hydroxide aqueous solution in a container.

[0068] C. At room temperature, slowly drop 1L of the solution described in B into 1L of the solution described in A, while stirring the reaction at a stirring speed of 700 rpm for 15 hours, a white precipitate was obtained in reaction vessel A, and after aging for 1.5 hours, the white Filter the precipitate, wash with deionized water for several times until there is no sulfate ion, and then wash with absolute ethanol to obtain a white solid. Dry the white solid at 100°C to constant weight to obtain a light, high specific surface area ( 110m 2 / g), curd-shaped nano-magnesium hydroxide.

Embodiment 3

[0070] A. Prepare a 0.5 mol / L magnesium chloride aqueous solution in a reaction vessel, add 15% (mass fraction) glycerol, and mix well.

[0071] B. Prepare a 1mol / L potassium hydroxide aqueous solution in a container, add 15% (mass fraction) glycerol, and mix well.

[0072] C. At room temperature, slowly drop 1L of the solution described in B into 1L of the solution described in A, and at the same time stir the reaction at a stirring speed of 700 rpm for 8 hours, and a white precipitate was obtained in the reaction vessel A. After aging for 3 hours, the white precipitate Centrifugal cleaning, washing several times with deionized water until there is no chloride ion, and then washing once with absolute ethanol to obtain a white gel-like solid, dry the white solid at 150°C to constant weight to obtain a light, high specific Surface area (70m 2 / g), curd-shaped nano-magnesium hydroxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com