Fosthiazate-containing pesticide fertilizer granule with water soluble function

A medicinal fertilizer granule and a technology containing thiazophosphine, applied in fertilization devices, fertilizer mixtures, layered/coated fertilizers, etc., can solve the problems of integrated technical solutions such as unattended, and achieve the effect of easy operation and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

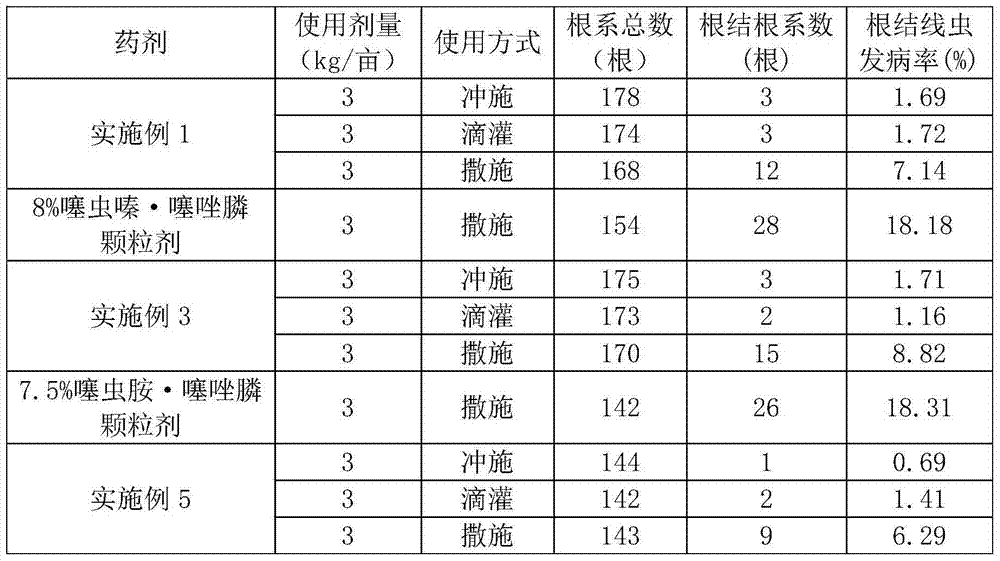

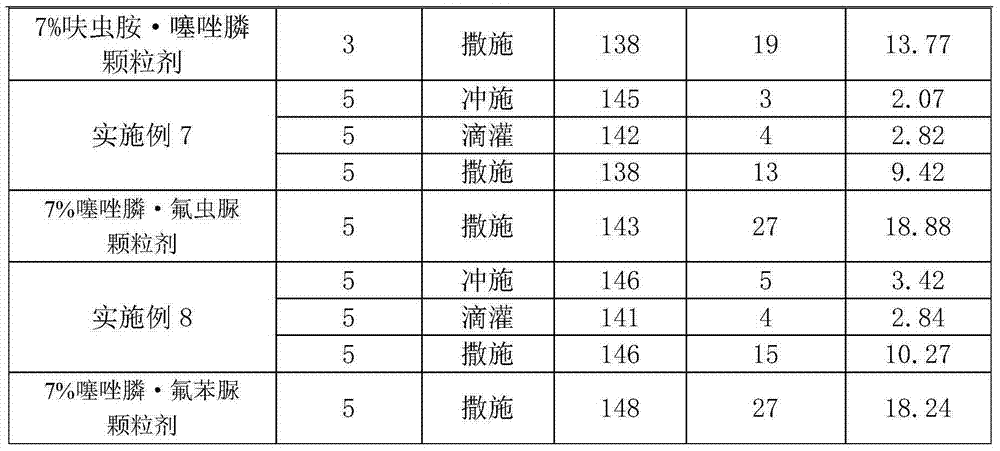

Examples

Embodiment 1

[0028] Embodiment 1: 8% thiamethoxam · thiazophos medicinal fertilizer granules (2.5:5.5)

[0029] The medicinal fertilizer granule formulation of the present embodiment consists of: the active ingredient content is 25.5kg of the original drug of thiamethoxam of 98%, the active ingredient content is 64.7kg of the original drug of thiazophosphine of 85%, white carbon black 22kg, humic acid 35kg, 5kg of microbial fermentation residue, 150kg of calcium ammonium nitrate, and 697.8kg of high-tower nitrosulfur-based compound fertilizer.

[0030] The specific preparation process steps of Yaofei Granules are:

[0031] ① Use 22kg of white carbon black to fully absorb 64.7kg of thiazophosphine with an active ingredient content of 85% in a double-helix stirred tank, and then add 25.5kg of thiamethoxam with an active ingredient content of 98% In the double-helix stirred tank, after being fully mixed and uniform, it is prepared into a 200-300-mesh powder combination through a jet mill, an...

Embodiment 2

[0034] Embodiment 2: 1.6% thiamethoxam·thiazolysin fertilizer granule (0.5:1.1)

[0035] The medicinal fertilizer granule formulation of the present embodiment consists of: active ingredient content of 98% thiamethoxam former drug 5.1kg, active ingredient content of 85% thiazophosphonic former drug 13.0kg, white carbon black 5kg, amino oligosaccharin powder 5kg, humic acid 30kg, urea 80kg, high-tower nitrosulfur-based compound fertilizer 861.9kg.

[0036] The specific preparation process steps of Yaofei Granules are:

[0037] ①Use 5 kg of white carbon black to fully absorb 13.0 kg of thiazophosphine with an active ingredient content of 85% in a double-helix stirred tank, and then add 5.1 kg of thiamethoxam with an active ingredient content of 98% In the double-helix stirring tank, after fully mixing evenly, it is prepared into a powder combination of 200-300 mesh through a jet mill, and it is ready for use.

[0038] ② Mix 80kg of urea, 861.9kg of high-tower nitrosulfur-based c...

Embodiment 3

[0040] Example 3: 7% dinotefuran · thiazolysin fertilizer granules (1.5:5.5)

[0041] The medicinal fertilizer granule formulation of the present embodiment consists of: 15.8 kg of dinotefuran technical material with 95% active ingredient content, 64.7 kg of thiazophosphine technical material with 85% active component content, 22 kg of white carbon black, and 25 kg of oily coke powder , potassium humate 5kg, urea 100kg, diammonium phosphate 767.5kg.

[0042] The specific preparation process steps of Yaofei Granules are:

[0043] ①Using 22kg of white carbon black, 64.7kg of thiazophosphine with an active ingredient content of 85% was fully adsorbed in a double-helix stirred tank, and then 15.8kg of dinotefuran with an active ingredient content of 95% was put into the double-helix stirring tank. In the spiral stirring tank, after fully mixing evenly, pass through a jet mill to prepare a 200-300-mesh powder combination for later use.

[0044] ② Mix 100kg of urea, 767.5kg of dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com