PVB (polyvinyl butyral) paste containing tungsten bronze and its preparing method

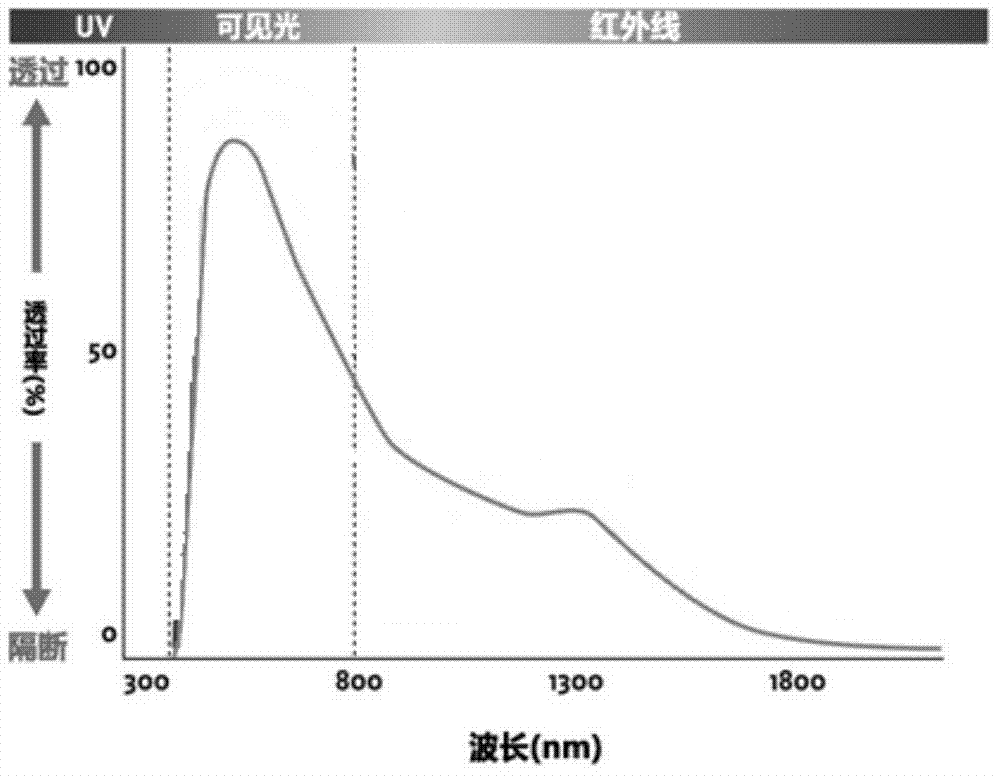

A technology of tungsten bronze and slurry, applied in the field of polymers, can solve the problems of easy separation of heat insulating particles, no barrier to heat conduction, and unsatisfactory heat insulation performance of PVB film, so as to improve texture, color saturation and service life Long-lasting, long-lasting thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Containing the PVB slurry of tungsten bronze, its raw material comprises following components: 40 parts of tungsten bronze particles, 5 parts of polyvinyl alcohol phenolic resin (model, PF301, Huantai Yonghui Chemical Co., Ltd.), plasticizer (diethylene diethylene glycol) Alcohol dibenzoate vitriol, DEDB) 55 parts, 1.5 parts of sodium dioctyl succinate sulfonate, 2.5 parts of hexenyl bis stearamide and 0.9 parts of isopropyl triisostearyl titanate, the number of parts is parts by mass.

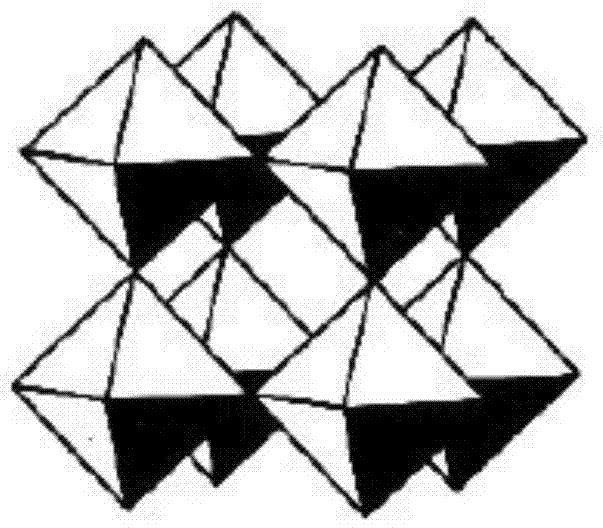

[0032] The structural formula of tungsten bronze is M0.WO 3 , wherein, M0 is sodium oxide, and the molar ratio of sodium oxide to tungsten trioxide is 1:1; the acetylation degree of the above-mentioned PVB slurry containing tungsten bronze is 9 mol%.

[0033] The preparation method of PVB slurry containing tungsten bronze is: mix and grind tungsten bronze particles, plasticizer, surfactant, dispersant and coupling agent for 3 hours in a horizontal bead mill (0.1mm zirconia beads) Fina...

Embodiment 2

[0035] Containing the PVB slurry of tungsten bronze, its raw material comprises the following components: 35 parts of tungsten bronze, 3 parts of polyvinyl alcohol phenolic resin (model, PF301, Huantai County Yonghui Chemical Co., Ltd.), plasticizer (butylene diester, DBP, Jinan Hengrui Chemical Co., Ltd.) 50 parts, 1 part of sodium dodecylbenzenesulfonate, 2 parts of hexenyl bisstearamide and 0.8 part of isopropyl triisostearyl titanate, the number of parts is the number of parts by mass.

[0036] The structural formula of tungsten bronze is M0.WO 3 , wherein, M0 is cesium oxide, and the molar ratio of cesium oxide to tungsten trioxide is 1:1; the acetylation degree of the above-mentioned PVB slurry containing tungsten bronze is 0.4 mol%.

[0037] The preparation method of PVB slurry containing tungsten bronze is: mix and grind tungsten bronze particles, plasticizer, surfactant, dispersant and coupling agent for 3 hours in a horizontal bead mill (0.1mm zirconia beads) Final...

Embodiment 3

[0039] Containing the PVB slurry of tungsten bronze, its raw material comprises following components: 45 parts of tungsten bronze, ethylene-acrylic acid copolymer resin (pure resin powder EEA, melt flow rate, 190 ℃ / 2.16kg) 7 parts, plasticizer ( Diethylene glycol dibenzoate alum, DEDB) 60 parts, sodium lauryl sulfate 2 parts, carboxylate polymer (model, EL-2311, Dongguan Yili'an Chemical Technology Co., Ltd.) 3 parts and γ- 1 part of methacryloxypropyltrimethoxysilane, the said parts are parts by mass.

[0040] The structural formula of tungsten bronze is M0.WO 3 , wherein, M0 is magnesium oxide and sodium oxide, the molar ratio of magnesium oxide and sodium oxide is 1:1, and the molar ratio of the sum of magnesium oxide and sodium oxide to tungsten trioxide is 1:1; the above-mentioned PVB containing tungsten bronze The degree of acetylation of the slurry was 18 mol%.

[0041] The preparation method of PVB slurry containing tungsten bronze is: mix and grind tungsten bronze par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com