Preparation method of titanous auto-doping anatase titanium dioxide monocrystalline

A technology of titanium dioxide and trivalent titanium, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve problems such as difficult to obtain form distribution, expensive equipment, harsh synthesis conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

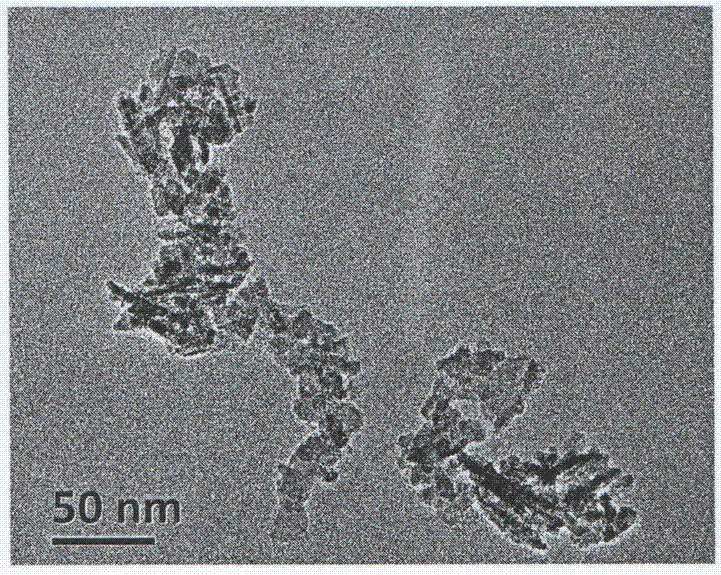

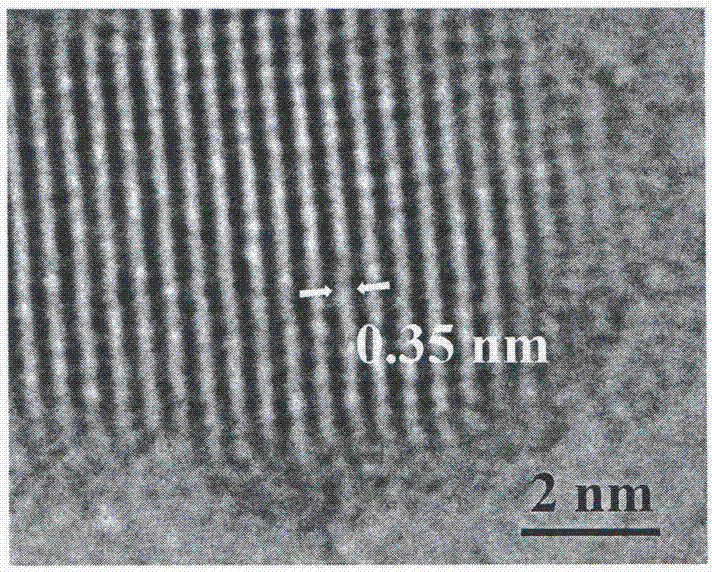

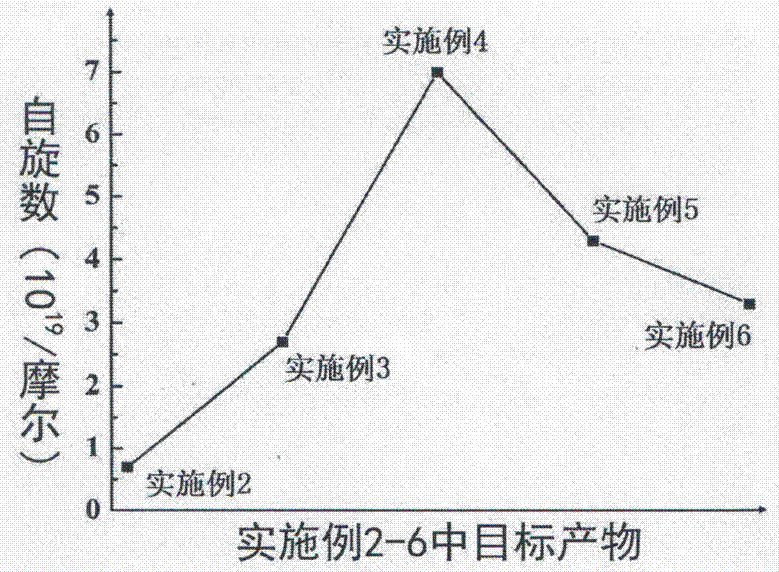

Image

Examples

Embodiment 1

[0018] a. Dissolve 0.3g of divalent titanium source titanium hydride in 2mL of deionized water, add 30mL of hydrogen peroxide with a mass fraction of 30% dropwise under constant stirring, and keep stirring the mixed reaction solution rapidly at room temperature for 12h to obtain a gel-like shape mixture;

[0019] b. Under uniform stirring, add 40 mL of absolute ethanol to the mixture obtained in step a, adjust the pH of the mixed solution to 8 with 1.0 M sodium hydroxide solution, then add 0.4 g of sodium borohydride to obtain a transparent yellow mixed solution;

[0020] c. Place the mixed solution obtained in step b in an autoclave at a temperature of 180° C. and react for 24 hours;

[0021] d. Remove the mixed solution obtained in step c from the autoclave, wash it in 50.0mL of 1.0M hydrochloric acid solution for 10h, and then centrifuge to obtain the precipitate, wash it twice with absolute ethanol, wash it three times with deionized water, and place it in Dry in a vacuum...

Embodiment 2

[0024] a. Dissolve 0.3g of divalent titanium source titanium hydride in 2mL of deionized water, add 30mL of hydrogen peroxide with a mass fraction of 30% dropwise under constant stirring, and keep stirring the mixed reaction solution rapidly at room temperature for 12h to obtain a gel-like shape mixture;

[0025] b. Under uniform stirring, add 40 mL of absolute ethanol to the mixture obtained in step a, adjust the pH of the mixed solution to 9 with 1.0 M sodium hydroxide solution, then add 0.4 g of sodium borohydride to obtain a transparent yellow mixed solution;

[0026] c. Place the mixed solution obtained in step b in an autoclave at a temperature of 180° C. and react for 24 hours;

[0027] d. Remove the mixed solution obtained in step c from the autoclave, wash it in 50.0mL of 1.0M hydrochloric acid solution for 10h, and then centrifuge to obtain the precipitate, wash it twice with absolute ethanol, wash it three times with deionized water, and place it in Dry in a vacuum...

Embodiment 3

[0030] a. Dissolve 0.3g of divalent titanium source titanium hydride in 2mL of deionized water, add 30mL of hydrogen peroxide with a mass fraction of 30% dropwise under constant stirring, and keep stirring the mixed reaction solution rapidly at room temperature for 12h to obtain a gel-like shape mixture;

[0031] b. Under uniform stirring, add 40 mL of absolute ethanol to the mixture obtained in step a, adjust the pH of the mixed solution to 9 with 1.0 M sodium hydroxide solution, then add 0.4 g of sodium borohydride to obtain a transparent yellow mixed solution;

[0032] c. Place the mixed solution obtained in step b in an autoclave at a temperature of 180° C. and react for 24 hours;

[0033] d. Remove the mixed solution obtained in step c from the autoclave, wash it in 50.0mL of 1.0M hydrochloric acid solution for 10h, and then centrifuge to obtain the precipitate, wash it twice with absolute ethanol, wash it three times with deionized water, and place it in Dry in a vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com