A method for preparing dual stimuli-responsive surfaces by secondary photopolymerization

A stimuli-responsive, secondary light technology, applied in the field of preparing dual stimuli-responsive surfaces through secondary photopolymerization, can solve the problems of easy shedding of surface compounds, easy aging of polymers, complicated reaction process, etc., and achieve good photoresponse performance. , good pH response performance, strong grafting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: surface modification of quartz sheet

[0049] (1), silanization of quartz sheet: immerse the quartz sheet successively in ethanol, acetone, and deionized water for ultrasonic treatment for 5 minutes, blow dry with nitrogen, and put into "piranha" solution [concentrated sulfuric acid (98%wt.%) and hydrogen peroxide (30%wt.%) heated in a volume ratio of 7:3] for 2 hours, then rinsed with a large amount of deionized water, and dried with nitrogen to make the surface rich in hydroxylation. Take 10 mg of γ-methacryloxypropyltrimethoxysilane (γ-MPS) and add it to 10 mL of toluene solution, and immerse the hydroxylated quartz plate in it for 12 hours. Due to hydrolytic condensation, the surface of the quartz plate will be grafted A silane coupling agent with a double bond; wash the substrate grafted with the silane coupling agent with ethanol, and dry it with nitrogen gas for later use.

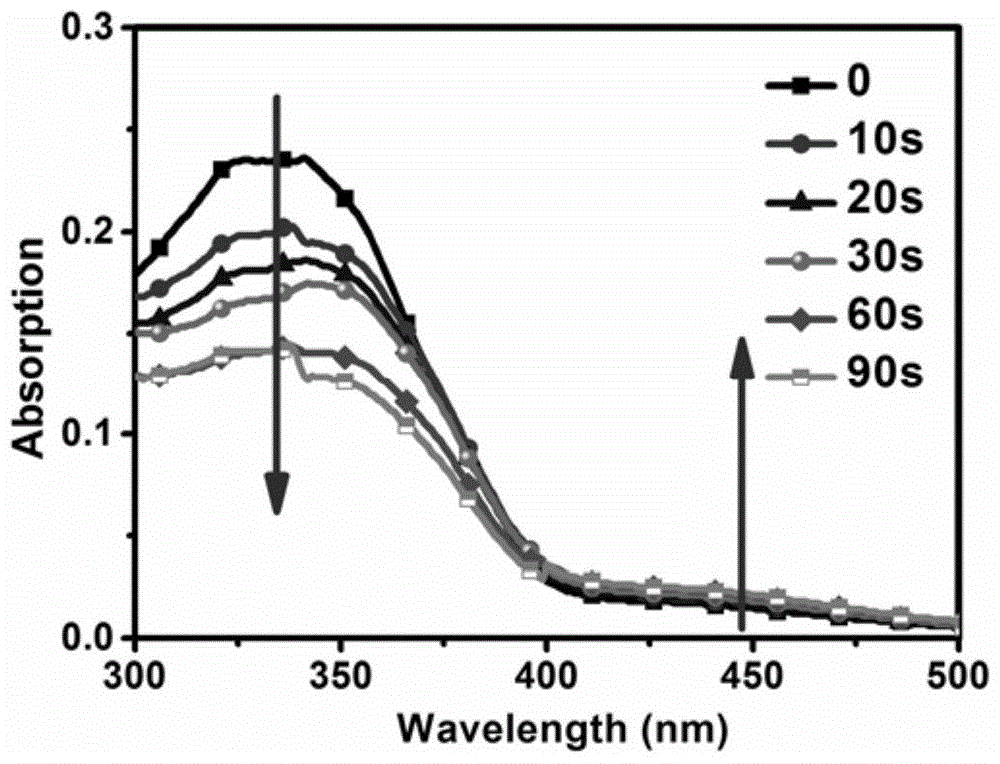

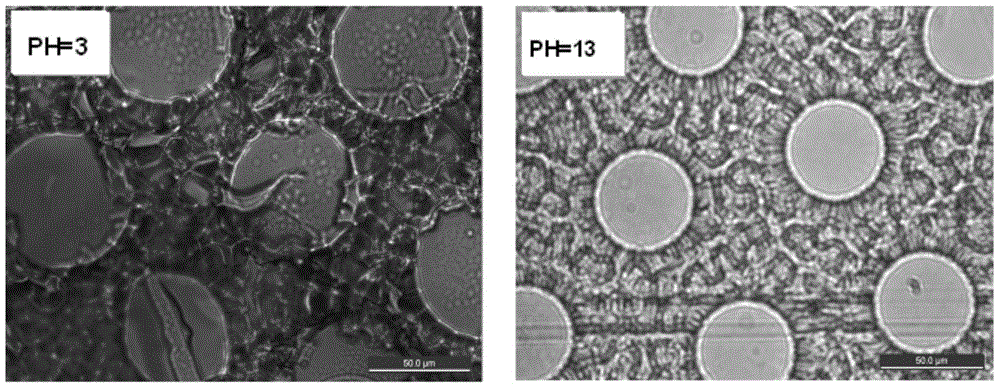

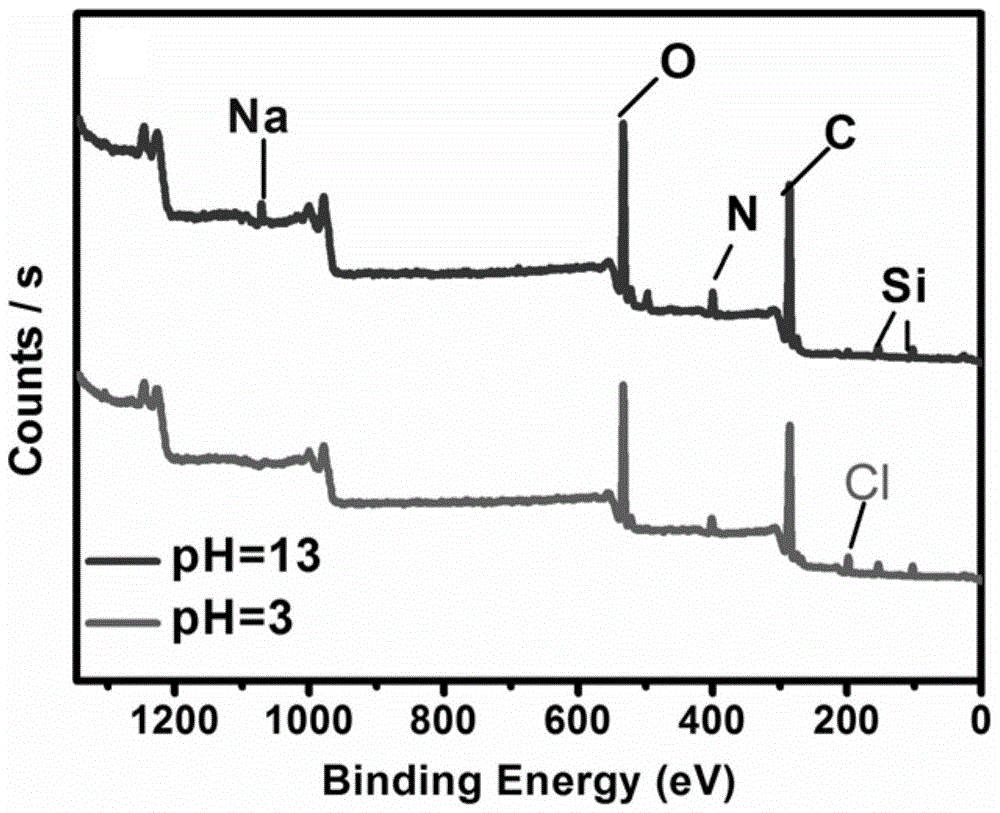

[0050] (2), preparation of pH-responsive photopolymerization system soluti...

Embodiment 2

[0053] Embodiment 2: surface modification of glass sheet

[0054] (1), glass sheet silanization: the glass sheet is immersed in ethanol, acetone, deionized water and ultrasonically cleaned for 5 minutes, blown dry with nitrogen, and put into "piranha" solution [concentrated sulfuric acid (98%wt.%) and hydrogen peroxide (30%wt.%) heated in a volume ratio of 7:3] for 2 hours, then rinsed with a large amount of deionized water, and dried with nitrogen for later use. Take 10mg of γ-methacryloxypropyltrimethoxysilane (γ-MPS) and add it to 10mL of toluene solution, immerse the hydroxylated glass sheet in it for 12 hours, and graft the silane coupling agent with double bond on the surface of the glass sheet ; Clean the glass piece grafted with silane coupling agent with ethanol, and dry it with nitrogen gas for later use.

[0055] (2), prepare the photopolymerization system solution (DMAEMA-80wt.%, ethanol 9.9wt.%,-photoinitiator 2-hydroxyl-2 methyl-1-phenyl ketone-0.1wt.% of cross-...

Embodiment 3

[0059] Embodiment 3: silicon wafer surface modification

[0060] (1), silicon wafer surface silanization: the silicon wafer is successively immersed in ethanol, acetone, deionized water and ultrasonically cleaned for 5 minutes, blown dry with nitrogen, and put into "piranha" solution [concentrated sulfuric acid (98%wt.%) and Hydrogen peroxide (30%wt.%) was heated in a volume ratio of 7:3] for 4 hours, then rinsed with a large amount of deionized water, and dried with nitrogen gas for later use. Take 10mg of γ-methacryloxypropyltrimethoxysilane (γ-MPS) and add it to 10mL of toluene solution, immerse the hydroxylated silicon chip in it for 12 hours, and graft the silane coupling agent with double bond on the surface of the silicon chip ; Clean the silicon chip grafted with silane coupling agent with ethanol, and dry it with nitrogen gas for later use.

[0061] (2), prepare pH-responsive photopolymerization system solution (DMAEMA-20wt.%, ethanol 74wt.%, -photoinitiator 2-hydrox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com