Complete compound feed for boar and preparation method thereof

A technology for compound feed and boars, which is applied in the field of animal husbandry, can solve problems such as inability to relieve heat stress of boars, and achieve the effects of improving the body's ability to resist heat stress, reducing pollution and reducing excretion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the above-mentioned high-efficiency and environment-friendly full-price compound feed for boars has the following steps:

[0037] Step 1: Raw material receiving and cleaning

[0038]Various raw materials in bags or in bulk are measured and discharged into the discharge pit respectively. After passing through the scraper conveyor and bucket elevator, they enter the initial cleaning screen of the cylinder. After dust removal and impurities removal, they enter the permanent magnet cylinder to remove iron impurities. .

[0039] The second step: raw material crushing

[0040] Various raw materials enter the sieve plate of the pulverizer with different specifications for pulverization.

[0041] Step 3: Ingredients

[0042] Big and small batching weighs the weight percentage of each raw material and accurately batches; batching accuracy: static 1 / 1000F.S; dynamic and static 3 / 1000F.S.

[0043] Step 4: Mixing of ingredients

[0044] Materials such...

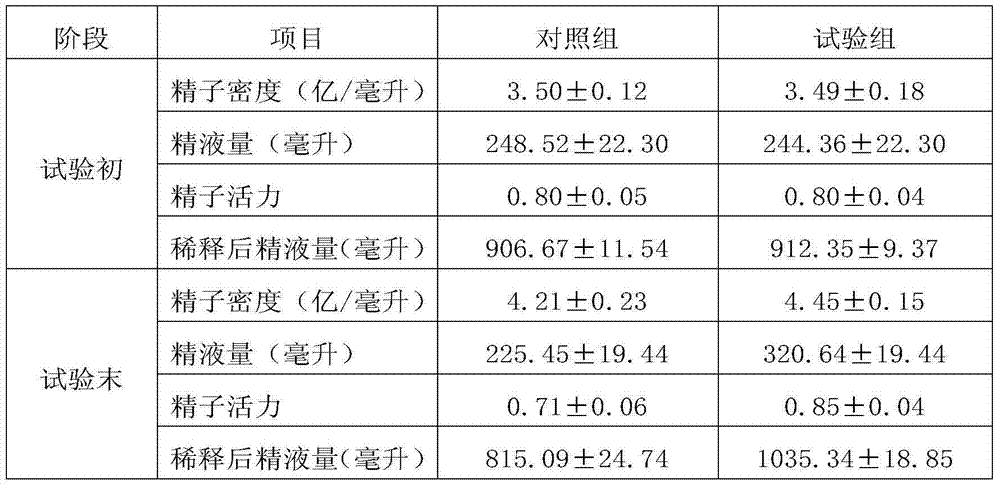

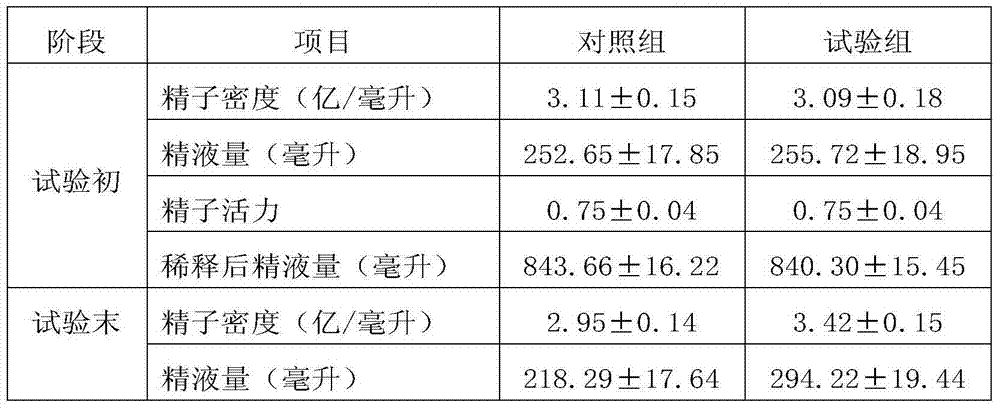

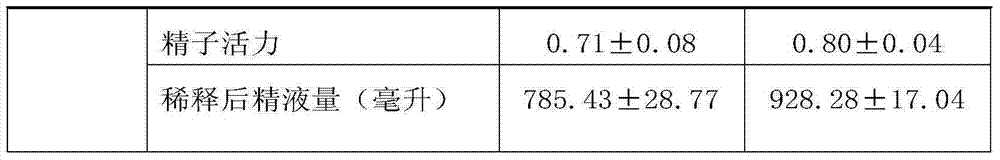

Embodiment 1

[0051] The product is formulated in the following percentages by weight: corn 52.6%, dehulled soybean meal 12%, wheat 15%, soybean hulls 7%, wheat bran 5%, fermented soybean meal 1.7%, fish meal 2%, calcium hydrogen phosphate 1.7%, stone powder 1.2% , lysine 0.45%, methionine 0.05%, threonine 0.10%, compound enzyme preparation 0.02%, probiotics 0.08%, sodium bicarbonate 0.2%, arginine generator 0.1%, sodium chloride 0.3%, public 0.5% compound premix for pigs.

[0052] The compound enzyme preparation is a mixture of cellulase and β-glucanase; the microecological preparation is a mixture of Enterococcus faecalis and Lactobacillus acidophilus; the compound premix is vitamin A, E, D3, K3, B1, B2, A mixture of B6, folic acid, pantothenic acid, niacin, trace elements copper, iron, manganese, organic zinc, iodine, organic selenium and carriers.

Embodiment 2

[0054] The product is formulated in the following percentages by weight: corn 54.4%, dehulled soybean meal 12%, wheat 13%, soybean hulls 10%, wheat bran 3%, fermented soybean meal 1%, fish meal 1%, calcium hydrogen phosphate 1.8%, stone powder 1.4% , lysine 0.45%, methionine 0.05%, threonine 0.1%, compound enzyme preparation 0.01%, probiotics 0.09%, sodium bicarbonate 0.2%, arginine generator 0.2%, sodium chloride 0.3%, public 1% compound premix for pigs.

[0055] The compound enzyme preparation is a mixture of cellulase and xylanase; the microecological preparation is a mixture of Enterococcus faecalis and Lactobacillus acidophilus; the compound premix is vitamin A, E, D3, K3, B1, B2, B6, Blend of folic acid, pantothenic acid, niacin, trace elements copper, iron, manganese, organic zinc, iodine, organic selenium and carriers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com