Comprehensive utilization method of cumin and prepared product

A technology of cumin and cumin essential oil, applied in the field of comprehensive utilization of cumin, can solve problems such as unfavorable farmers' income creation and value creation, single product form, waste of resources and environment, etc., achieve structural adjustment and industrialization development promotion, and enrich market products. , the effect of inhibiting oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

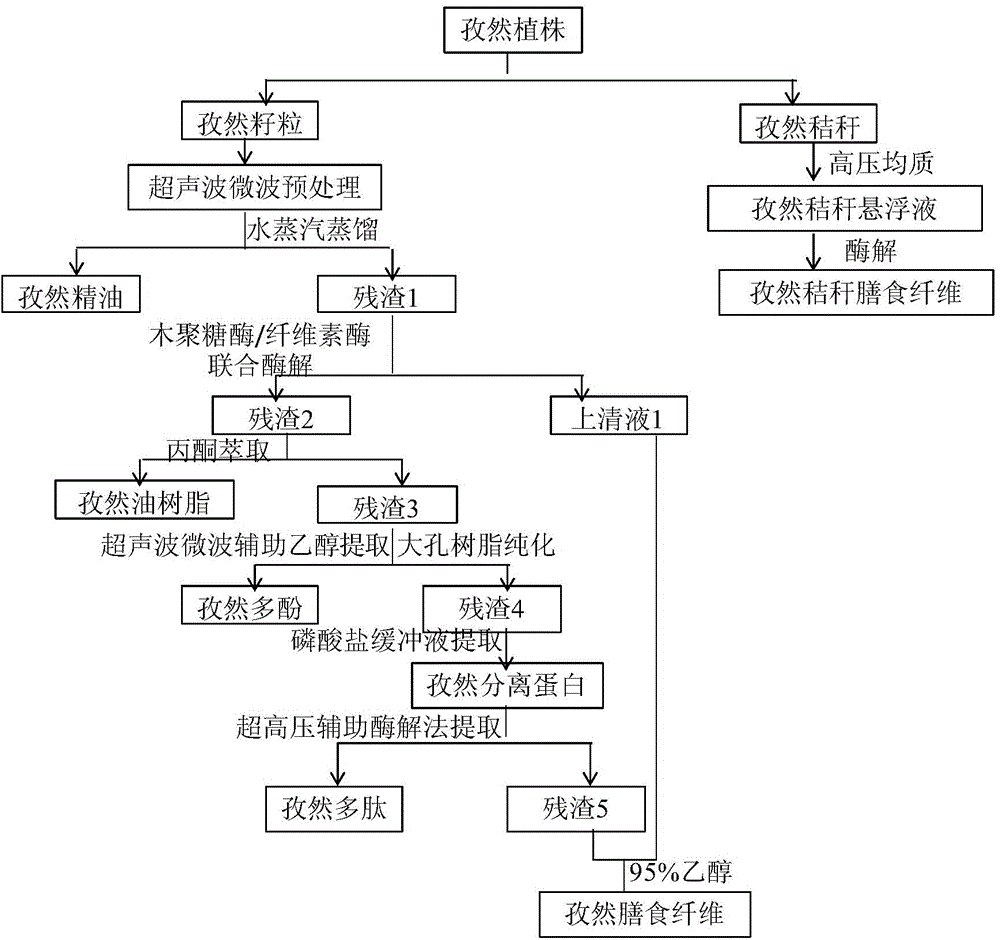

Method used

Image

Examples

Embodiment 1

[0049] The extraction of embodiment 1, cumin essential oil

[0050] The harvested cumin is air-selected to remove impurities to obtain cumin seeds with a purity ≥ 98%, then mix the cumin seeds with water at a ratio of 1:5g / mL, and put them into an ultrasonic microwave extractor. 35kHz, microwave power 45W pretreatment 25min; then transfer the cumin seeds treated by ultrasonic microwave to the distillation basket of the essential oil extraction unit (manufacturer: Shanghai Juyuan Machinery Equipment Co., Ltd., model: JYT5L), add water to the distillation tank , the height of the water does not exceed the distillation basket, and it is extracted by steam distillation. Set the temperature in the extraction tank to 100°C, and the extraction time to 30min. The obtained oil is collected and packaged to obtain cumin essential oil. Appearance see Figure 4 Of (a).

Embodiment 2

[0051] Embodiment 2, the extraction of cumin oleoresin

[0052] Dry the remaining cumin grain residue after extracting the essential oil in Example 1 with an oven at 50° C. to make its moisture content reach about 8%, pulverize it with a universal pulverizer until the particle size is less than 400 μm, and take the pulverized powder and pH The sodium acetate buffer solution of 4.5 was mixed and shaken at a ratio of 1:10g / mL, and 3.5% mixed enzyme solution of xylanase and cellulase was added according to the concentration ratio of enzyme and substrate (xylanase: cellulase=1 : 1), enzymolysis at 50°C for 120min, centrifugation at 7500g for 20min, the resulting precipitate was used to extract cumin oleoresin, and the supernatant was preserved for future use.

Embodiment 3

[0054] Embodiment 3, the preparation of cumin polyphenol crude extract

[0055] Get embodiment 2 and add acetone and centrifuge the residue obtained after drying at 50°C and pulverize with a universal pulverizer, cross a 40-mesh sieve (the precipitation will agglomerate after drying, so it will be pulverized and sieved), and the cumin residue after the sieve Mix the powder with 70% ethanol at a ratio of 1:10g / mL, put it into an ultrasonic microwave-assisted extractor, set the ultrasonic vibration frequency to 51kHz, and microwave power to 130W. After extraction for 10 minutes, centrifuge at 7500g for 20 minutes to collect the supernatant; then The precipitate was repeatedly extracted twice by the above method, and the three times of extracts were combined, and the ethanol was removed by rotary evaporation at 45°C to obtain the crude cumin polyphenol extract. (The remaining precipitate was extracted for Example 5).

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com