Method for extracting water-insoluble collagen from thoracic aorta of pig

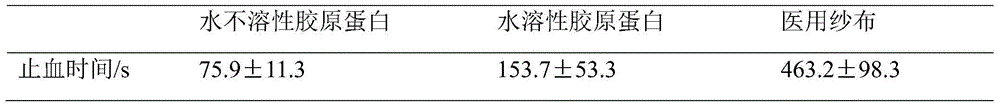

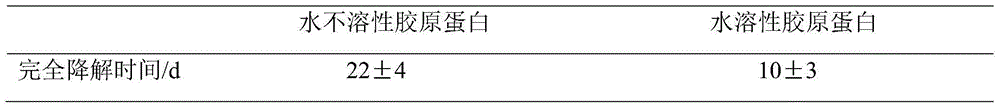

A technology of collagen and thoracic aorta, which is applied in the field of preparing water-insoluble collagen, can solve the problems of not being better utilized, reducing the safety of collagen materials, and destroying collagen components, so as to achieve good biological activity and no toxic side effects , the effect of reducing the degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A method for extracting water-insoluble collagen from pig thoracic aorta, comprising the steps of:

[0017] (1) Pretreatment: adopt quarantine-qualified pigs, open the cavity aseptically, take the thoracic aorta, remove the surface connective tissue, rinse with sterile water, freeze-dry, and pulverize to 100 mesh;

[0018] (2) Degreasing: Place the crushed thoracic aorta in step (1) in acetone reagent, stir at -20°C for 12 hours, centrifuge at 5000r / min for 30 minutes, remove the milky white supernatant, and replace it with a new one. Acetone reagent Repeat the above degreasing operation until the supernatant is clear and transparent, remove the supernatant, and place the lower product in a vacuum drying oven to air dry;

[0019] (3) Impurity removal: Add 4M guanidine hydrochloride solution 10 times the volume of the product weight to the lower layer product obtained in step (2), stir at 4°C for 72 hours, centrifuge at 8000r / min for 30min, and remove the supernatant Af...

Embodiment 2

[0026] A method for extracting water-insoluble collagen from pig thoracic aorta, comprising the steps of:

[0027] (1) Pretreatment: adopt quarantine-qualified pigs, open the cavity aseptically, take the thoracic aorta, remove the surface connective tissue, rinse with sterile water, freeze-dry, and pulverize to 70 mesh;

[0028] (2) Degreasing: Place the crushed thoracic aorta in step (1) in acetone reagent, stir at -20°C for 12 hours, centrifuge at 5000r / min for 30 minutes, remove the milky white supernatant, and replace it with a new one. Acetone reagent Repeat the above degreasing operation until the supernatant is clear and transparent, remove the supernatant, and place the lower product in a vacuum drying oven to air dry;

[0029] (3) Impurity removal: Add 4M guanidine hydrochloride solution of 12 times the volume of the product weight to the lower layer product obtained in step (2), stir at 4°C for 72 hours, centrifuge at 8000r / min for 30min, and remove the supernatant ...

Embodiment 3

[0036] A method for extracting water-insoluble collagen from pig thoracic aorta, comprising the steps of:

[0037] (1) Pretreatment: adopt quarantine-qualified pigs, open the cavity aseptically, take the thoracic aorta, remove the surface connective tissue, rinse with sterile water, freeze-dry, and pulverize to 30 mesh;

[0038] (2) Degreasing: Place the crushed thoracic aorta in step (1) in acetone reagent, stir at -20°C for 12 hours, centrifuge at 5000r / min for 30 minutes, remove the milky white supernatant, and replace it with a new one. Acetone reagent Repeat the above degreasing operation until the supernatant is clear and transparent, remove the supernatant, and place the lower product in a vacuum drying oven to air dry;

[0039] (3) Impurity removal: Add 4M guanidine hydrochloride solution 15 times the volume of the product weight to the lower layer product obtained in step (2), stir at 4°C for 72 hours, centrifuge at 8000r / min for 30min, and remove the supernatant Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com