Method for preparing vanadium dioxide low-temperature thermochromic film

A technology of vanadium dioxide and color-changing thin film, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problem of high phase transition temperature, small adjustment range of infrared light, and no visible light transmittance And infrared light adjustment range and other issues, to achieve the effect of reducing the phase transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

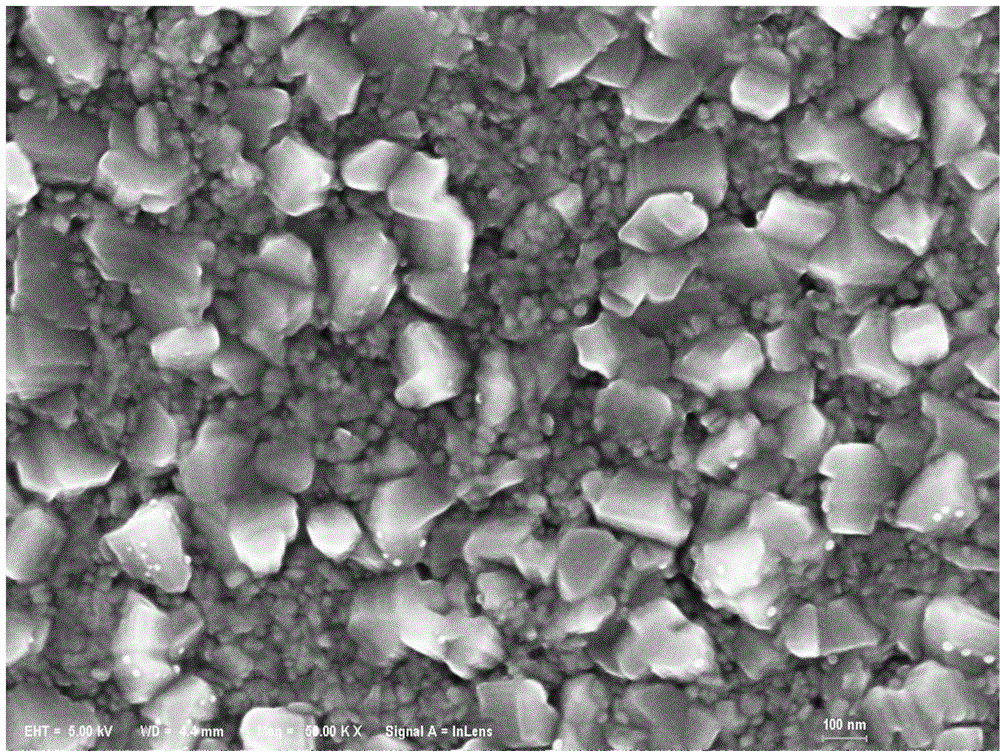

[0033] Using DC reactive magnetron sputtering technology, high-purity metal vanadium is used as the target material, glass is used as the substrate, high-purity oxygen and argon are used as the reaction gas and sputtering gas, and the background vacuum is pumped to 1-3x10 -4 Pa, then feed a certain amount of oxygen and argon, so that the oxygen partial pressure is 10%, the working pressure is 1.0Pa, the substrate temperature is room temperature, and a 100nm thick vanadium pentoxide film is grown, and then the temperature is raised to 400°C. The oxygen / argon gas is 45%, the working pressure is 0.8Pa, and high-purity metal titanium is used as the target material to induce sputtering growth of 150nm rutile titanium dioxide film. Through a solid-liquid reaction mechanism, the substrate / rutile titanium dioxide / vanadium pentoxide structure was realized, followed by annealing at 400 °C for 1 hour in a reducing atmosphere. The SEM images of the obtained samples are shown in figure 1 ...

Embodiment 2

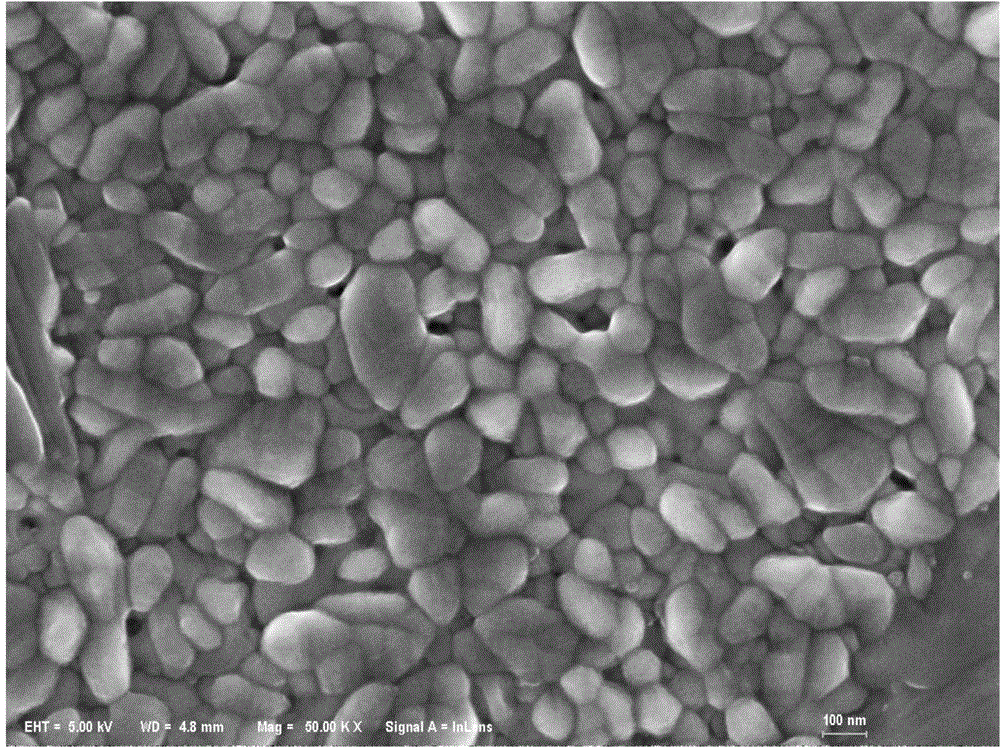

[0035] Using DC reactive magnetron sputtering technology, high-purity metal vanadium is used as the target material, glass is used as the substrate, high-purity oxygen and argon are used as the reaction gas and sputtering gas, and the background vacuum is pumped to 1-3x10 -4 Pa, feed a certain amount of oxygen gas and argon gas then, the oxygen / argon gas flow ratio that makes is 30%, working pressure is 1.0Pa, and substrate temperature is room temperature, grows the thick vanadium pentoxide thin film of 120nm, then heats up to 400°C, oxygen / argon 40%, working pressure 0.2Pa, high-purity titanium metal as target, power density 4.5W / cm2, induced sputtering growth rutile titanium dioxide film 150nm. Through a solid-liquid reaction mechanism, the substrate / rutile titania / vanadium pentoxide structure is realized, and then the N 2 Anneal at 700°C for 1 hour in an inert environment. The SEM images of the obtained samples are shown in figure 2 As shown, the phase transition tempera...

Embodiment 3

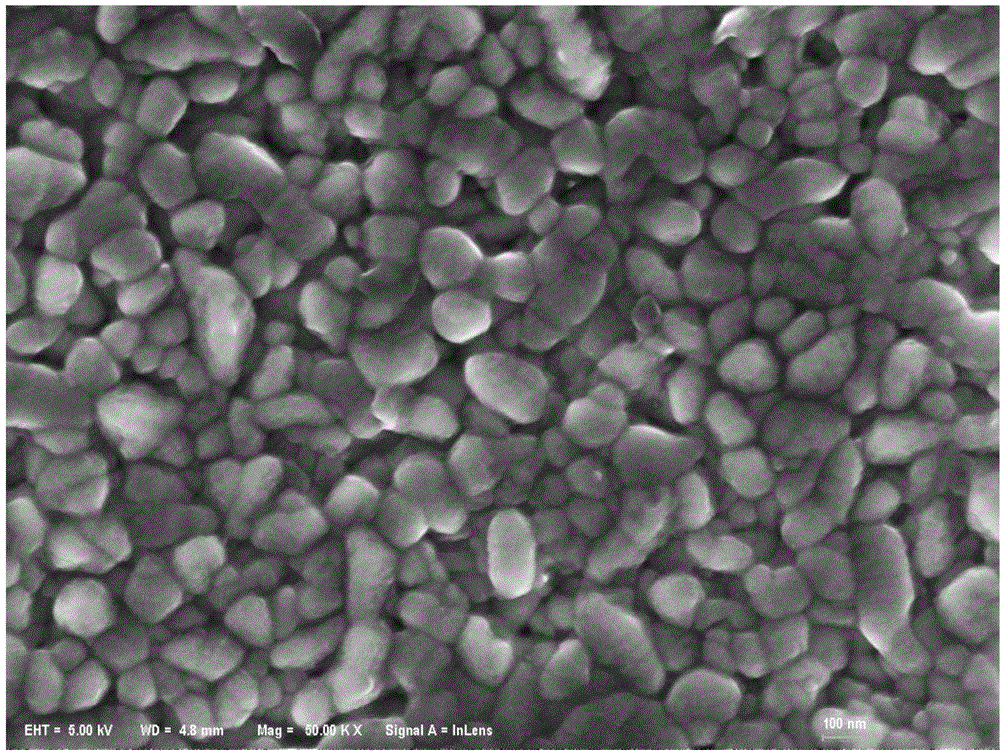

[0037] Using DC reactive magnetron sputtering technology, high-purity metal vanadium is used as the target material, glass is used as the substrate, high-purity oxygen and argon are used as the reaction gas and sputtering gas, and the background vacuum is pumped to 1-3x 10 -4Pa, then feed a certain amount of oxygen and argon, so that the oxygen / argon flow ratio is 20%, the working pressure is 0.5Pa, the substrate temperature is 200°C, grow a 100nm thick vanadium pentoxide film, and then heat up To 400°C, the oxygen / argon gas is 12%, the working pressure is 0.2Pa, high-purity metal titanium is used as the target, the power density is 5W / cm2, and the rutile titanium dioxide film is grown by sputtering to 150nm. Through a solid-liquid reaction mechanism, the substrate / rutile titanium dioxide / vanadium pentoxide structure was realized, followed by annealing at 400 °C for 1 hour in a reducing atmosphere. The phase transition temperature of the vanadium dioxide thin film is 38°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com