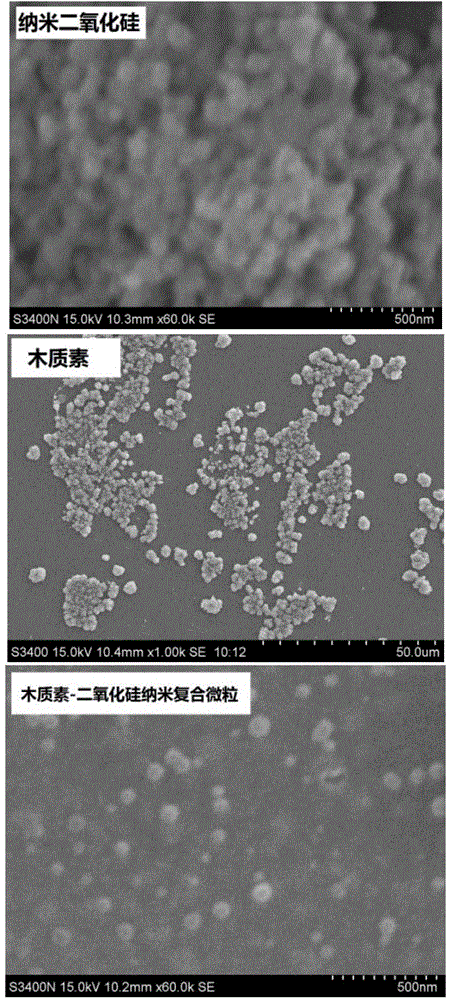

Lignin-silicon dioxide nanocomposite particle as well as preparation method and application of lignin-silicon dioxide nanocomposite particle

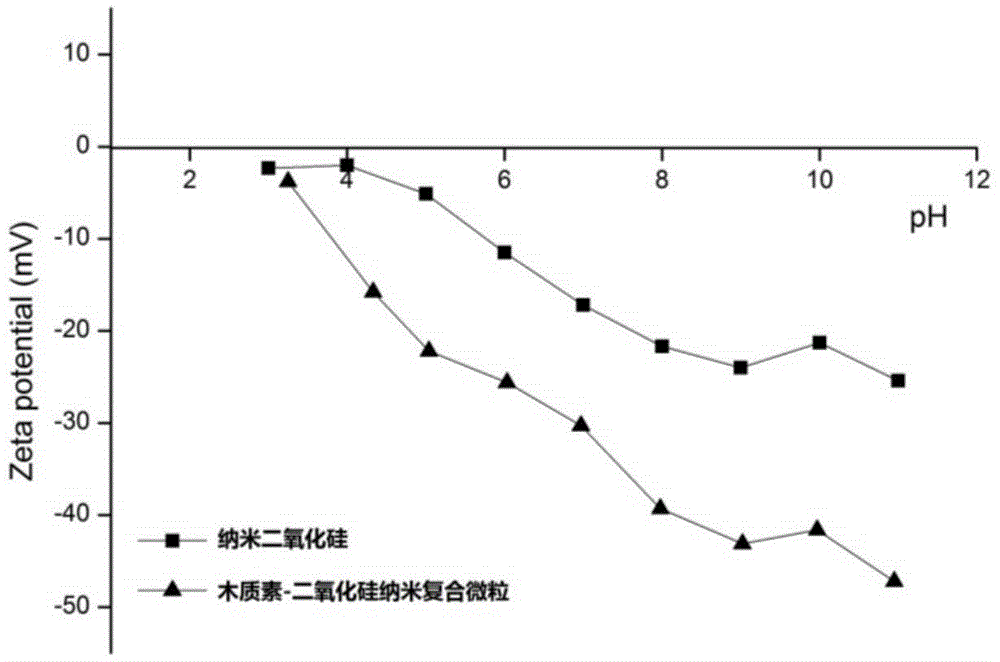

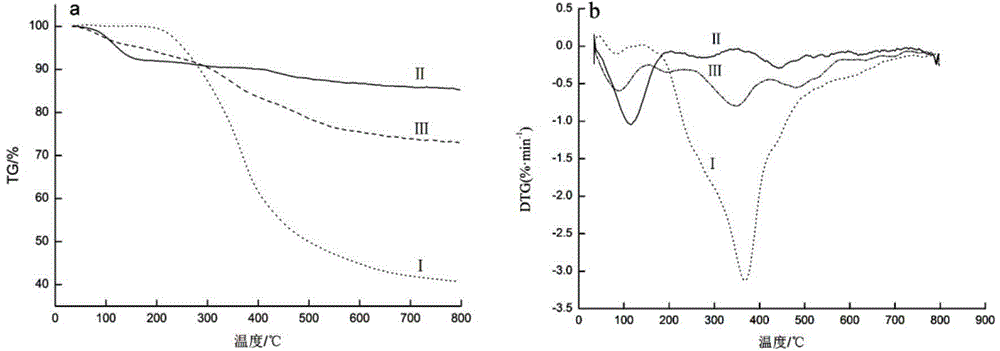

A silicon dioxide and nanocomposite technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of poor compatibility, complex composition, difficult chemical modification, etc., achieve excellent selective adsorption performance of heavy metal ions, improve Dispersibility and thermal stability, overcoming difficult processing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Preparation of bromine-based nano-silica

[0036] Put 1.0g of nano-silica and 60mL of toluene in a round bottom flask, add 0.5mL of 3-bromopropyltrichlorosilane dropwise, and react at 80°C for 24h. After static filtration, the white filter cake was washed with toluene and absolute ethanol to remove excess 3-bromopropyltrichlorosilane, and after freeze-drying, a white solid bromine-based nano-silica was obtained.

[0037] (2) Preparation of azide-based nano-silica

[0038] Add 0.6g of bromo-based nano-silica, 0.4g of sodium azide and 160mL of N,N-dimethylformamide solution into a 250mL three-necked flask, heat to 80°C, and react under nitrogen atmosphere for 24h. The reaction solution was centrifuged for 3 times, filtered to obtain a crude product, and freeze-dried to obtain a white powder product azido-based nano-silicon dioxide.

[0039] (3) Preparation of alkynyl lignin

[0040] Dissolve 4.0g of bamboo lignin in 80mL of 0.5mol / L sodium hydroxide solution, add 4...

Embodiment 2

[0045] (1) Preparation of bromine-based nano-silica

[0046] Put 2.0g of nano-silica and 60mL of toluene in a round bottom flask, add 0.5mL of 11-bromoundecyltrichlorosilane dropwise, and react at 90°C for 24h. After static filtration, the white filter cake was washed with toluene and absolute ethanol to remove excess 11-bromoundecyltrichlorosilane, and after freeze-drying, a white solid bromine-based nano-silica was obtained.

[0047] (2) Preparation of azide-based nano-silica

[0048] Add 0.8g of bromo-based nano-silica, 0.8g of sodium azide and 150mL of N,N-dimethylformamide solution into a 250mL three-necked flask, heat to 80°C, and react under nitrogen atmosphere for 24h. The reaction solution was filtered through a G-4 type sand core funnel to obtain a crude product, which was freeze-dried to obtain a white powder product azido-based nano-silicon dioxide.

[0049] (3) Preparation of alkynyl lignin

[0050] Dissolve 5.0g of alkali lignin in 80mL of 0.5mol / L sodium hydr...

Embodiment 3

[0056] (1) Preparation of chlorine-based nano-silica

[0057] Put 1.5g of nano-silica and 60mL of toluene into a round bottom flask, add 0.5mL of 3-chloropropyltrichlorosilane dropwise, and react at 90°C for 24h. After static filtration, the white filter cake was washed with toluene and absolute ethanol to remove excess 3-chloropropyltrichlorosilane, and after freeze-drying, a white solid bromine-based nano-silica was obtained.

[0058] (2) Preparation of azide-based nano-silica

[0059] Add 0.7g of chlorine-based nano-silica, 0.8g of sodium azide and 150mL of N,N-dimethylformamide solution into a 250mL three-necked flask, heat to 80°C, and react under nitrogen atmosphere for 24h. The reaction solution was filtered through a G-4 type sand core funnel to obtain a crude product, which was freeze-dried to obtain a white powder product azido-based nano-silicon dioxide.

[0060] (3) Preparation of alkynyl lignin

[0061] Dissolve 5.0g high boiling alcohol lignin in 80mL sodium h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com