Copper/indium/gallium rotating target and method for preparing copper/indium/gallium rotating target by controllable atmosphere cold spraying

A copper indium gallium and rotating target technology, which is applied in metal material coating process, coating, ion implantation plating, etc., can solve the problems of increasing target production cost, target off-target, arcing, etc., to reduce oxygen and Intervention of impurities, uniform coating composition without segregation, and compact coating structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

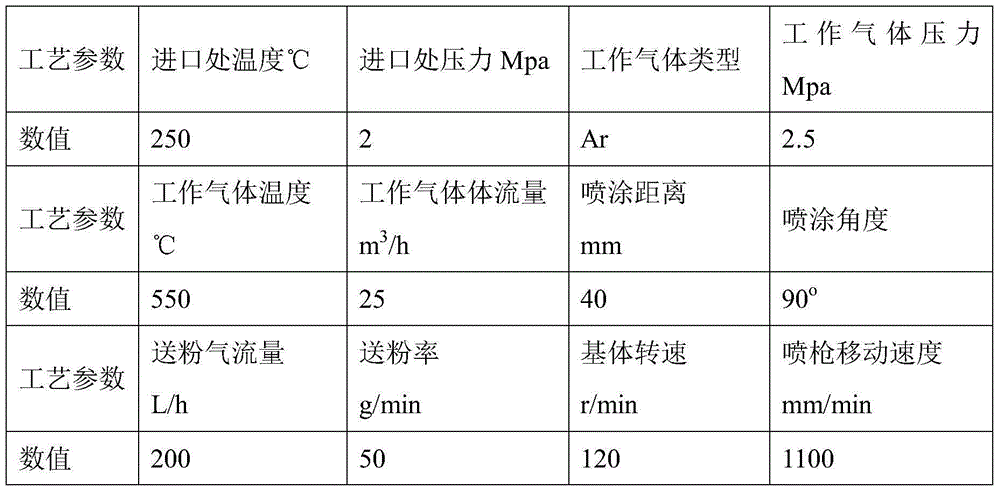

Embodiment 1

[0025] A method for preparing a copper indium gallium rotating target by controlled atmosphere cold spraying, comprising the following steps:

[0026] (1) Ultrasonic cleaning of the stainless steel substrate for 30 minutes, then drying and sandblasting, the sandblasting sand particles are brown corundum, and the particle size is 18 mesh;

[0027] (2) In an argon gas protective atmosphere, use a plasma spraying process to spray nickel-aluminum powder, and prepare a primer layer with a thickness of 0.1mm on the stainless steel substrate after sandblasting;

[0028] (3) In an argon gas protective atmosphere, use a plasma spraying process to spray copper indium powder, and prepare a transition layer with a thickness of 0.1mm on the stainless steel substrate sprayed with a primer layer;

[0029] (4) Use copper indium gallium powder with a D50 of 100 microns and a purity of not less than 99.99% as raw material, put the raw material into a planetary ball mill and grind it for 5 hours...

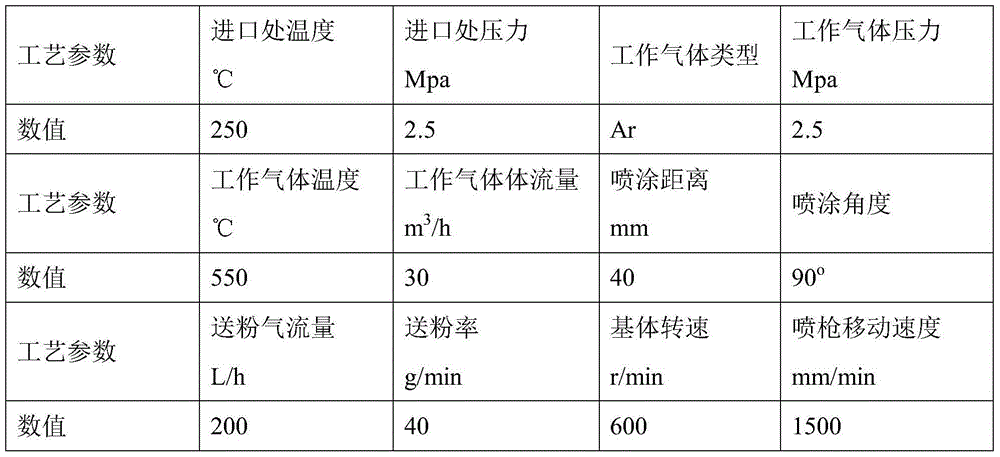

Embodiment 2

[0035] A method for preparing a copper indium gallium rotating target by controlled atmosphere cold spraying, comprising the following steps:

[0036] (1) Ultrasonic cleaning of the stainless steel substrate for 30 minutes, then drying and sandblasting, the sandblasting sand particles are brown corundum, and the particle size is 18 mesh;

[0037] (2) In an argon gas protective atmosphere, use a plasma spraying process to spray nickel-aluminum powder, and prepare a primer layer with a thickness of 0.15mm on the stainless steel substrate after sandblasting;

[0038] (3) In an argon gas protective atmosphere, use a plasma spraying process to spray copper indium powder, and prepare a transition layer with a thickness of 0.1mm on the stainless steel substrate sprayed with a primer layer;

[0039] (4) Use copper indium gallium powder with a D50 of 100 microns and a purity of not less than 99.99% as raw material, put the raw material into a planetary ball mill and grind it for 5 hour...

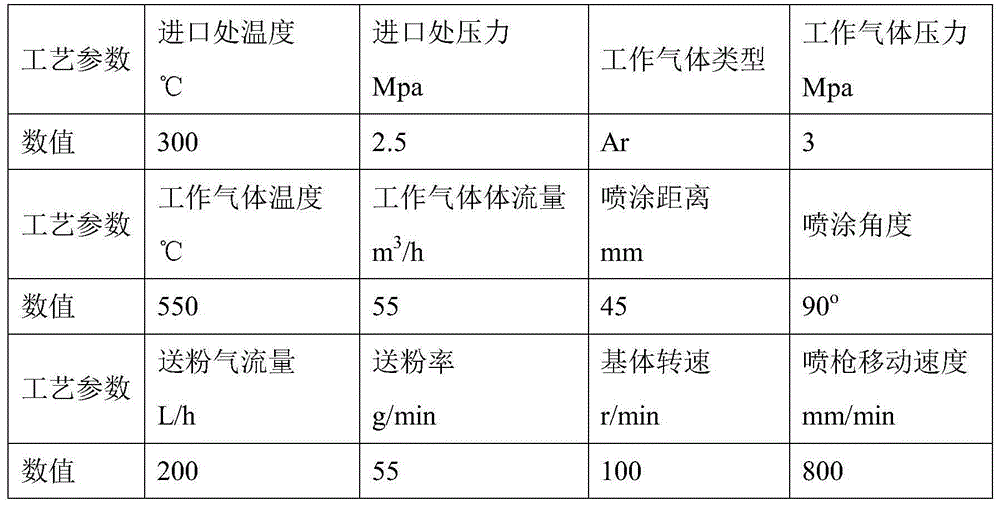

Embodiment 3

[0045] A method for preparing a copper indium gallium rotating target by controlled atmosphere cold spraying, comprising the following steps:

[0046] (1) Ultrasonic cleaning of the stainless steel substrate for 30 minutes, then drying and sandblasting, the sandblasting sand particles are brown corundum, and the particle size is 18 mesh;

[0047] (2) In an argon gas protective atmosphere, use a plasma spraying process to spray nickel-aluminum powder, and prepare a primer layer with a thickness of 0.1mm on the stainless steel substrate after sandblasting;

[0048] (3) In an argon gas protective atmosphere, use a plasma spraying process to spray copper indium powder, and prepare a transition layer with a thickness of 0.15mm on the stainless steel substrate sprayed with a primer layer;

[0049] (4) Use copper indium gallium powder with a D50 of 100 microns and a purity of not less than 99.99% as raw material, put the raw material into a planetary ball mill and grind it for 5 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| oxygen content | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com