A new substance for purifying industrial waste gas

A technology for industrial waste gas and substances, which is applied in air quality improvement, chemical instruments and methods, dispersed particle separation, etc., can solve the problem of high use cost, and achieve the effect of simple preparation process, low preparation cost and low use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

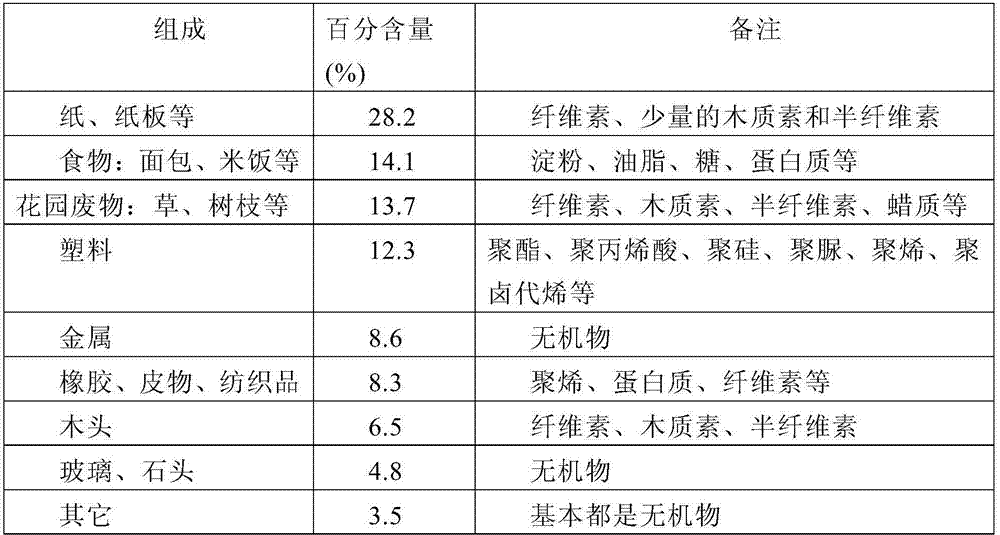

[0039] In order to ensure that the preparation cost of the new substance is as low as possible, the municipal solid waste selected as the raw material, the preparation production process selects the hydrolysis reaction with water as the solvent, so that the waste used as the raw material does not need to be dried.

[0040] The composition of urban domestic solid waste is very complex, and it breeds a large number of microorganisms. The catalyst for the hydrolysis reaction of urban domestic solid waste is a catalyst that is very stable to the hydrolysis system. This catalyst is not poisoned by most traditional catalyst poisoning agents and has many Good water solubility: 9,10-dihydroxy-2,6-disulfonate sodium anthracene (Sodium 9,10-dihydroxyanthracene-2,6-disulfonate).

[0041] In order to ensure that the preparation cost of the new substance is as low as possible, the amount of catalyst used should be as small as possible. In the preparation reaction of the new substance discl...

Embodiment 1

[0058]In a 1-liter high-pressure reactor with stirring function, add 735ml of water, 112g (dry weight, moisture content 18.3%) self-prepared solid waste, 42g quicklime, 0.5g of 9,10-dihydroxy-2, 6-sodium anthracene disulfonate. After the reactor is sealed, replace it with nitrogen for 3 times, then add nitrogen, and keep a certain positive pressure in the reactor to prevent air from entering. Under stirring, heat to 250°C and keep stirring at this temperature for 50-60 minutes. After cooling to below 90°C, slowly release the pressure, then keep the temperature greater than 50°C, press filter to obtain 56.5 grams of solid product A with a moisture content of 28%.

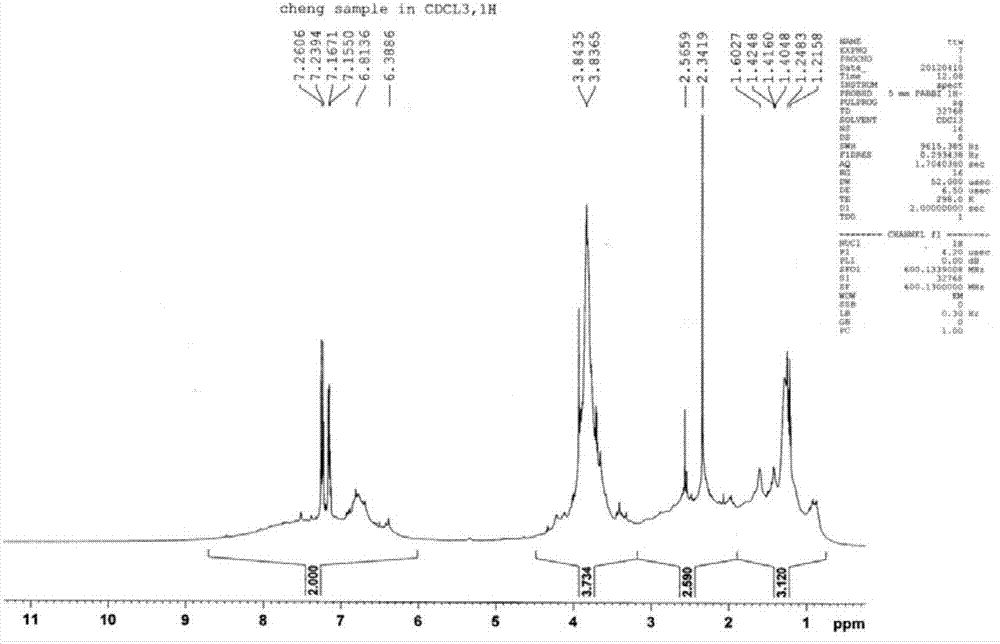

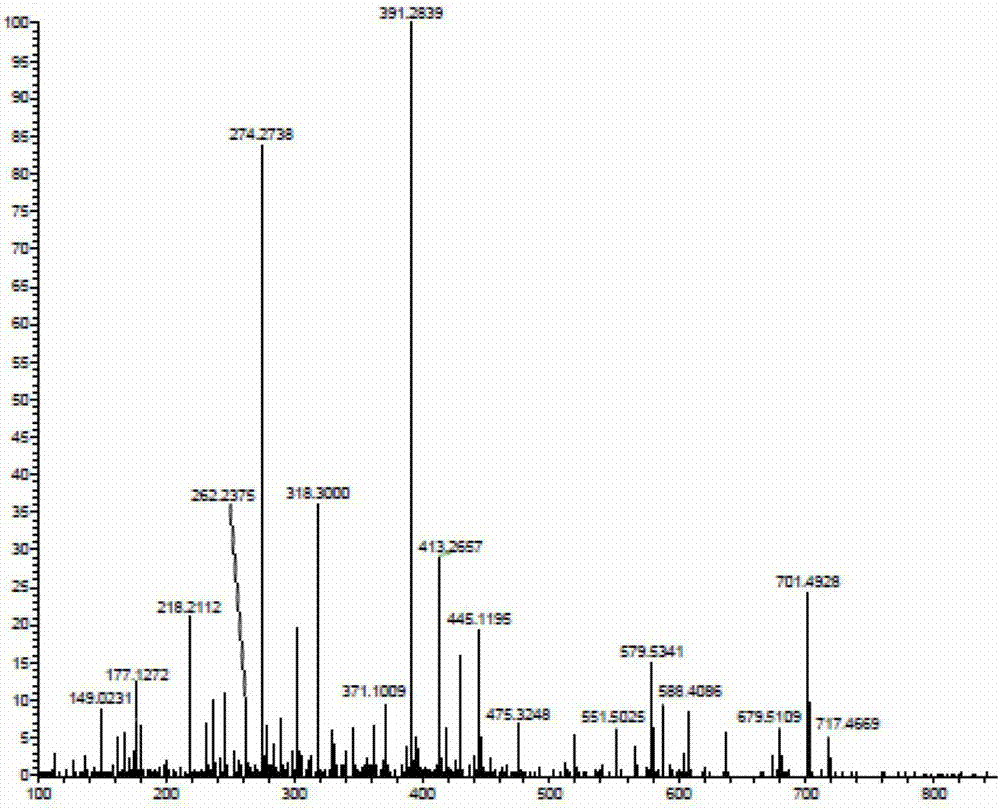

[0059] Vacuum drying to a water content of less than 1% yielded a brown-gray solid product. This product is dispersed in anhydrous methanol, and then, under the condition of controlling the temperature of 40°C, dimethyl sulfate is added dropwise to react to about pH=1, refluxed for 30 minutes, filtered to remove th...

Embodiment 2

[0062] In a 1-liter autoclave with stirring function, add 725ml of water, 135g (dry weight, moisture content 26.5%, ash content 16.5%) collected from the dump and have been winnowed to remove metal, glass, stones municipal solid waste, 42g of quicklime, 0.5g of 9,10-dihydroxy-2,6-disulfonate sodium anthracene. After the reactor is sealed, replace it with nitrogen for 3 times, then add nitrogen, and keep a certain positive pressure in the kettle to prevent air from entering. Under stirring, heat to 250°C and keep stirring at this temperature for 50-60 minutes. After cooling to below 90°C, release the pressure slowly, then keep the temperature greater than 50°C, press filter to obtain 87.1 grams of solid product B with a moisture content of 28%, and an ash content of 43% after drying.

[0063] The results show that the ash in the garbage, the hydrolysis reaction does not convert them into water-soluble substances, and they are still solid when the temperature is greater than 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com