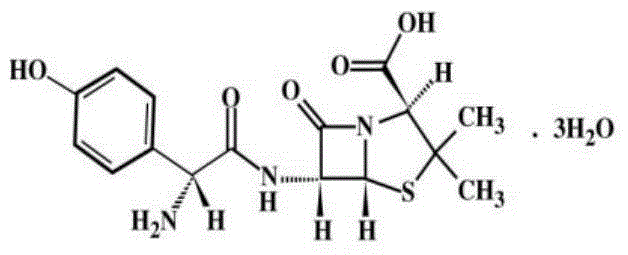

Amoxicillin capsules and preparation method thereof

A technology of amoxicillin capsules and amoxicillin, which is applied in the field of pharmaceutical preparations, can solve the problems of uneven mixing of raw materials and disintegrants, increase the relative amount of co-solvents, and reduce the co-solvent effect of co-solvents, and achieve long-term effects. The effect of stable dissolution, simplified production configuration steps, and shortened preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Amoxicillin capsules, components and contents are configured according to Table 1:

[0031] Table 1 Composition and content of amoxicillin capsules

[0032] serial number

Element

Mass / g

parts by mass

purpose

1

250

100 copies

2

0.875

0.35 parts

Co-solvent

3

3.000

1.2 parts

4

3.000

1.2 parts

[0033] The preparation method of amoxicillin capsule is divided into the following steps:

[0034] (A) Dry granulation: Amoxicillin is air-dried (inlet air temperature is less than 70°C) for 30 seconds and then added to a dry press (roller pressure 9MPa, roller speed 15r / min) for granulation, after granulation Machine sizing (rotating speed 120r / min), rotary vibrating sieve (20 mesh sieve) sieve, obtain amoxicillin heavy powder granule, wherein 82% of amoxi...

Embodiment 2

[0038] Amoxicillin capsules, components and contents are configured according to Table 2:

[0039] Table 2 Composition and Content of Amoxicillin Capsules

[0040] serial number

Element

Weight / g

purpose

1

Amoxicillin

250

100 copies

2

0.600

0.24 parts

Co-solvent

3

Talc powder

3.000

1.2 parts

4

1.475

0.59 parts

[0041] The preparation method of amoxicillin capsule is divided into the following steps:

[0042] (A) Dry granulation: Amoxicillin is air-dried (inlet air temperature is less than 70°C) for 30 seconds into a dry press (roller pressure 7MPa, roller speed 8r / min) for granulation, after granulation Machine sizing (rotating speed 100r / min), rotary vibrating sieve (20 mesh sieve) sieving, obtain amoxicillin heavy powder granule, wherein 70% amoxicillin heavy...

Embodiment 3

[0046] Amoxicillin capsules, components and contents are configured according to Table 3:

[0047] Table 3 Composition and Content of Amoxicillin Capsules

[0048] serial number

Element

Weight / g

parts by mass

purpose

1

Amoxicillin

250

100 copies

2

0.60

0.24 parts

Co-solvent

3

Talc powder

3

1.2 parts

4

Magnesium stearate

1.475

0.59 parts

[0049] The preparation method of amoxicillin capsule is divided into the following steps:

[0050](A) Dry granulation: Amoxicillin is air-dried (inlet air temperature is less than 70°C) for 30 seconds into a dry press (roller pressure 11MPa, roller speed 12r / min) for granulation, and granulated by a granulator. Granules (rotating speed 160r / min), rotary vibrating sieve (20 mesh sieve) sieve, get amoxicillin heavy powder granules, wherein 55% amoxicillin heavy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com