Method for preparing boron or boron-nitrogen doped graphene

A graphene and boron-nitrogen technology, which is applied in the field of preparation of boron-doped or boron-nitrogen graphene, can solve the problems of high equipment requirements and complicated operation, and achieve the effects of large effective specific surface area, simple preparation process, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

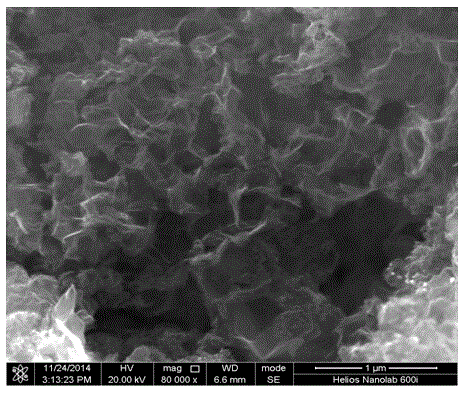

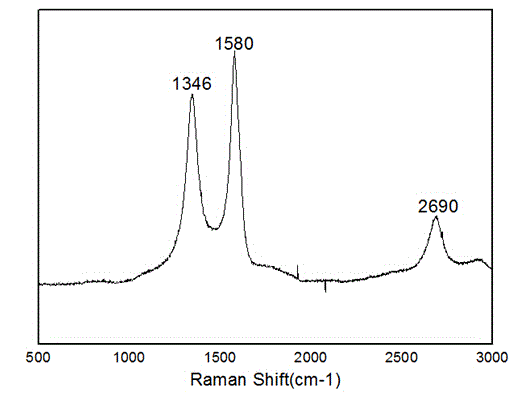

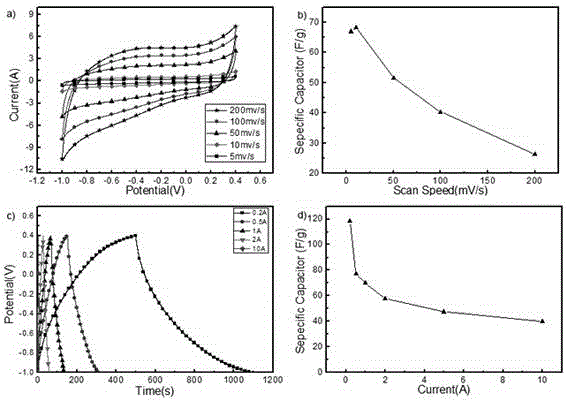

Image

Examples

specific Embodiment approach 1

[0040] (1) Weigh 11.4% boric acid by mass percentage, dissolve it in ethanol solution, then weigh 33.2% magnesium powder and 55.4% calcium carbonate by mass percentage, mix with boric acid solution, and quickly dissolve ethanol under vacuum condition at 90 degrees Celsius Evaporation gave a mixed powder.

[0041] (2) Grinding the powder obtained in step (1) to make the particles fine and mix evenly;

[0042] (3) The mixed powder obtained in step (2) is subjected to a combustion synthesis reaction, and the specific steps are as follows:

[0043] a. Put 100g of mixed powder in a 1L crucible, and add igniter Fe above the mixed powder 3 o 4 + Al;

[0044] b. Then put the crucible into a 20L stainless steel combustion synthesis reactor, and evacuate the interior of the combustion synthesis reaction device;

[0045] C, pass into carbon dioxide in the stainless steel combustion synthesis reactor, make the interior of crucible and stainless steel combustion synthesis reactor be fu...

specific Embodiment approach 2

[0050] (1) Weigh 20% of phenylboronic acid, 30% of magnesium powder and 50% of calcium carbonate by mass percentage to obtain a mixed powder.

[0051] (2) Grinding the powder obtained in step (1) to make the particles fine and mix evenly;

[0052] (3) The mixed powder obtained in step (2) is subjected to a combustion synthesis reaction, and the specific steps are as follows:

[0053] a. Put 1000g of mixed powder in a 10L crucible, and add igniter MnO above the mixed powder 2 +Mg;

[0054] b. Then put the crucible into a 100L stainless steel combustion synthesis reactor, and evacuate the interior of the combustion synthesis reaction device;

[0055] C, pass into carbon dioxide gas in the stainless steel combustion synthesis reactor, make the interior of crucible and stainless steel combustion synthesis reactor be full of carbon dioxide gas;

[0056] d. Using local electric ignition, pass a 20 A DC current through the helical tungsten coil to ignite the igniter MnO 2 +Mg, ma...

specific Embodiment approach 3

[0059] (1) Weigh a mixture of 15% ammonium borate, 30% magnesium powder, and 45% calcium carbonate and magnesium carbonate by mass percentage to obtain a mixed powder.

[0060] (2) Grinding the powder obtained in step (1) to make the particles fine and mix evenly;

[0061] (3) The mixed powder obtained in step (2) is subjected to a combustion synthesis reaction, and the specific steps are as follows:

[0062] a. Put 100g of the mixed powder obtained in step 2 into a 1L crucible, and add the igniter Fe above the mixed powder 3 o 4 +Al;

[0063] b. Then put the crucible into a 20L stainless steel combustion synthesis reactor, and evacuate the interior of the combustion synthesis reaction device;

[0064] C, pass into carbon dioxide in the stainless steel combustion synthesis reactor, make the interior of crucible and stainless steel combustion synthesis reactor be full of carbon dioxide;

[0065] d. Use high-frequency induction ignition to ignite the igniter Fe 3 o 4 +Al, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com