Preparation method of nitrogen-doped graphene

A nitrogen-doped graphene, nitrogen-doped technology, applied in the direction of graphene, nano-carbon, etc., can solve the problems that affect the performance and structural stability of graphene, the equipment and cost requirements are very high, and the structure of nitrogen components is difficult to combine , to achieve the effect of being suitable for mass production and application, low requirements for raw materials and equipment, and high content of nitrogen atoms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038]Natural flake graphite (325 mesh) was placed in a crucible, and argon gas was introduced into the vacuum tube furnace at a flow rate of 0.15 L / min to remove the air in the furnace tube, and then ammonia gas was replaced at a flow rate of 0.1 L / min. The temperature was raised at a rate of 5°C / min to 900°C for 5 hours of heat preservation and heat treatment for nitriding and expansion. After the reaction furnace was naturally lowered to room temperature, the argon gas was changed for 0.5 hours to obtain nitrogen-doped graphite. Disperse nitrogen-doped graphite in N,N-dimethylformamide at a concentration of 0.5mg / mL, and disperse it ultrasonically for 6h at 100W power and 40kHz frequency; Centrifuge under g centrifugal force for 5min, absorb the supernatant with a straw, and obtain nitrogen-doped graphene.

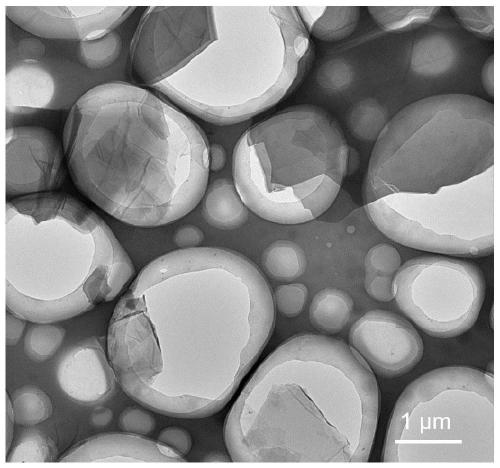

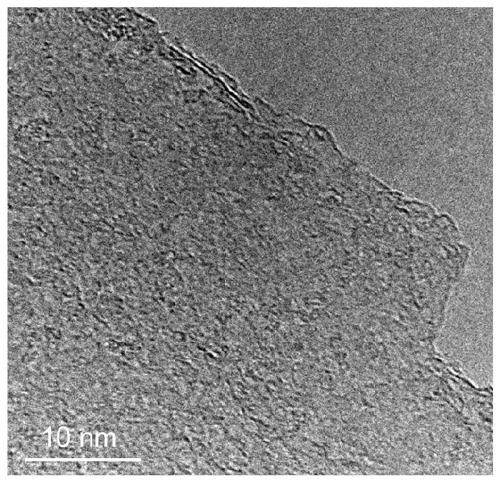

[0039] Such as figure 1 As shown in the TEM photo, the nitrogen-doped graphene sheet prepared in Example 1 has a complete structure, and the size of the graphene sheet...

Embodiment 2

[0041] Natural flake graphite (325 mesh) was placed in a crucible, and argon gas was introduced into the vacuum tube furnace at a flow rate of 0.15 L / min to remove the air in the furnace tube, and then the gas flow was changed to ammonia gas at a flow rate of 0.6 L / min. The temperature was raised at a rate of 2°C / min to 500°C for 12 hours of heat preservation and heat treatment for nitriding and expansion. After the reaction furnace was naturally lowered to room temperature, the argon gas was changed for 0.5 hours to obtain nitrogen-doped graphite. Disperse nitrogen-doped graphite in ethanol at a concentration of 0.05mg / mL, and disperse it ultrasonically for 24h at 300W power and 60kHz frequency; then centrifuge the dispersion at 10000rpm, that is, about 10000×g centrifugal force for 5min, and use a pipette Aspirate the supernatant to obtain nitrogen-doped graphene.

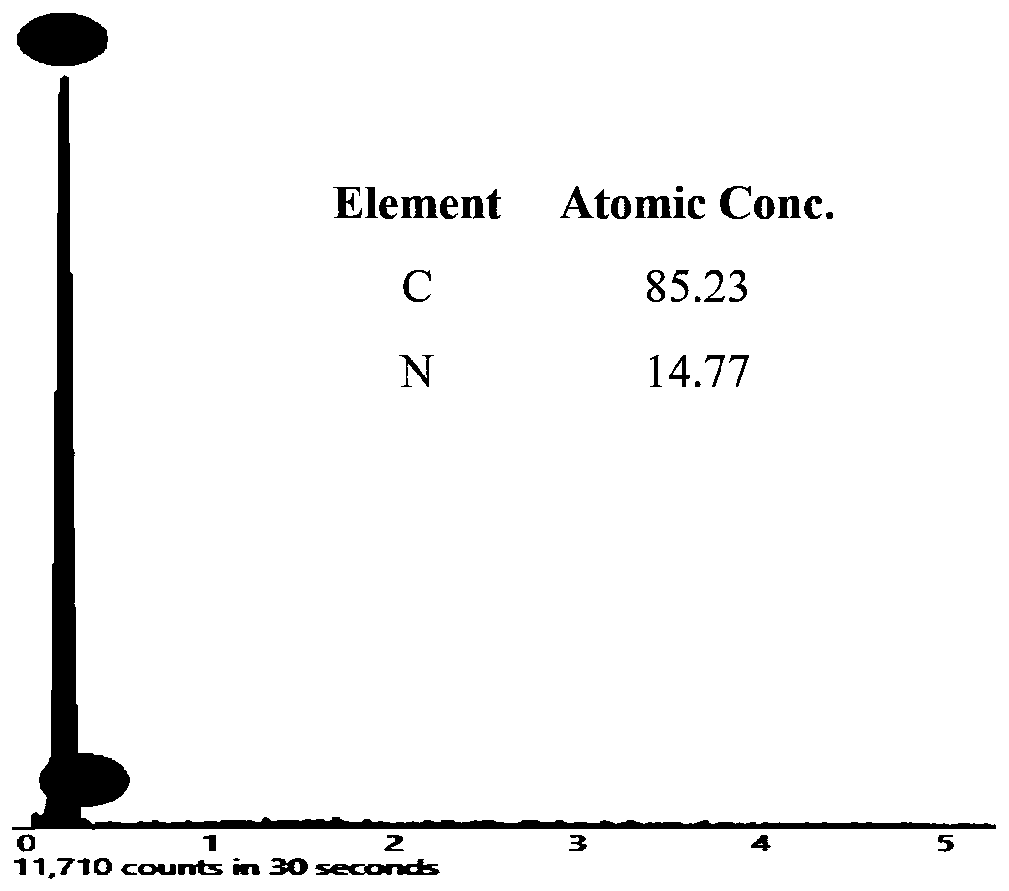

[0042] Such as Figure 4 As shown, the energy spectrum analyzer test result shows that its nitrogen content i...

Embodiment 3

[0044] Natural flake graphite (325 mesh) was placed in a crucible, and argon gas was introduced into the vacuum tube furnace at a flow rate of 0.15 L / min to remove the air in the furnace tube, and then ammonia gas was replaced at a flow rate of 0.1 L / min. The temperature was raised at a rate of 5°C / min to 700°C for 5 hours of heat preservation and heat treatment for nitriding and expansion. After the reaction furnace was naturally lowered to room temperature, the argon gas was changed for 0.5 hours to obtain nitrogen-doped graphite. Disperse nitrogen-doped graphite in tetrahydrofuran at a concentration of 0.5 mg / mL, ultrasonically disperse it for 6 h at 100 W power and 40 kHz frequency; Aspirate the supernatant to obtain nitrogen-doped graphene.

[0045] Such as Figure 5 As shown, the energy spectrum analyzer test result shows that its nitrogen content is 12.99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com