A polymer brush grafted boric acid affinity separation material and its preparation method and application

A separation material, the technology of acrylamide phenylboronic acid, which is applied in the field of separation technology and functional material preparation, can solve the problems of slow mass transfer rate and low adsorption capacity, and achieve the effect of fast mass transfer rate, high adsorption capacity and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Synthesis of m-acrylamidophenylboronic acid monomer

[0030] Dissolve 5 g (30 mmol) of 3-aminophenylboronic acid in 75 mL of 2 mol / L sodium hydroxide at 0 °C, then slowly add 6 mL of cold acryloyl chloride dropwise (over 30 min) to the in the mixed solution. Then slowly add 1mol / L HCl dropwise to make the solution pH=1. A white solid precipitated, filtered, and washed with cold water several times. Saturated sodium chloride was added to the filtrate, and extracted three times with 60 mL of ethyl acetate. The combined organic phases were rotary evaporated and combined with the above white precipitate. Recrystallize in hot water at 60 °C, wash the product with cold water, and dry it in vacuum at 30 °C to obtain needle-like crystals, which are m-acrylamide phenylboronic acid.

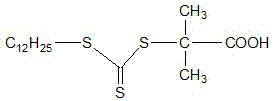

[0031] (2) Synthesis of RAFT reagent DDACT

[0032] Add 16 g (79 mmol) of n-dodecyl mercaptan, 38 g (0.65 mol) of acetone, and 1.3 g of methyl trioctyl ammonium chloride into a 500 mL three...

Embodiment 2

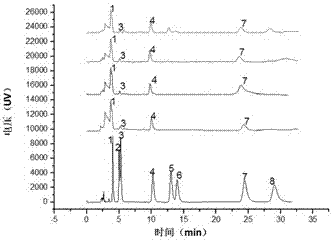

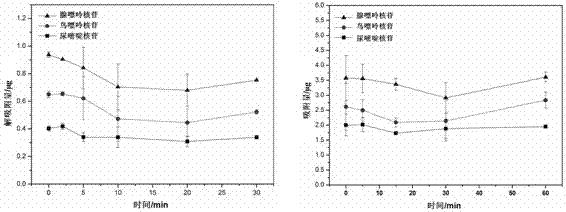

[0033] Example 2: Preparation of polymer brush-grafted boric acid affinity separation material based on surface-ammoniated polymer microspheres

[0034] Disperse 2 g of surface-aminated polymer microspheres in 20 mL redistilled tetrahydrofuran, add 4 g (10 mmol) DDATC, then add 1.2 g (6 mmol) DCC (dicyclohexylcarbodiimide), 1.2 g NHS ( 10 mmol) (N-hydroxysuccinimide), reacted under stirring at room temperature for 48 hours, filtered, and washed with ethanol and acetone for multiple times, respectively, to obtain polymer microspheres modified by RAFT reagent and ammonified on the surface.

[0035] Add 2 g of RAFT reagent-modified polymer microspheres, 30 mL of redistilled N,N-dimethylformamide, 4 g (20 mmol) of m-acrylamidophenylboronic acid, 0.032 g (0.2 mmol) of azo Diisobutyronitrile, using freezing-thawing-vacuum degassing for more than three times, reacted in a 70 °C oil bath for 24 h under the protection of nitrogen, and quenched the schlenk tube in an ice bath to termina...

Embodiment 3

[0036] Example 3: Preparation of polymer brush-grafted boric acid affinity separation material based on surface ammoniated silica gel

[0037] Disperse 2 g of surface-aminated silica gel in 20 mL redistilled tetrahydrofuran, add 4 g (10 mmol) of DDATC, then add 1.2 g of DCC (6 mmol) (dicyclohexylcarbodiimide), 1.2 g of NHS (10 mmol) ( N-hydroxysuccinimide), reacted under stirring at room temperature for 48 hours, filtered, and washed with ethanol and acetone several times respectively to obtain RAFT reagent-modified surface-aminated silica gel.

[0038] Add 2 g RAFT reagent-bonded silica gel, 20 mL redistilled isopropanol, 2 g (10 mmol) m-acrylamidophenylboronic acid, 0.008 g (0.005 mmol) azobisisobutyronitrile to a schlenk tube, and freeze- Thawing-vacuumize and degas more than three times, react in an oil bath at 60 °C for 12 h under nitrogen protection, quench the schlenk tube in an ice bath to terminate the reaction, precipitate with ice methanol, filter, and use N,N-dimethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com