High decorative coating for outer wall and preparation method of high decorative coating

A decorative and exterior wall technology, applied in the field of decorative materials, can solve the problems of water resistance, stain resistance, frost resistance and crack resistance, and low decorative performance, and achieve good decorative effect, good self-cleaning function, and excellent water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

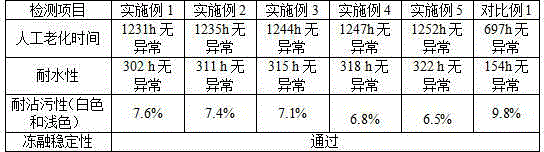

Examples

Embodiment 1

[0018] A highly decorative paint for exterior walls, containing the following components in parts by mass: 20 parts of water, 0.4 parts of ethylene-vinyl acetate copolymer, 10 parts of calcite powder, anatase nano-TiO 2 5 parts of powder, 3 parts of zinc oxide whisker, 1 part of sericite, 2 parts of kaolin, 0.3 part of polydimethylsiloxane, 0.2 part of molecular sieve, 3 parts of succinimide, 2-amino-2-methanol 0.1 part of 1-propanol, 0.1 part of octyl acrylate, 0.15 part of tributyltin chloride, 0.008 part of cumene hydroperoxide, 1 part of propylene glycol, 0.7 part of self-crosslinking elastic acrylic emulsion, 30 parts of silicone emulsion share.

[0019] A preparation method of high decorative paint for exterior wall, the preparation steps of the method are as follows:

[0020] The first step: first mix water, ethylene-vinyl acetate copolymer, calcite powder, anatase nano-TiO 2 Add the powder, zinc oxide whiskers, sericite, and kaolin into the paint mixing tank, control...

Embodiment 2

[0024] A highly decorative paint for exterior walls, containing the following components in parts by mass: 30 parts of water, 0.8 parts of ethylene-vinyl acetate copolymer, 22 parts of calcite powder, anatase nano-TiO 2 12 parts of powder, 9 parts of zinc oxide whiskers, 5 parts of sericite, 7 parts of kaolin, 0.7 parts of polydimethylsiloxane, 0.48 parts of molecular sieve, 7 parts of succinimide, 2-amino-2-methanol 0.3 parts of 1-propanol, 0.3 parts of octyl acrylate, 0.45 parts of tributyltin chloride, 0.015 parts of cumene hydroperoxide, 4 parts of propylene glycol, 3.2 parts of self-crosslinking elastic acrylic emulsion, 44 parts of silicone emulsion share.

[0025] A preparation method of high decorative paint for exterior wall, the preparation steps of the method are as follows:

[0026] The first step: first mix water, ethylene-vinyl acetate copolymer, calcite powder, anatase nano-TiO 2 Add powder, zinc oxide whiskers, sericite, and kaolin into the paint mixing tank,...

Embodiment 3

[0030] A highly decorative paint for exterior walls, containing the following components in parts by mass: 23 parts of water, 0.5 parts of ethylene-vinyl acetate copolymer, 12 parts of calcite powder, anatase nano-TiO 2 6 parts of powder, 4 parts of zinc oxide whisker, 2 parts of sericite, 3 parts of kaolin, 0.4 part of polydimethylsiloxane, 0.24 part of molecular sieve, 4 parts of succinimide, 2-amino-2-methanol 0.13 parts of 1-propanol, 0.16 parts of octyl acrylate, 0.2 parts of tributyltin chloride, 0.009 parts of cumene hydroperoxide, 1.8 parts of propylene glycol, 1 part of self-crosslinking elastic acrylic emulsion, 33 parts of silicone emulsion share.

[0031] A preparation method of high decorative paint for exterior wall, the preparation steps of the method are as follows:

[0032] The first step: first mix water, ethylene-vinyl acetate copolymer, calcite powder, anatase nano-TiO 2 Add powder, zinc oxide whiskers, sericite, and kaolin into the paint mixing tank, contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com