Organic electroluminescent device and preparation method thereof

An electroluminescent device and electroluminescent technology, which is applied in the fields of electro-solid devices, semiconductor/solid-state device manufacturing, and electrical components, etc., can solve the problems of reduced luminous efficiency of light-emitting devices, increased operating voltage and decreased stability of light-emitting devices, etc. Improve hole injection efficiency, reduce operating voltage, and increase the effect of logarithm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides a preparation method for the above-mentioned organic electroluminescent device, the steps of which are:

[0033] a) Pretreatment of anode conductive substrate

[0034] Use ITO glass (that is, indium tin oxide transparent conductive glass) as the anode conductive substrate, and wash it with detergent, deionized water, acetone and ethanol successively, and clean it with an ultrasonic cleaner. , stop for 5 minutes, repeat the method 3 times, and then dry it in an oven for use; the cleaned ITO glass also needs surface activation treatment to increase the oxygen content on the surface of the ITO glass and improve the ITO glass. The work function of the surface; the thickness of ITO glass is 100-150nm;

[0035] b) Preparation of the first hole injection layer

[0036] Using N,N'-diphenyl-N,N'-di(1-naphthyl)-1,1'-biphenyl-4,4'-diamine (NPB), 4,4',4'' -Tris(carbazol-9-yl)triphenylamine (TCTA), 4,4'-bis(9-carbazole)biphenyl (CBP), N,N'-bis(...

Embodiment 1

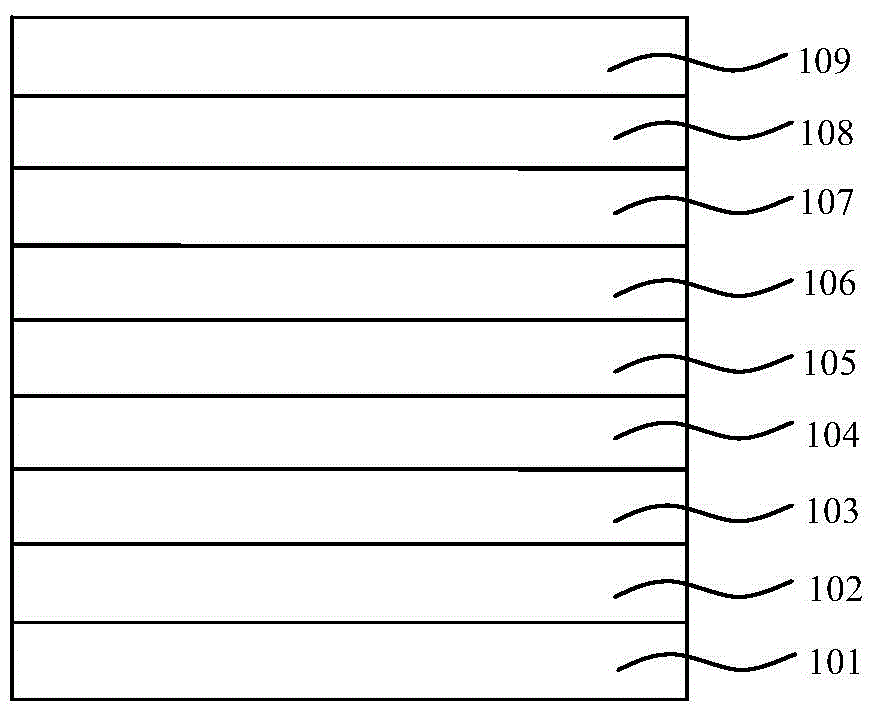

[0053] Such as figure 1 As shown, the present embodiment 1 provides an organic electroluminescent device, the organic electroluminescent device has a layered structure, and the organic electroluminescent device includes in sequence: an anode conductive substrate 101, a first hole injection layer 102 , a first electron injection layer 103 , a second hole injection layer 104 , a hole transport layer 105 , a green light emitting layer 106 , an electron transport layer 107 , a second electron injection layer 108 and a cathode layer 109 .

[0054] The expression of the organic electroluminescent device is: ITO glass / MoO 3 :NPB(30:100) / Cs 2 CO 3 :Bphen(30:100) / MoO 3 :NPB(30:100) / NPB / Ir(ppy) 3 :TCTA(10:100) / Bphen / Cs 2 CO 3 :Bphen(30:100) / Ag, wherein, the colon ":" indicates that the former is doped in the latter.

[0055] The present embodiment 1 also provides the preparation method of the above-mentioned organic electroluminescence device, and its steps are:

[0056] a) Pret...

Embodiment 2

[0075] Such as figure 1 As shown, this embodiment 2 provides an organic electroluminescent device, the organic electroluminescent device is a layered structure, and the organic electroluminescent device includes in sequence: an anode conductive substrate 101, a first hole injection layer 102 , a first electron injection layer 103 , a second hole injection layer 104 , a hole transport layer 105 , a green light emitting layer 106 , an electron transport layer 107 , a second electron injection layer 108 , and a cathode layer 109 .

[0076] The expression of the organic electroluminescent device is: ITO glass / WO 3 :TCTA(25:100) / CsF:BCP(25:100) / WO 3 :TCTA(25:100) / TCTA / Ir(ppy) 2 (acac):mCP(2:100) / BCP / CsF:BCP(25:100) / Al, wherein the colon ":" indicates that the former is doped in the latter.

[0077] This embodiment 2 also provides the preparation method of the above-mentioned organic electroluminescence device, and its steps are as follows:

[0078] a) Pretreatment of the anode ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com