Collagen/silk fibroin composite support and manufacturing method and application thereof

A technology of silk fibroin and composite scaffold, applied in medical science, prosthesis, etc., can solve the problems of inaccessibility, poor strength, etc., and achieve the effects of good mechanical properties, favorable adhesion and excellent biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

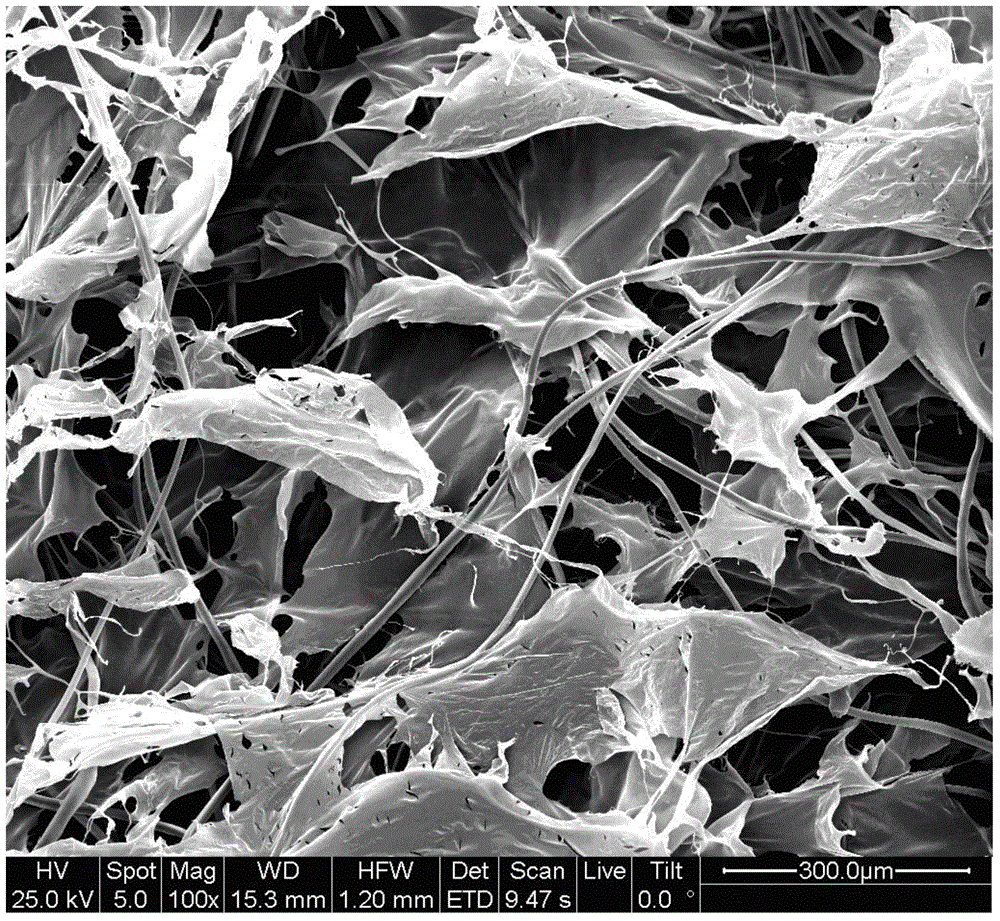

[0022] A collagen / silk fibroin composite scaffold, comprising a collagen-based porous scaffold and a silk non-woven fabric, the silk non-woven fabric is more tightly integrated in the collagen-based porous scaffold, and the collagen-based porous scaffold has 30- 500μm pore size structure; silk fibroin non-woven fabric has good three-dimensional porous structure and permeability, the pore size range is between 20-3000μm, and the diameter of a single cooked silk is about 10μm, such as figure 1 shown.

[0023] The quantitative relationship between the silk fibroin nonwoven fabric and the collagen-based scaffold can be adjusted according to the different uses of the scaffold and the properties of the target tissue / organ. In addition to collagen, the materials used to prepare collagen-based porous scaffolds can also use chitosan, hyaluronic acid, silk fibroin, chondroitin sulfate, glycosaminoglycans, elastin and its hydrolyzate, laminin, Bone morphogenic protein, cellulose, etc. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com