Synthetic method and application of visible-light responding carbon nitride/iron sesquioxide nano composite

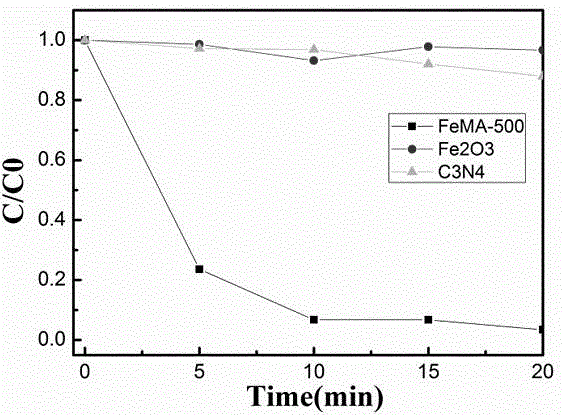

A nano-composite material, ferric oxide technology, applied in chemical instruments and methods, light water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of high photogenerated electron-hole recombination rate and carbon nitride ratio Low surface area, low utilization rate of solar energy, etc., to achieve the effect of simple process, low price of raw materials, and improved photocatalytic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

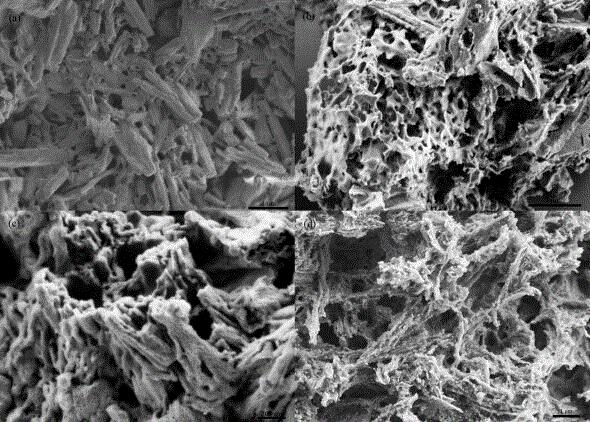

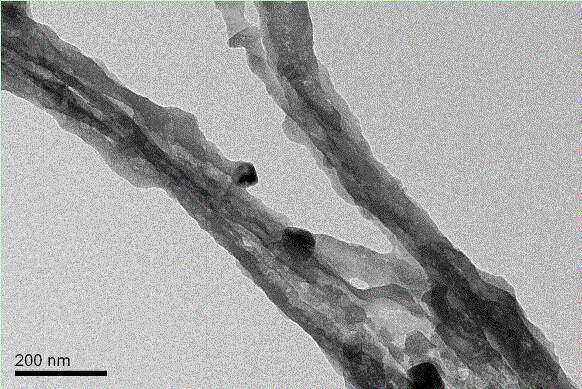

[0023] Example 1 Preparation of Carbon Nitride / Fe2O3 Composite Material

[0024] Put 2.5g of melamine and 8.0g of ferric nitrate powder into a round bottom flask with 200ml of methanol as the solvent. Put the round-bottomed flask in a constant temperature magnetic stirrer, react for 3 hours, filter to obtain the precursor, put the prepared material into a porcelain boat, put it into a tube furnace, and heat up at a rate of 1 °C / min in an argon atmosphere. The room temperature was raised to 400° C. and kept at a constant temperature for 3 hours, and the argon flow rate was 60 cc / min. After cooling to room temperature, the carbon nitride / Fe2O3 nanocomposite material was obtained.

Embodiment 2

[0025] Example 2 Preparation of Carbon Nitride / Fe2O3 Composite Material

[0026] Put 2.5g of melamine and 8.0g of ferric nitrate powder into a round bottom flask with 200ml of methanol as the solvent. Put the round-bottomed flask in a constant temperature magnetic stirrer, react for 3 hours, filter to obtain the precursor, put the prepared material into a porcelain boat, put it into a tube furnace, and heat up at a rate of 2°C / min in an argon atmosphere. The room temperature was raised to 500°C and kept at a constant temperature for 3 hours, and the argon flow rate was 70 cc / min. After cooling to room temperature, the carbon nitride / Fe2O3 nanocomposite material was obtained.

Embodiment 3

[0027] Example 3 Preparation of Carbon Nitride / Fe2O3 Composite Material

[0028] Put 2.5g of melamine and 8.0g of ferric nitrate powder into a round bottom flask with 200ml of methanol as the solvent. Put the round-bottom flask in a constant temperature magnetic stirrer, react for 3 hours, filter to obtain the precursor, put the prepared material into a porcelain boat, put it into a tube furnace, and press the heating rate of 3 °C / min in an argon atmosphere. The room temperature was raised to 550°C and kept at a constant temperature for 3 hours, and the argon flow rate was 80 cc / min. After cooling to room temperature, the carbon nitride / Fe2O3 nanocomposite material was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com