Method for detecting dissolution rate of colloidal bismuth pectin preparation

A technology of colloidal bismuth pectin and dissolution rate, which is applied in the direction of testing pharmaceutical preparations, material analysis through observation of the influence on chemical indicators, and measuring devices, which can solve the problem of low repeatability and accuracy of determination methods and inability to measure accurately Solve the problems of bismuth pectin dissolution rate and low recovery rate of dissolution rate, and achieve the effect of improving controllability, good dissolution curve and dissolution rate, and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

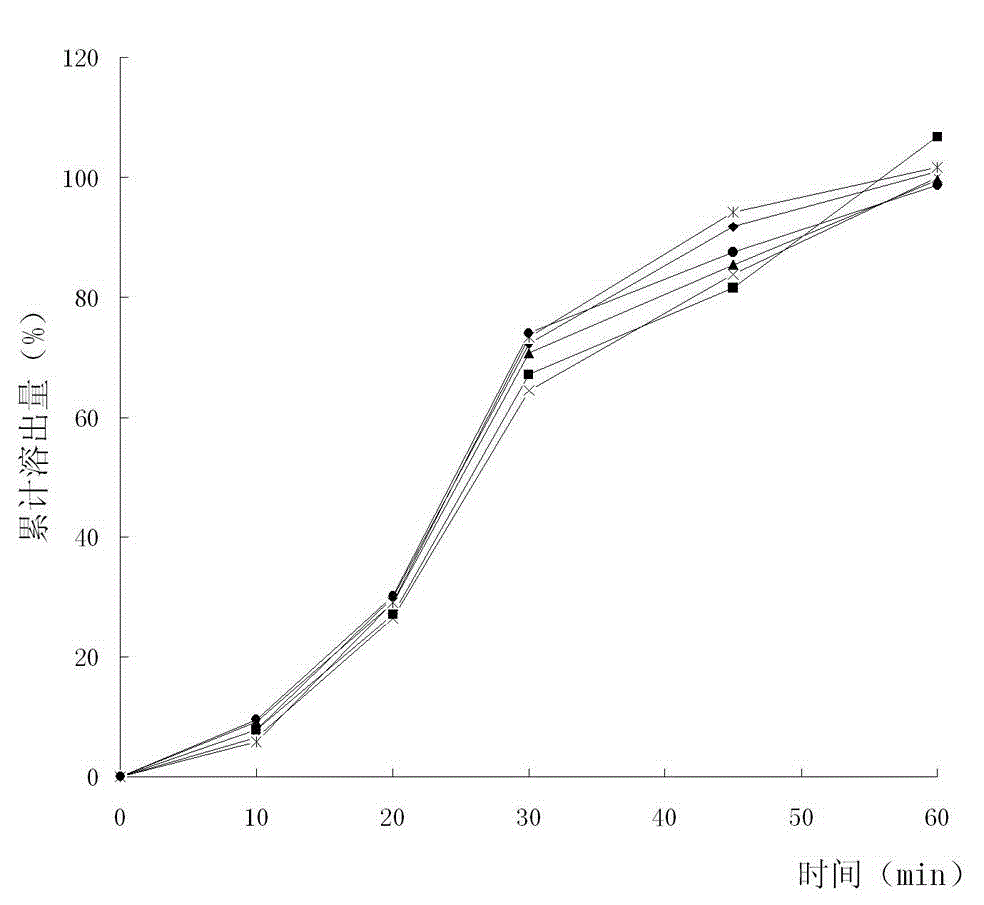

[0028] Example 1: Colloidal pectin bismuth dispersible tablets (specification 50 mg, calculated as bismuth).

[0029] 1) Preparation of chromogenic solution: Take 5g of ascorbic acid and 25g of potassium iodide, put them in a 200ml volumetric flask, add 100ml of water, shake to dissolve, add 25ml of 1mol / L nitric acid solution, dilute with water and set the volume to the mark to make 2.5% ascorbic acid , Potassium iodide 12.5% chromogenic solution.

[0030] 2) Preparation of bismuth reference substance solution: Take 275 mg of bismuth metal, accurately weigh it, put it in a 100 ml volumetric flask, add 6.4 ml of nitric acid to dissolve, dilute with water to the mark, and use it as a bismuth standard stock solution. Precisely measure 2ml of bismuth standard stock solution, put it in a 100ml volumetric flask, dilute to the mark with 1mol / L nitric acid solution, and make a solution containing 55μg of bismuth per 1ml, as the bismuth standard solution. Precisely measure 5ml of b...

Embodiment 2

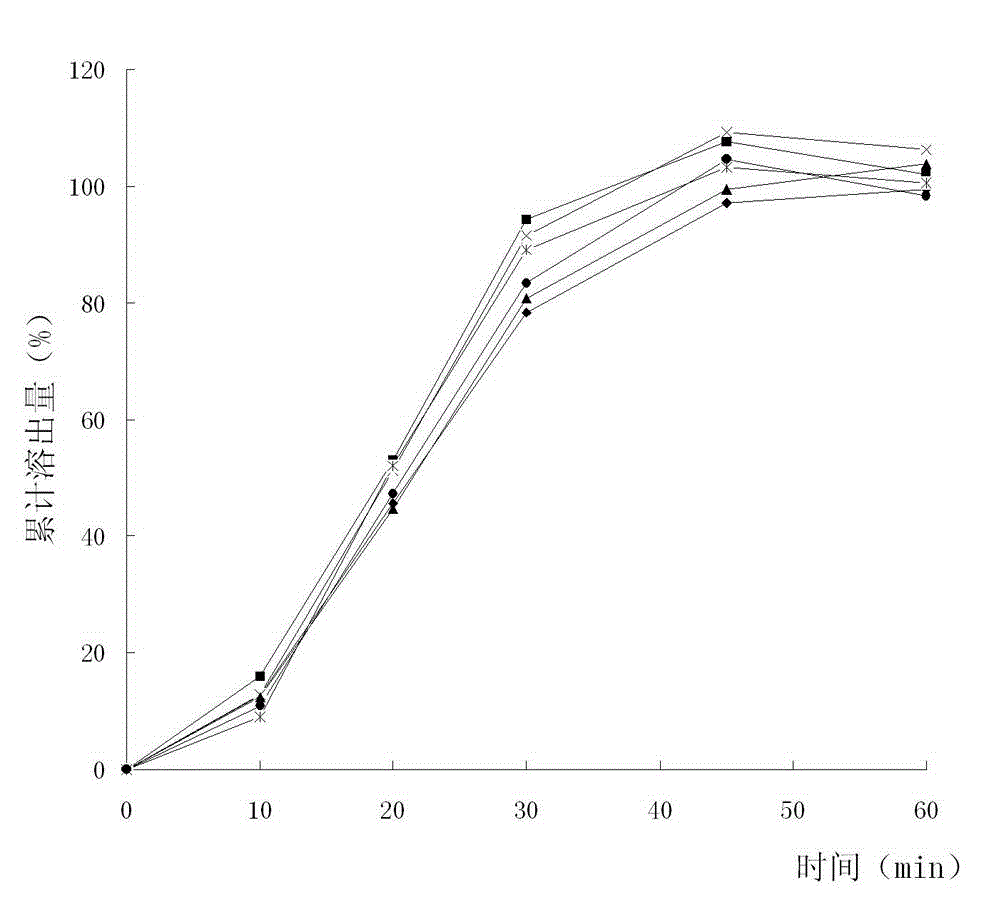

[0035] Example 2: Colloidal pectin bismuth enteric-coated tablets (specification 100 mg, calculated as bismuth).

[0036] 1) Preparation of chromogenic solution: Take 15g of citric acid and 50g of potassium iodide, put them in a 200ml volumetric flask, add 100ml of water, shake to dissolve, add 25ml of 2mol / L nitric acid solution, dilute with water and set the volume to the mark to make Chromogenic solution of 7.5% acid and 25% potassium iodide.

[0037] 2) Preparation of bismuth reference substance solution: Take 275 mg of bismuth metal, accurately weigh it, put it in a 100 ml volumetric flask, add 6.4 ml of nitric acid to dissolve, dilute with water to the mark, and use it as a bismuth standard stock solution. Take 2ml of bismuth standard stock solution, put it in a 50ml volumetric flask, add 1.2mol / L nitric acid solution to dilute to the mark, and make a solution containing 110μg of bismuth per 1ml, as the bismuth standard solution. Precisely measure 5ml of bismuth standar...

Embodiment 3

[0042] Embodiment 3: colloidal bismuth pectin capsules (specification 50 mg, calculated as bismuth).

[0043] 1) Preparation of chromogenic solution: Take 1g of citric acid and 5g of potassium iodide, put them in a 200ml volumetric flask, add 100ml of water, shake to dissolve, add 25ml of 10mol / L nitric acid solution, dilute with water and set the volume to the mark to make lemon Chromogenic solution of 0.5% acid and 2.5% potassium iodide.

[0044] 2) Preparation of bismuth reference substance solution: Take 275 mg of bismuth metal, accurately weigh it, put it in a 100 ml volumetric flask, add 6.4 ml of nitric acid to dissolve, dilute with water to the mark, and use it as a bismuth standard stock solution. Take 1ml of bismuth standard stock solution, put it in a 100ml volumetric flask, add 1.1mol / L hydrochloric acid solution to dilute to the mark, and make a solution containing 27.5μg of bismuth per 1ml, as the bismuth standard solution. Precisely measure 1ml of bismuth stand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com