Method for conditioning fermentation acid production sludge to raise organic acid recovery by utilization of seed sludge rich in thiobacillus

A technology of sludge and seed sludge, applied in sludge treatment, biological sludge treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problems of large dosage, high cost, loss of organic acids in fermentation liquid, etc. , to achieve high processing efficiency, short processing time, and improve the efficiency of solid-liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1, Preparation of Seed Mud Enriched with Thiobacillus thiooxidans and Thiobacillus ferrooxidans

[0038] Put 250mL of excess sludge obtained from the concentration tank of the sewage treatment plant into a 500mL conical flask, and add 2g / L of Fe at the same time 2+ (FeSO 4 ·7H 2 O, FeS or other reducing iron can also be used) and 2g / L sulfur powder (FeS or other reducing sulfur can also be used). Place the triangular flask in a constant temperature water bath shaker to cultivate and enrich the indigenous strains by shaking, the shaker rotates at 100 rpm, and the temperature is normal or medium temperature, that is, 15-40°C, such as 28°C. When the acidification pH of the sludge drops below 4.5, one cycle ends. The acidified sludge was inoculated into fresh excess sludge at a ratio of 2% (V / V), and cultured under the same conditions until the pH dropped below 4.5. The above steps were repeated three times, and the obtained acidified sludge was used as seed slu...

Embodiment 2

[0039] Embodiment 2, utilize the seed mud conditioning concentration of the present invention to be the fermentation acid production sludge of 40g / L

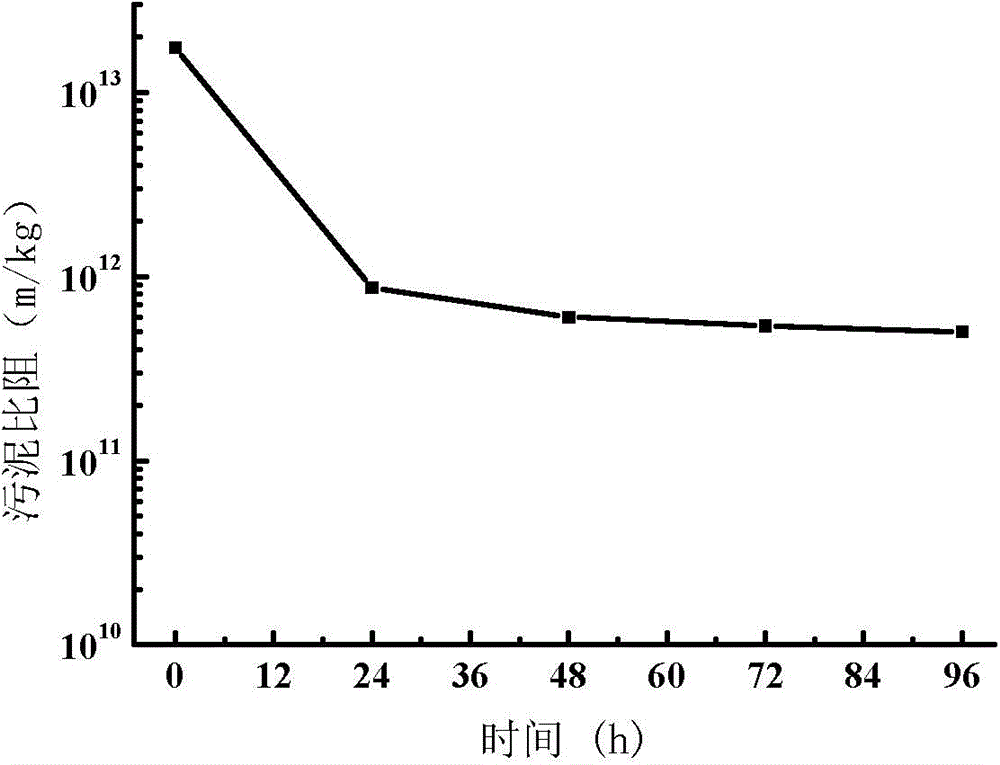

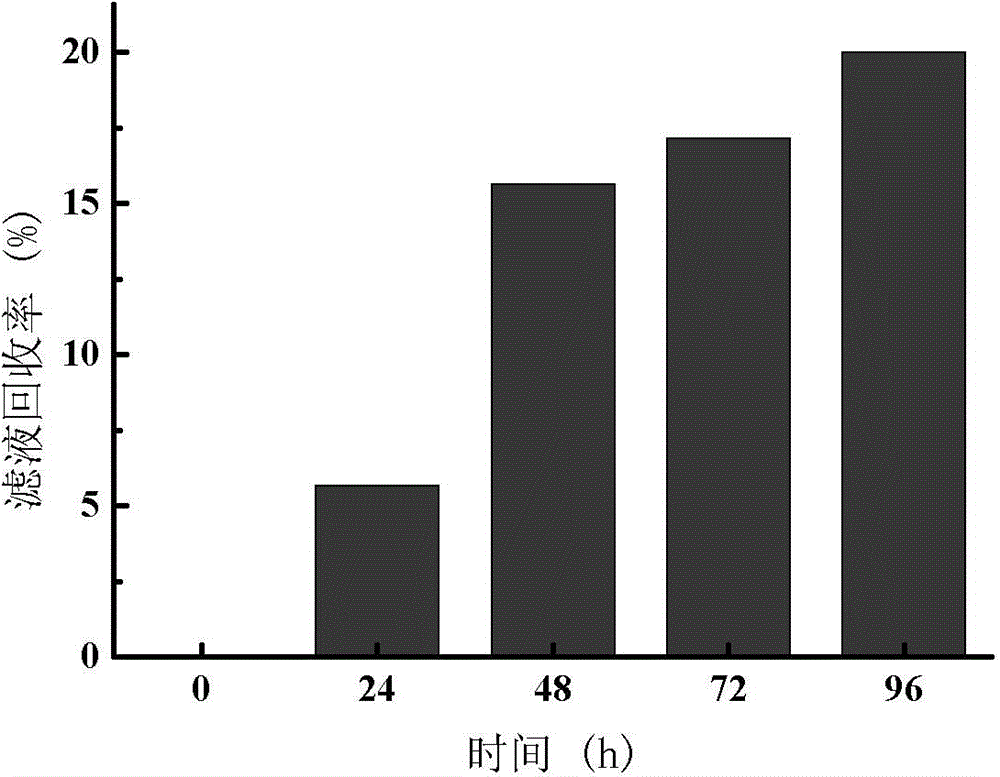

[0040] The fermented sludge inoculated with the seed sludge prepared in Example 1 was cultured under shaking and aeration conditions. Test with a shaker and an aerator. The effective volume of the reactor is 500mL. Take an appropriate amount of seed sludge and inoculate it into 40g / L of fermented acid-producing sludge. The inoculum volume is 2% (V / V), and add 2g / L LFeSO 4 ·7H 2 O and 2g / L sulfur powder, the cultivation temperature is 15-40°C. Shaker shaking culture, 100rpm, culture 96h. At 24h, the specific resistance of sludge changed from 1.75×10 13 m / kg dropped to 8.66×10 11 m / kg, decreased to 5.01×10 after 96h 11 ( figure 1 ). Under normal pressure filtration, the filtrate recovery rate increased from 0 to 20% ( figure 2 ), the organic acid recovery rate increased to 20.47%.

Embodiment 3

[0041] Embodiment 3, utilize the seed mud conditioning concentration of the present invention to be the fermentation acid production sludge of 20g / L

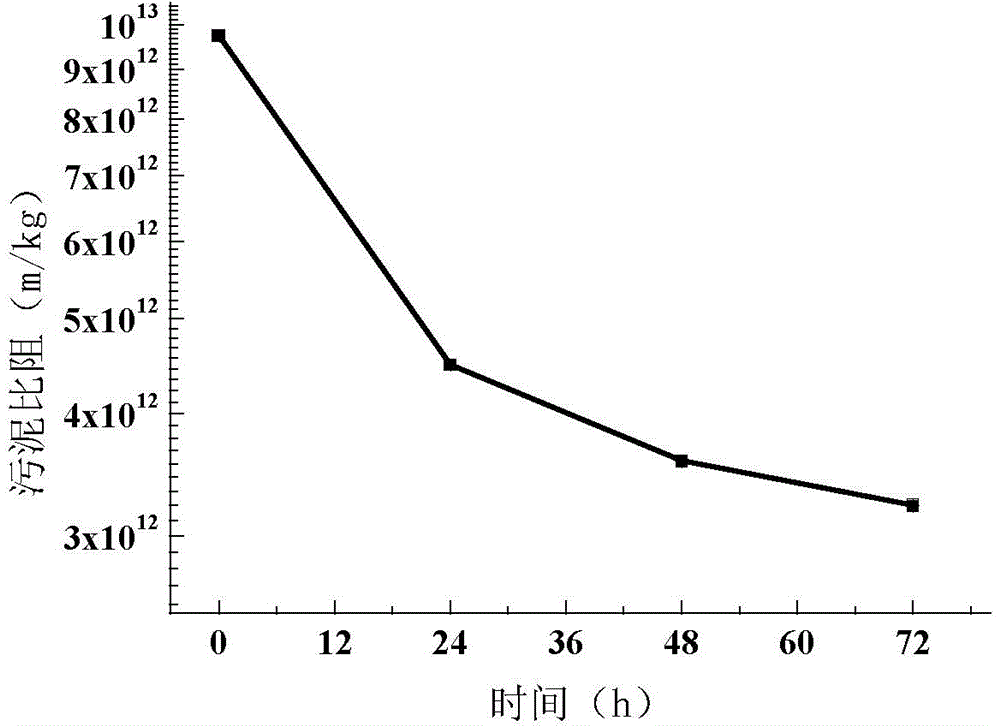

[0042]The fermented sludge inoculated with the seed sludge prepared in Example 1 was cultured under shaking and aeration conditions. Test with a shaker and an aerator, the effective volume of the reactor is 500mL, take an appropriate amount of seed sludge and inoculate it into 20g / L of fermented sludge, the inoculum volume is 2% (V / V), and add 2g / L of FeSO 4 ·7H 2 O and 2g / L sulfur powder, the cultivation temperature is 15-40°C. Shaker shaking culture, 100rpm, culture 72h. Sludge specific resistance from 9.72×10 12 m / kg down to 3.22×10 12 m / kg( image 3 ). The suction filtration effect of the sludge before conditioning is very poor, and the sludge can form mud cake after suction filtration conditioning ( Figure 4 ), the moisture content is 75.17%. The filtrate is effectively recovered, and under normal pressure filtrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com