Plating solution carrying out chemical palladium plating on copper surface and preparation method therefor

A copper surface and electroless plating technology, applied in liquid chemical plating, metal material coating process, coating, etc., can solve the problem of reducing copper wire balling, bonding performance and reliability, long plating time, cumbersome Eliminate issues such as sensitization and activation steps to achieve excellent bath stability, shorten induction time, and increase deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

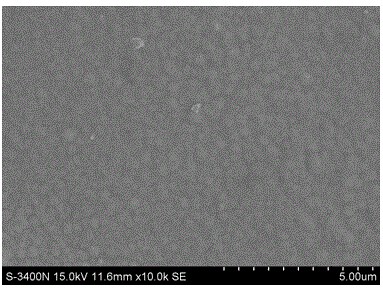

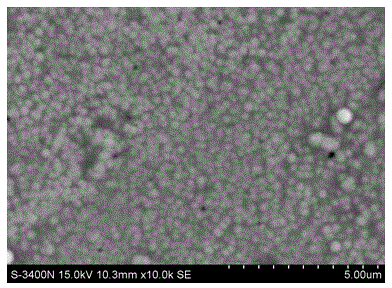

Image

Examples

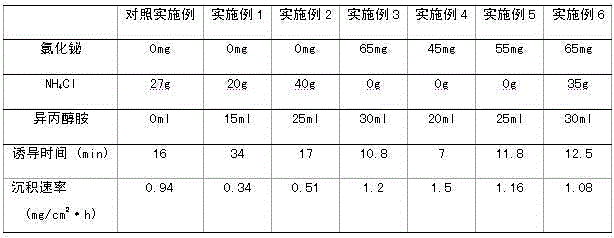

Embodiment 1

[0051] A kind of plating solution that carries out electroless palladium plating on copper surface, by every liter, its raw material composition and content are as follows:

[0052] PdCl 2 1g

[0053]Concentrated ammonia water 80ml

[0054] NaH 2 PO 2 ·H 2 O 8g

[0055] NH 4 Cl 20g

[0056] Bismuth chloride 0mg

[0057] Isopropanolamine 15ml;

[0058] The balance is distilled water.

[0059] Above-mentioned a kind of preparation method of the plating solution that carries out electroless palladium plating on copper surface, step is as follows:

[0060] Add 20g of ammonium chloride and 15ml of isopropanolamine to 80ml of ammonia water to obtain an ammonia solution containing ammonium chloride and isopropanolamine, then slowly add 1g of palladium chloride under stirring, leave it for 24h, and then continue 8gNaH 2 PO 2 ·H 2 O is added therein slowly, then adds distilled water and is constant to 1L, obtains the plating solution that carries out elect...

Embodiment 2

[0081] A kind of plating solution that carries out electroless palladium plating on copper surface, by every liter, its raw material composition and content are as follows:

[0082] PdCl 2 2g

[0083] Concentrated ammonia water 160ml

[0084] NaH 2 PO 2 ·H 2 O 12g

[0085] NH 4 Cl 40g

[0086] Bismuth chloride 0mg

[0087] Isopropanolamine 25ml

[0088] The balance is distilled water.

[0089] Above-mentioned a kind of preparation method of the plating solution that carries out electroless palladium plating on copper surface, step is as follows:

[0090] Add 40g of ammonium chloride and 25ml of isopropanolamine to 160ml of ammonia water to obtain an ammonia solution containing ammonium chloride and isopropanolamine, then slowly add 2g of palladium chloride under stirring, leave it for 24h, and then continue 12gNaH 2 PO 2 ·H 2 O is added therein slowly, then adds distilled water and is constant to 1L, obtains the plating solution that carries out e...

Embodiment 3

[0111] A kind of plating solution that carries out electroless palladium plating on copper surface, by every liter, its raw material composition and content are as follows:

[0112] PdCl 2 3g

[0113] Concentrated ammonia water 180ml

[0114] NaH 2 PO 2 ·H 2 O 14g

[0115] NH 4 Cl 0g

[0117] Isopropanolamine 30ml;

[0118] The balance is distilled water.

[0119] Above-mentioned a kind of preparation method of the plating solution that carries out electroless palladium plating on copper surface, step is as follows:

[0120] Add 65mg of bismuth chloride and 30ml of isopropanolamine to 180ml of ammonia water to obtain an ammonia solution containing bismuth chloride and isopropanolamine, then slowly add 3g of palladium chloride under stirring conditions, leave it for 24h, and then continue to 14gNaH 2 PO 2 ·H 2 O is added therein slowly, then adds distilled water and is constant to 1L, obtains the plating solution that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com