Gadolinium oxide ceramics and method for manufacturing same

A technology of gadolinium oxide and ceramics, which is applied in the field of nuclear industry protective materials, can solve problems affecting the scope of use, and achieve the effects of easy industrial production, easy operation, and high neutron absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

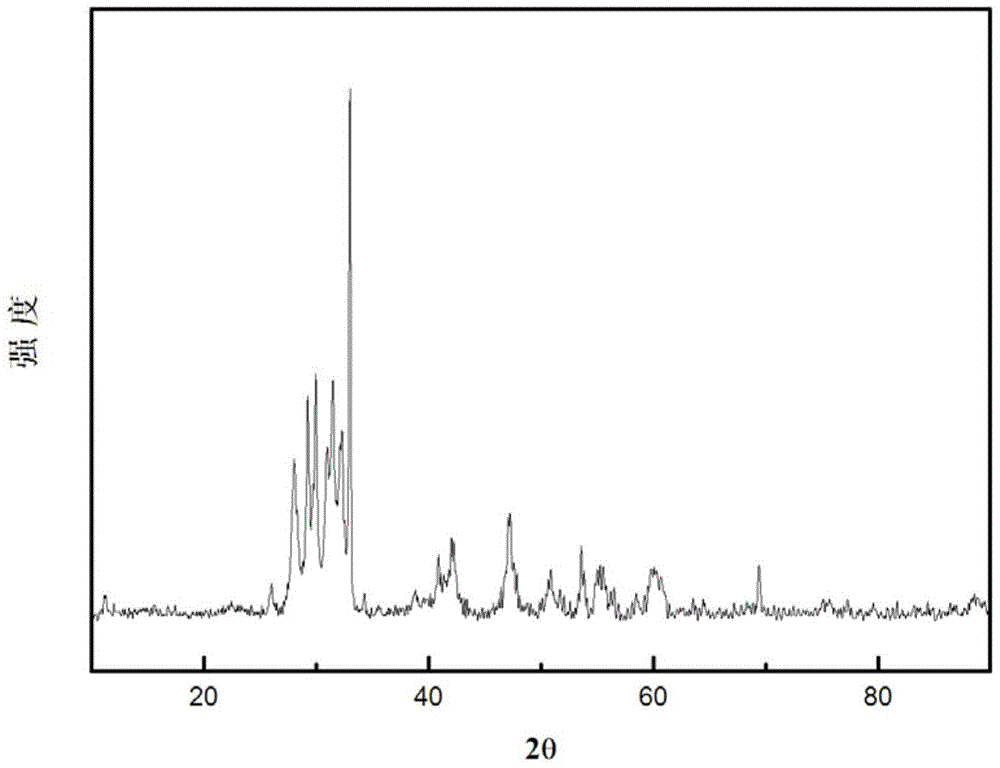

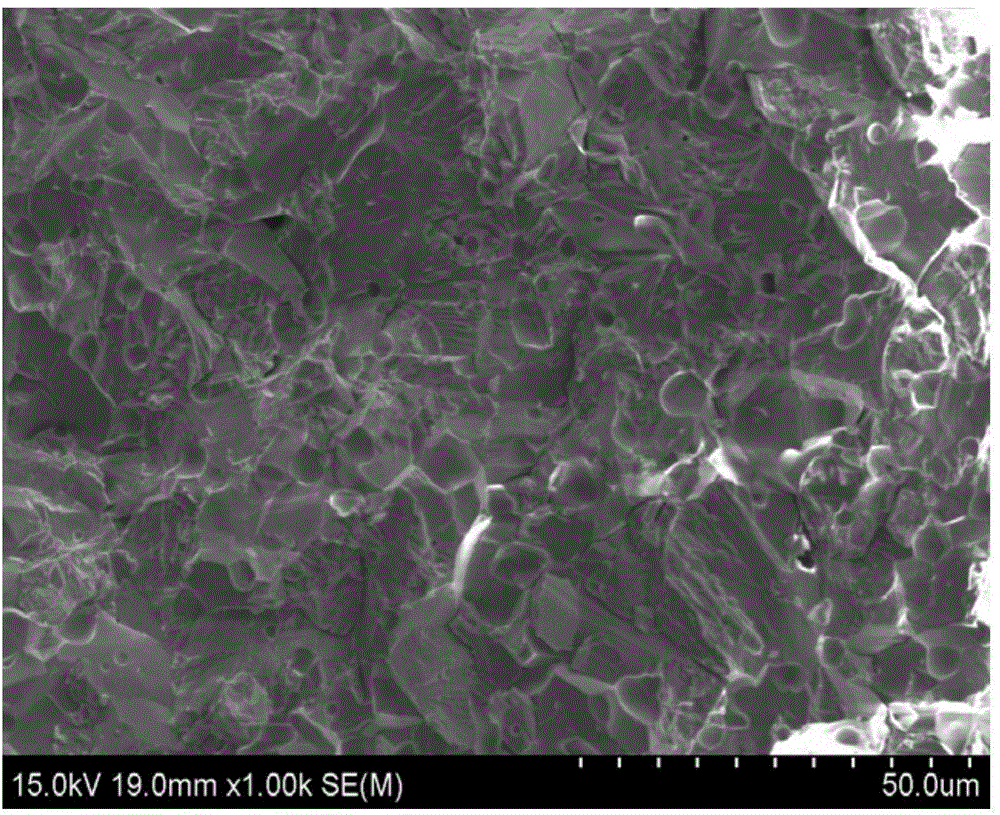

Image

Examples

Embodiment 1

[0054] The specific raw material components of gadolinium oxide ceramics are as follows: 98 parts of gadolinium oxide and 2 parts of yttrium aluminum garnet.

[0055] The preparation method steps are as follows:

[0056] (1) According to the above parts by mass, use absolute ethanol as the medium and zirconia balls as the grinding medium to mix gadolinium oxide and yttrium aluminum pomegranate in a polyurethane ball mill tank for 4 hours, and the slurry mixed by ball milling under vacuum conditions Dried to obtain a mixed powder;

[0057] (2) The mixed powder obtained in step (1) is added with a binder (5%wt PVA aqueous solution) of 5‰ of the total mass of the mixed powder, added to a cylindrical abrasive tool, and pre-pressed with a hydraulic press. 25Mpa, pressed into a round cake-shaped sample; and then isostatically pressed in an isostatic press under a pressure of 150MPa to obtain a molded green body;

[0058] (3) Dry the molded green body obtained in step (2) and place...

Embodiment 2

[0062] The specific raw material components of gadolinium oxide ceramics are as follows: 99 parts of gadolinium oxide and 1 part of titanium oxide.

[0063] The preparation method steps are as follows:

[0064] (1) According to the above mass parts, use absolute ethanol as the medium for gadolinium oxide and titanium oxide, and use zirconia ball stone as the grinding medium, mix the planetary ball mill in the polyurethane ball mill tank for 2 hours, and dry the slurry mixed by ball milling under vacuum conditions dry, mixed powder;

[0065] (2) The mixed powder obtained in step (1) is added with a binder (5%wt PVA aqueous solution) of 5‰ of the total mass of the mixed powder, added to a cylindrical abrasive tool, and pre-pressed with a hydraulic press. 30Mpa, pressed into a round cake-shaped sample; and then isostatically pressed under a pressure of 180MPa in an isostatic press to obtain a molded green body;

[0066] (3) Dry the molded green body obtained in step (2) and pla...

Embodiment 3

[0070] The specific raw material components of gadolinium oxide ceramics are as follows: 99 parts of gadolinium oxide and 1 part of aluminum oxide.

[0071] The preparation method steps are as follows:

[0072] (1) According to the above mass parts, use absolute ethanol as the medium for gadolinium oxide and aluminum oxide, and use zirconia ball stone as the grinding medium, mix the planetary ball mill in the polyurethane ball mill tank for 5 hours, and dry the slurry mixed by ball milling under vacuum conditions dry, mixed powder;

[0073] (2) The mixed powder obtained in step (1) is added with a binder (5%wt PVA aqueous solution) of 5‰ of the total mass of the mixed powder, added to a cylindrical abrasive tool, and pre-pressed with a hydraulic press. 15Mpa, pressed into a round cake-shaped sample; and then isostatically pressed in an isostatic press under a pressure of 100MPa to obtain a molded green body;

[0074] (3) Dry the molded green body obtained in step (2) and pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com