Compound ionic liquid braunification liquid for printed-circuit boards

A technology of printed circuit boards and ionic liquids, which is applied in the secondary treatment of printed circuits, the improvement of the metal adhesion of insulating substrates, and the coating process of metal materials. problem, to achieve the effects of low toxicity, excellent heat resistance, and increased chemical bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The technical route of browning process is as follows:

[0030] Pickling→water washing→alkaline degreasing→water washing→presoaking→browning→pure water washing→drying→pressing

[0031] The specific operation of the above technical route is as follows:

[0032] (1) Pickling: use 3%-5% dilute sulfuric acid as the cleaning agent, and wash away other metal impurities loaded on the copper surface at 30°C;

[0033] (2) Water washing: wash repeatedly at room temperature with deionized water until the lotion is basically neutral;

[0034] (3) Alkaline degreasing: Use TS-Alkclean 6215 alkaline degreasing agent produced by Guangdong Dongshuo Technology Co., Ltd. to wash the above-mentioned PCB board after washing at 60°C. Its purpose is to effectively remove dry film photoresist residues, grease, fingerprints and other pollutants on the copper surface and remove the surface oxide layer to prepare for later browning;

[0035] (4) Washing: use deionized water to wash repeatedly ...

Embodiment 2

[0053] The difference between this embodiment and embodiment 1 is:

[0054] (1) A compound ionic liquid browning solution for printed circuit boards, whose raw materials consist of:

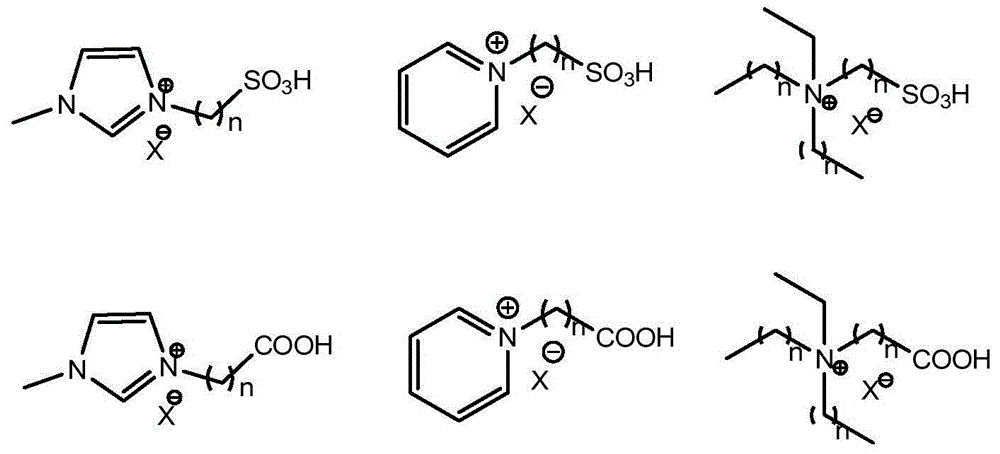

[0055] Ionic liquid acid: 1-methyl-4-propanesulfonic acid imidazolium sulfate ionic liquid 100g;

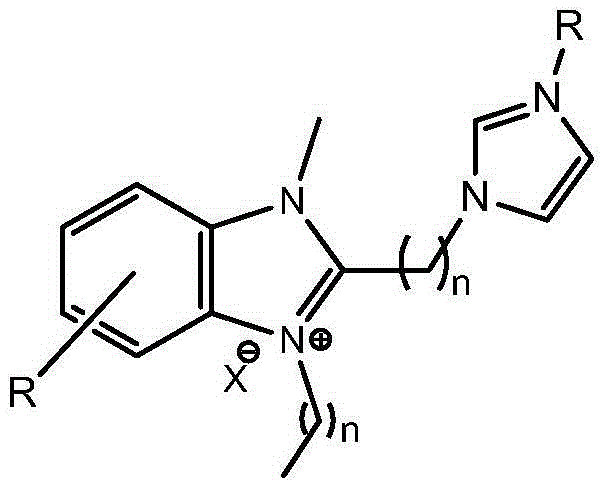

[0057] Ionic liquid corrosion inhibitor 1‐methyl‐2‐(4‐ethylimidazole)‐4‐butylnitrobenzimidazole chloride salt 10g;

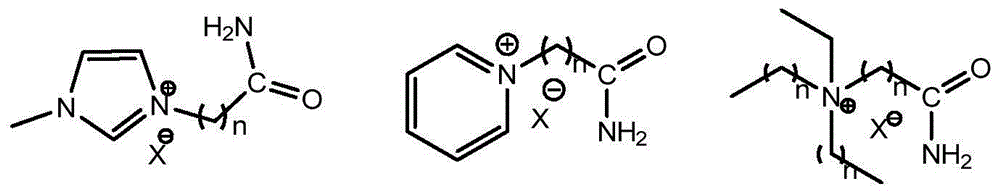

[0058] Ionic liquid binding force promoter 1-methyl-4-acetamido imidazolium chloride 1.0g;

[0059] The ingredients were mixed and diluted to 1 L with deionized water.

[0060] (2) The browning temperature is 30°C, and the browning time is 50s.

[0061] After testing, the density of the browning solution is 1.15g / mL; the pH value is 3.2; the copper loading can reach 52g / L, and the micro-etching rate of the copper surface is 55μin / min; and the copper surface can be evenly rough after browning treatment The surface has a stable bonding force and exce...

Embodiment 3

[0063] The difference between this embodiment and embodiment 1 is:

[0064] (1) A compound ionic liquid browning solution for printed circuit boards, whose raw materials consist of:

[0065] Ionic liquid acid: 1‐methyl‐4‐butanesulfonic acid imidazolium dihydrogen phosphate ionic liquid 90g;

[0067] Ionic liquid corrosion inhibitor 1‐methyl‐2‐(4‐octylimidazole)‐4‐butyl p-toluimidazole chloride 15g;

[0068] Ionic liquid binding force promoter 1-methyl-4-acetamidoimidazolium bromide 2.5g;

[0069] The above mixture was diluted to 1 L with deionized water.

[0070] (2) The browning temperature is 40°C, and the browning time is 60s.

[0071] The research results show that the density of the browning solution is 1.35g / mL; the pH value is 3.8; the copper loading can reach 38g / L, and the micro-etching rate of the copper surface is 54μin / min; Rough surface, stable bonding force with prepreg and excellent heat resistance, under the condition of 288...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com