Microstructure fiber biochip and manufacturing method thereof

A microstructure optical fiber and biochip technology, which is applied in biochemical equipment and methods, enzymology/microbiology devices, and determination/inspection of microorganisms, etc. effect and other problems, to achieve the effect of low cost of detection instruments, realization of stimulated emission amplification, and improvement of fluorescence conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

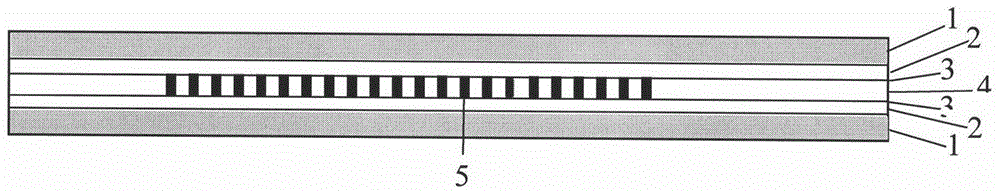

[0025] HLA-DRB Oligonucleotide Microstructure Optical Fiber Biochip and Its Preparation

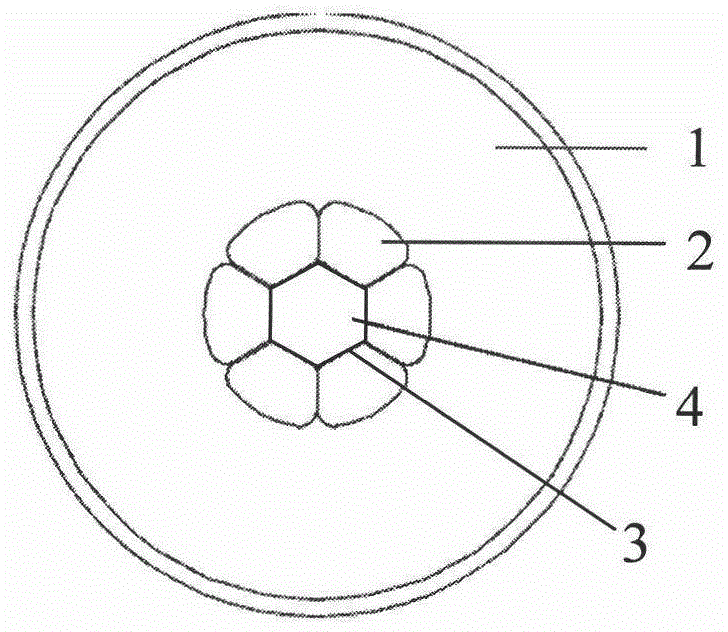

[0026] 1) Preparation of optical fiber

[0027] Take a section of microstructured optical fiber, and use a selective filling method to block the peripheral air holes, leaving only the central air hole unblocked.

[0028] 2) Preparation of nanomagnetic beads

[0029] Take 1 mg of carboxylated magnetic beads with a diameter of 15 nanometers, wash 3 times, adjust the pH value to the isoelectric point, and fully disperse the nano magnetic beads.

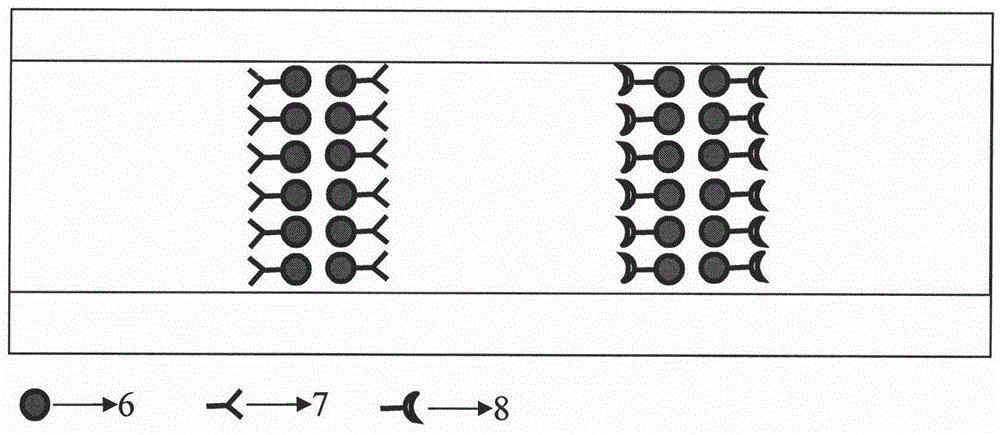

[0030] 3) Coupling nano magnetic beads with probes

[0031] The designed and synthesized HLA-DRB probes are fully mixed and reacted with nano-magnetic beads, and the unreacted reagents are eluted.

[0032] 4) Fabrication of Microstructure Optical Fiber Biochip

[0033] The reacted nano-magnetic bead-molecular probe solution is added to the gravity perfusion device 12, and flows into the core hole of the microstructured optical fiber 15 through t...

Embodiment 2

[0039] Microstructure fiber optic biochip for HbsAg detection

[0040] In the implementation step 3 of the above coupling of nano-magnetic beads and probes, the sandwich-like magnetic immunoassay method is used, with the help of magnetic particles as solid-phase carriers, and through the combination of streptavidin and biotin, quantum Points are markers. There is a special force between streptavidin and biotin, the binding force between them is extremely strong, the binding speed is fast and the binding efficiency is high. Firstly, the magnetic beads are coupled with streptavidin, the anti-HbsAg is coupled with biotin, and the magnetic beads and anti-HbsAg are immobilized together through the combination of streptavidin and biotin. In step 5 of the above sample pretreatment, the test sample is marked with quantum dots, and then the presence of the test substance in the sample is detected by antigen-antibody reaction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com