Rapid preparation method of inorganic compound coated aqueous phase II-VI group quantum dot composite material

A composite material and quantum dot technology, which is applied in the field of rapid preparation of inorganic-coated aqueous phase II-VI quantum dot composite materials, can solve the problems of low efficiency of quantum dot coating by sodium chloride and long synthesis time, etc. Achieve the effect of low cost, good stability and strong fluorescence emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Stir and dissolve 0.04g sodium borohydride, 0.046g tellurium powder and 2ml deionized water under a nitrogen atmosphere until the solution turns light pink to obtain an anion precursor;

[0023] 2. Dissolve 0.114g of cadmium chloride in 100ml of deionized water, add 0.133g of mercaptopropionic acid, adjust the pH of the solution to 8.0 with 1M sodium hydroxide solution, and pass nitrogen gas for 30 minutes to obtain a cationic precursor;

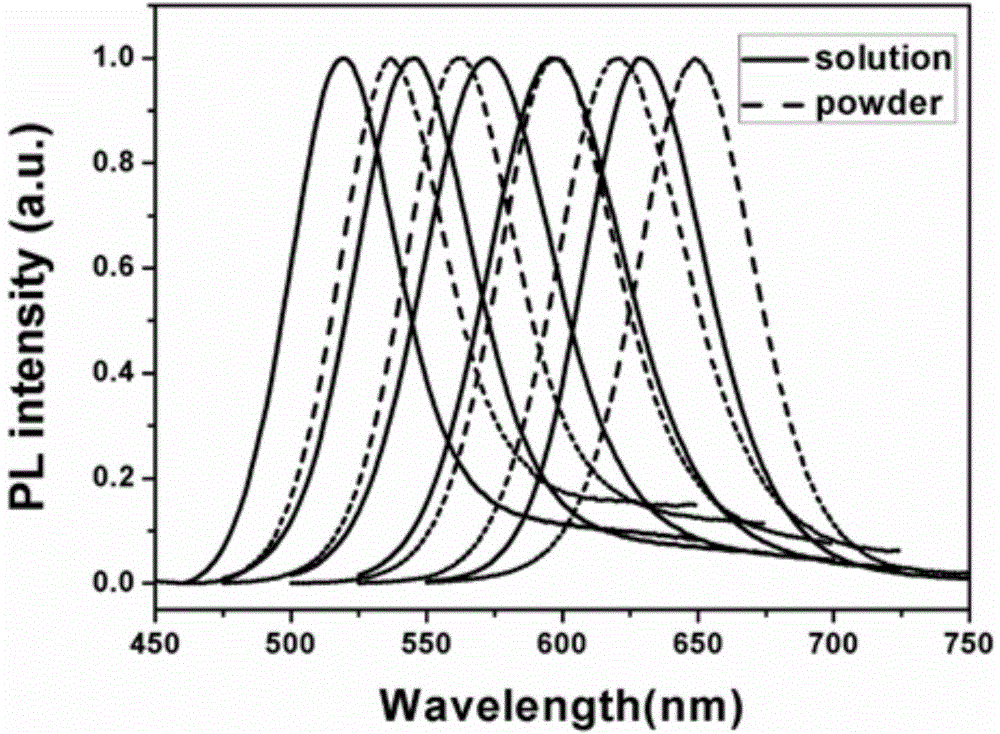

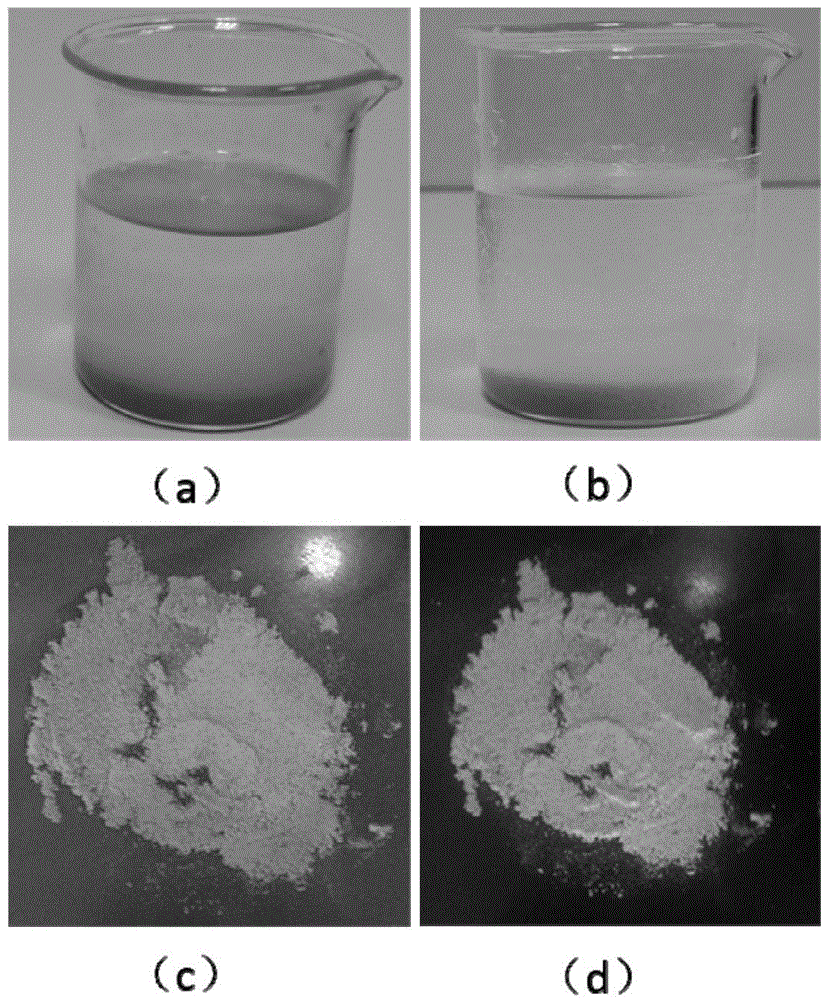

[0024] 3. Inject 400 μl of the anion precursor solution prepared in step 1 into the cationic precursor solution prepared in step 2 under stirring, heat to 90°C and reflux, take 20 mL samples at 1, 3, 5, 7, and 10 hours of reaction, and cool to room temperature , to obtain cadmium telluride quantum dot solutions with different wavelengths.

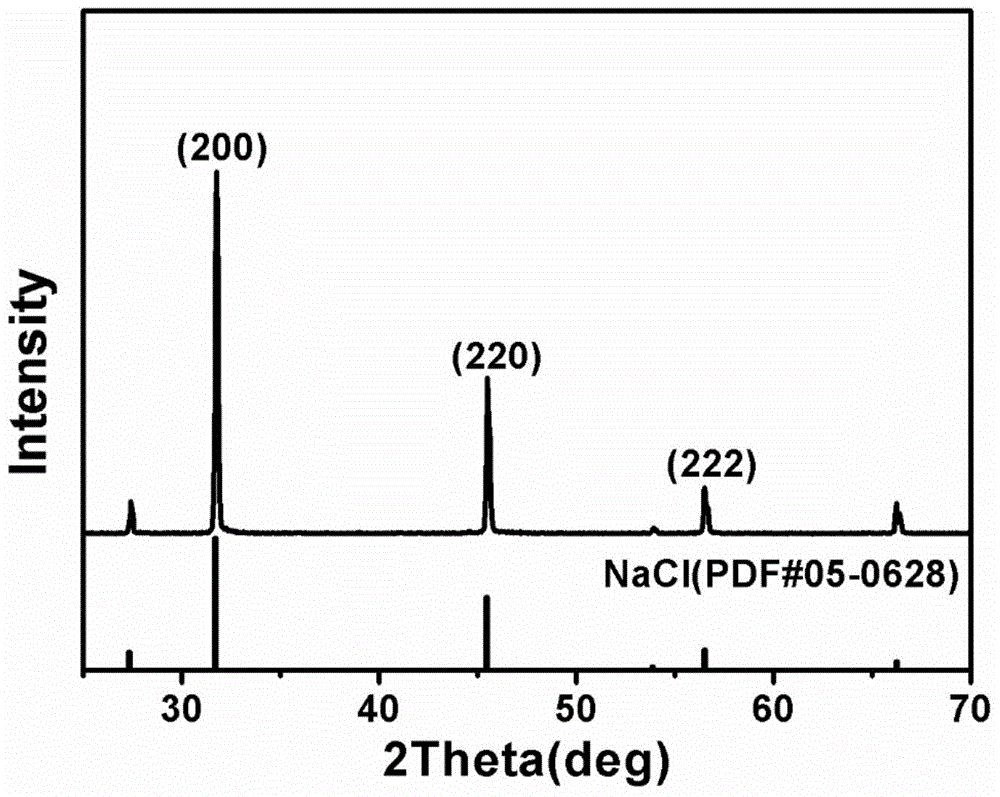

[0025] 4. Dissolve 5g of sodium chloride in the 20ml cadmium telluride quantum dot solution prepared in step 3, quickly add 50ml of ethanol under stirring, generate a precipitate, filter, dry, a...

Embodiment 2

[0027] 1. Stir and dissolve 0.04g sodium borohydride, 0.046g tellurium powder and 2ml deionized water under a nitrogen atmosphere until the solution turns light pink to obtain an anion precursor;

[0028] 2. Dissolve 0.114g of cadmium chloride in 100ml of deionized water, add 0.092g of mercaptoacetic acid, adjust the pH of the solution to 8.0 with 1M sodium hydroxide solution, and pass nitrogen gas for 30 minutes to obtain a cationic precursor;

[0029] 3. Inject 400 μl of the anion precursor solution prepared in step 1 into the cation precursor solution prepared in step 2 under stirring, heat to 90° C. for reflux reaction for 9 hours, stop heating, and cool to room temperature to obtain a cadmium telluride quantum dot solution.

[0030] 4. Dissolve 5g of sodium sulfate in 100ml of cadmium telluride quantum dot solution prepared in step 3, quickly add 200ml of methanol under stirring, generate precipitate, filter, dry, and grind into fine powder to obtain cadmium telluride quan...

Embodiment 3

[0032] 1. Stir and dissolve 0.04g sodium borohydride, 0.046g tellurium powder and 2ml deionized water under a nitrogen atmosphere until the solution turns light pink to obtain an anion precursor;

[0033] 2. Dissolve 0.114g of cadmium chloride in 100ml of deionized water, add 0.192g of glutathione, adjust the pH of the solution to 8.0 with 1M sodium hydroxide solution, and pass nitrogen gas for 30 minutes to obtain a cationic precursor;

[0034] 3. Under stirring, inject 400 μl of the anion precursor solution prepared in step 1 into the cation precursor solution prepared in step 2, heat to 90° C. for reflux reaction for 9 hours, stop heating, and cool to room temperature to obtain a cadmium telluride quantum dot solution.

[0035] 4. Dissolve 5g of sodium carbonate in 100ml of cadmium telluride quantum dot solution prepared in step 3, quickly add 150ml of ethanol under stirring to form a precipitate, filter, dry, and grind into fine powder to obtain cadmium telluride quantum do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com