Quick preparing method for large-area surface Raman spectrum enhancing monocrystalline silicon substrate

A surface-enhanced Raman and single crystal silicon technology, applied in Raman scattering, ion implantation plating, coating, etc., can solve the problems of low preparation efficiency, preparation cost and high environmental requirements, and achieve high structural reproducibility, The effect of short preparation cycle and high controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

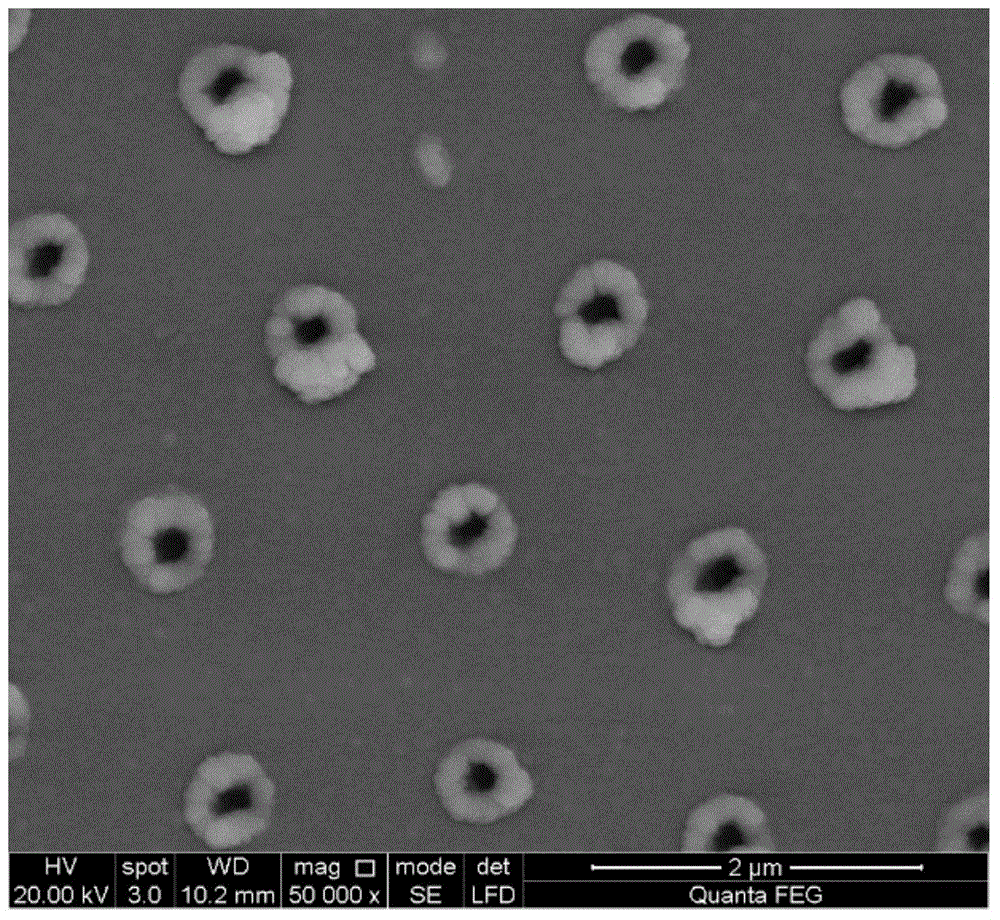

[0028] A single layer of SiO with hexagonal close-packed distribution was arranged on the surface of the cleaned single crystal silicon wafer sample by direct drop coating method 2 Microspheres, the size of the microspheres used is 1.5 μm; place the monocrystalline silicon sample on the target platform, adjust the optical path, and use an ultra-short pulse (10ps) laser with an ultraviolet wavelength to perform a positive defocus single line scan, and the scanning interval is the laser spot Size, repetition rate is 400kHz, scanning speed is 1200mm / s, power density is 5W / mm 2 ; Immerse the cleaned monocrystalline silicon sample in an aqueous sodium hydroxide solution containing ethanol, corrode it for 10 seconds in an environment with a water bath temperature of 75 ° C, take it out and rinse it with deionized water, and obtain a monocrystalline silicon wafer with a microstructure array, In the described aqueous solution, the mass percentage of sodium hydroxide is 10%, and the ma...

Embodiment 2

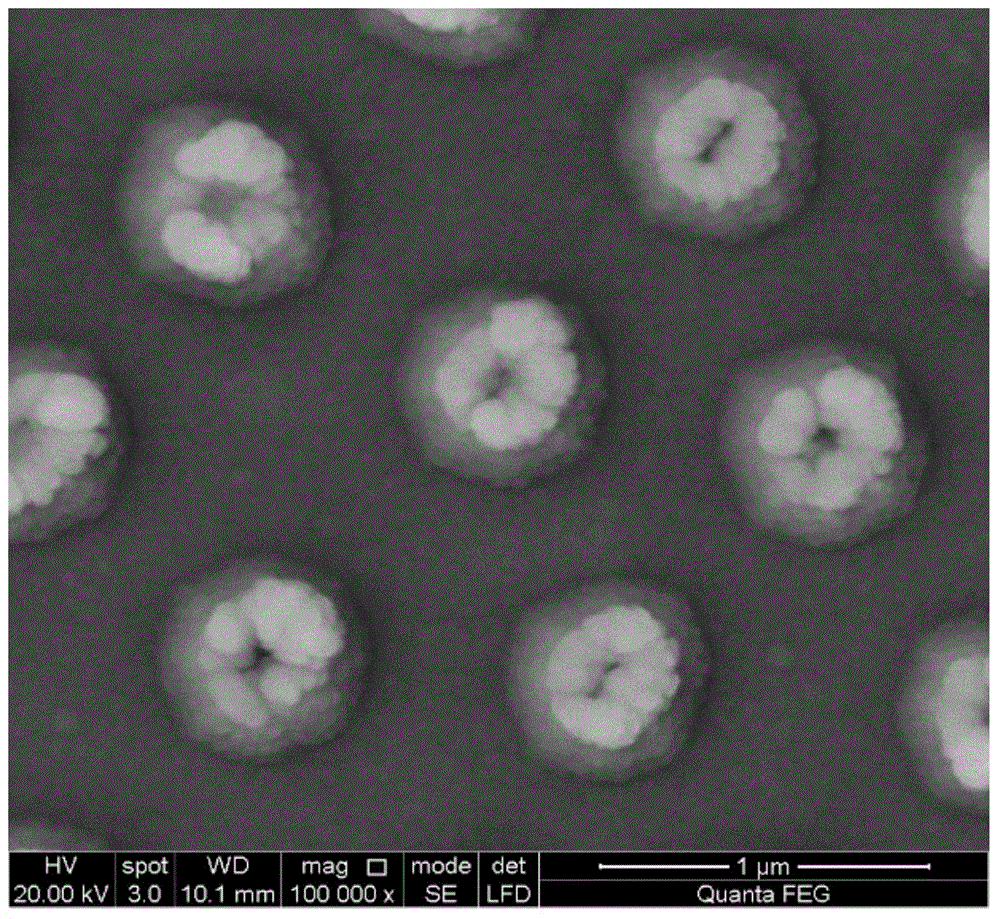

[0031] A single layer of SiO with hexagonal close-packed distribution was arranged on the surface of the cleaned single crystal silicon wafer sample by direct drop coating method 2 Microspheres, the size of the microspheres used is 1 μm; the single crystal silicon sample is placed on the target platform, the optical path is adjusted, and the ultrashort pulse (10ps) laser of ultraviolet wavelength is used for positive defocus single line scanning, and the scanning interval is the size of the laser spot , the repetition frequency is 200kHz, the scanning speed is 1000mm / s, and the power density is 20W / mm 2 ; Immerse the cleaned monocrystalline silicon sample in an aqueous sodium hydroxide solution containing ethanol, corrode it for 30 seconds in an environment with a water bath temperature of 75° C., take it out and rinse it with deionized water, and obtain a monocrystalline silicon wafer with a microstructure array, In the described aqueous solution, the mass percentage of sodiu...

Embodiment 3

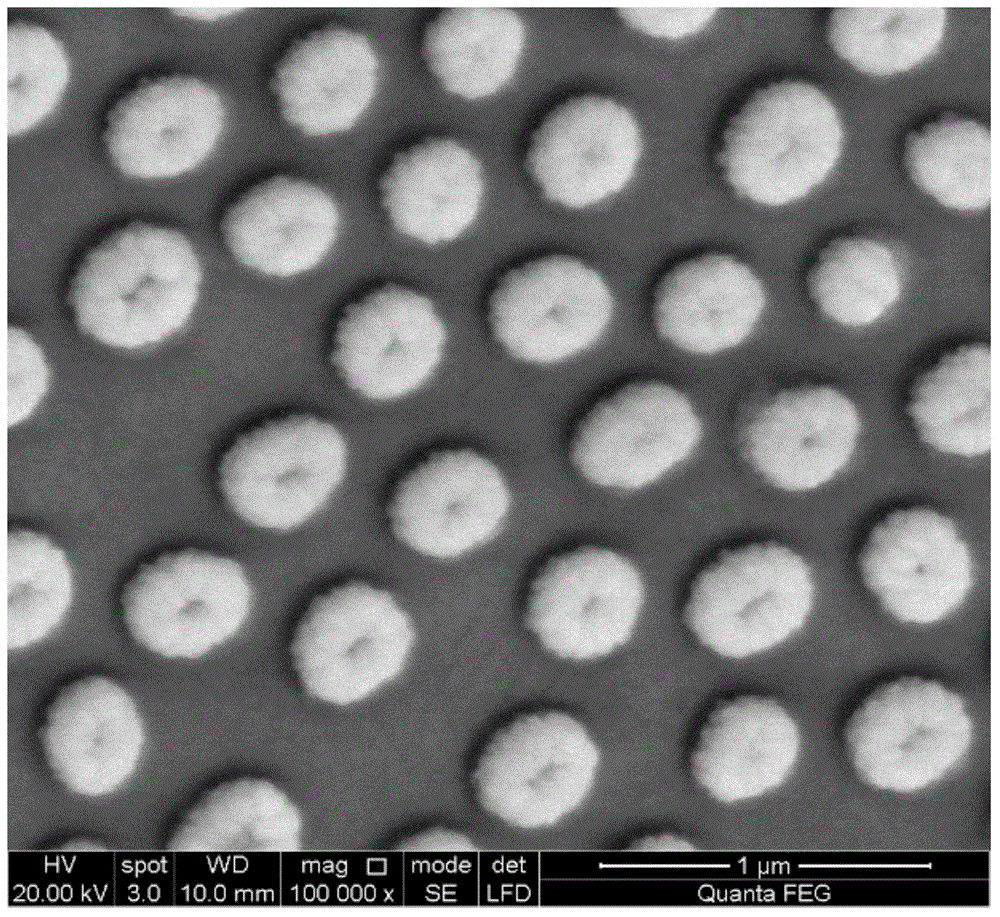

[0034] A single layer of SiO with hexagonal close-packed distribution was arranged on the surface of the cleaned single crystal silicon wafer sample by direct drop coating method 2 Microspheres, the size of the microspheres used is 0.5 μm; place the monocrystalline silicon sample on the target platform, adjust the optical path, and use an ultra-short pulse (10ps) laser with an ultraviolet wavelength to perform a single positive defocus line scan, and the scanning interval is the laser spot Size, repetition rate 200kHz, scanning speed 1200mm / s, power density 25W / mm 2 Immerse the cleaned monocrystalline silicon sample in an aqueous sodium hydroxide solution containing ethanol, corrode it for 30 seconds in an environment with a water bath temperature of 70° C., take it out and rinse it with deionized water, and obtain a monocrystalline silicon wafer with a microstructure array, In the described aqueous solution, the mass percentage of sodium hydroxide is 10%, and the mass percent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com