A Harmless Treatment Process and System for Drilling Solid Waste

A harmless treatment and drilling technology, applied in sludge treatment, pyrolysis treatment sludge, solid waste removal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

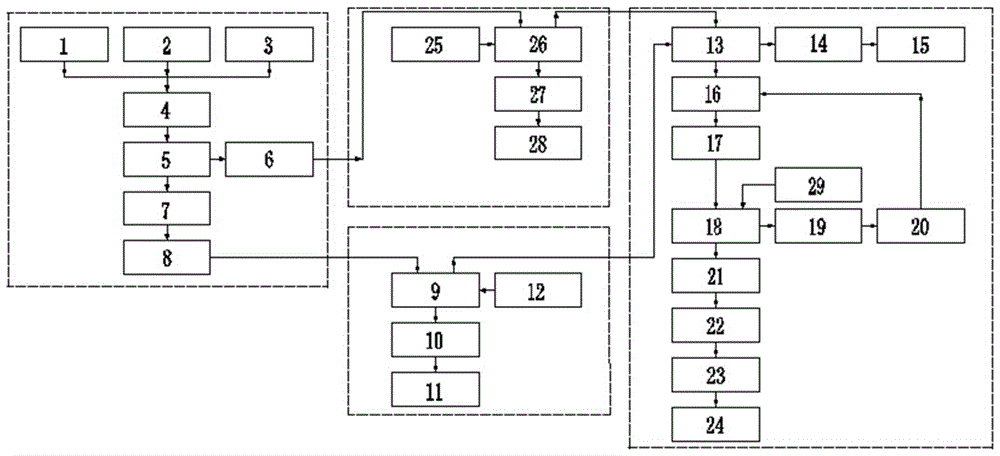

[0064] This embodiment provides a harmless treatment process for drilling solid waste, such as figure 1 shown, including the following steps:

[0065] (a) Screening and separation of sludge particles: the debris sludge produced by the vibrating screen 1, the desilter 2 and the centrifuge 3 is transported to the solid-liquid screening mechanism 5 through the sludge auger conveying device 4 for a long distance. Solid-liquid sieving to obtain rock debris solid waste coarse particles with a particle size greater than 40 mesh and sludge slurry with a particle size less than 40 mesh, and transport the rock debris solid waste coarse particles to the rock debris solid waste bin 6 for processing, and the sludge The mud is transported through the mud tank 7 to the pressure-supply slurry delivery mechanism 8 for processing;

[0066] Wherein, after the sludge slurry is stored in the slurry tank 7, the sludge slurry in the slurry tank 7 is stirred by using a mechanical agitator and an air...

Embodiment 2

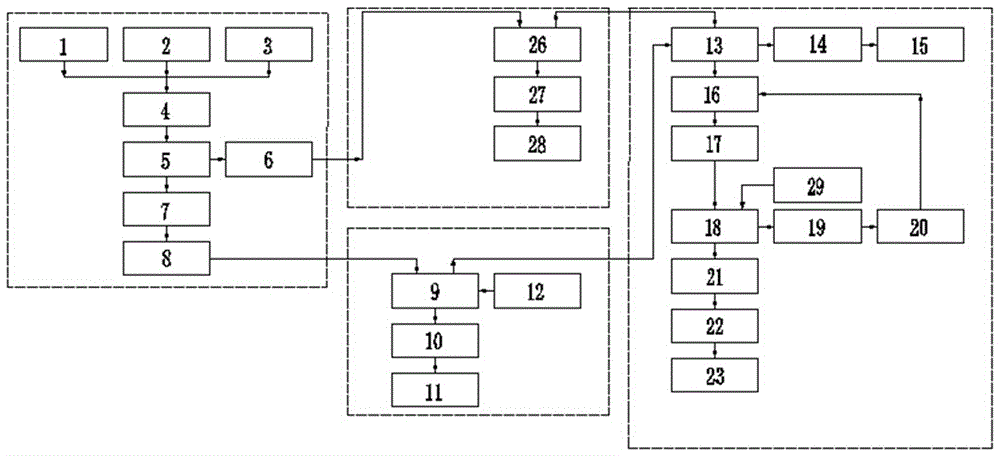

[0074] This embodiment provides a treatment system for the harmless treatment process of drilling solid waste in the first embodiment, such as figure 2 As shown, including sludge non-falling slurry supply assembly, cuttings particle high temperature pyrolysis assembly, mud high temperature pyrolysis assembly and toxic and harmful gas treatment assembly;

[0075] The sludge non-falling slurry supply assembly includes the above-mentioned vibrating screen 1, sand and desilter 2, centrifuge 3, sludge auger conveying device 4, solid-liquid screening mechanism 5, cuttings and solid waste bin 6 and pressure The slurry feeding conveying mechanism 8, and the outlet of the sludge auger conveying device 4 communicates with the inlet of the solid-liquid screening mechanism 5, and the inlet of the cuttings solid waste bin 6 communicates with the inlet of the solid-liquid screening The first discharge port of the mechanism 5 is connected, and a mud tank 7 is arranged between the feed port ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com