Optical waveguide sensing chip, preparation method thereof, and use

A sensor chip and optical waveguide technology, applied in scanning probe technology, instruments, etc., can solve the problems of poor acid-base stability, difficult synthesis, and complicated preparation process of alumina

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

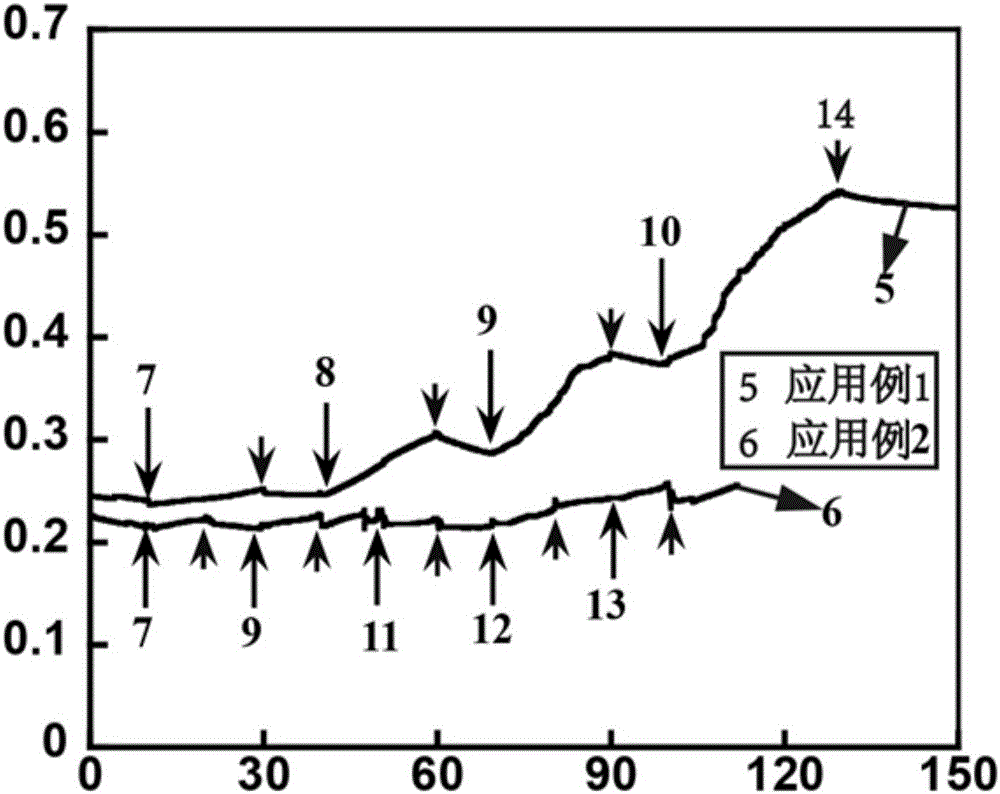

Examples

preparation example Construction

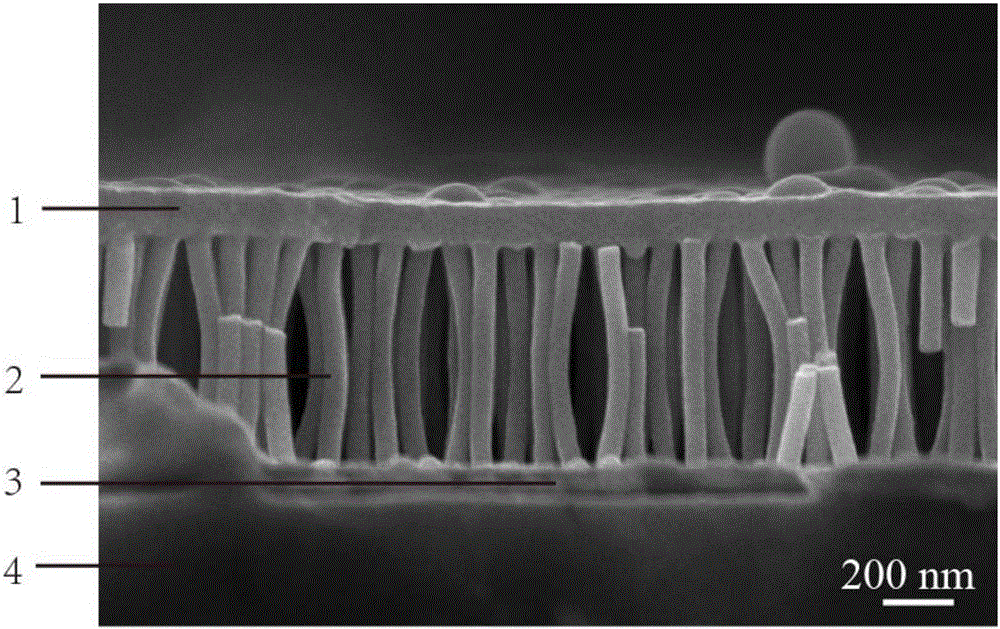

[0031] In some embodiments, a method for preparing an optical waveguide sensor chip based on a nanopillar array structure, the method includes the following steps:

[0032] (1) the gold film substrate is immersed in the organic solution of mercaptosilane to process;

[0033] (2) process the gold film substrate after processing in step (1) with acid solution;

[0034] (3) the porous anodic aluminum oxide film is pasted on the gold film surface after step (2) processing;

[0035] (4) the permeable porous aluminum oxide film pasted on the surface of the gold film obtained through step (3) is immersed in solution for a period of time;

[0036] (5) stirring the sample obtained through step (4) with an acidic organic solution;

[0037] (6) Treat the sample treated in step (5) with an acid solution.

[0038] According to an embodiment of the present invention, in step (1), the gold film is a gold layer with a thickness of 40-50nm, preferably 40-45nm, coated on the surface of the...

Embodiment 1

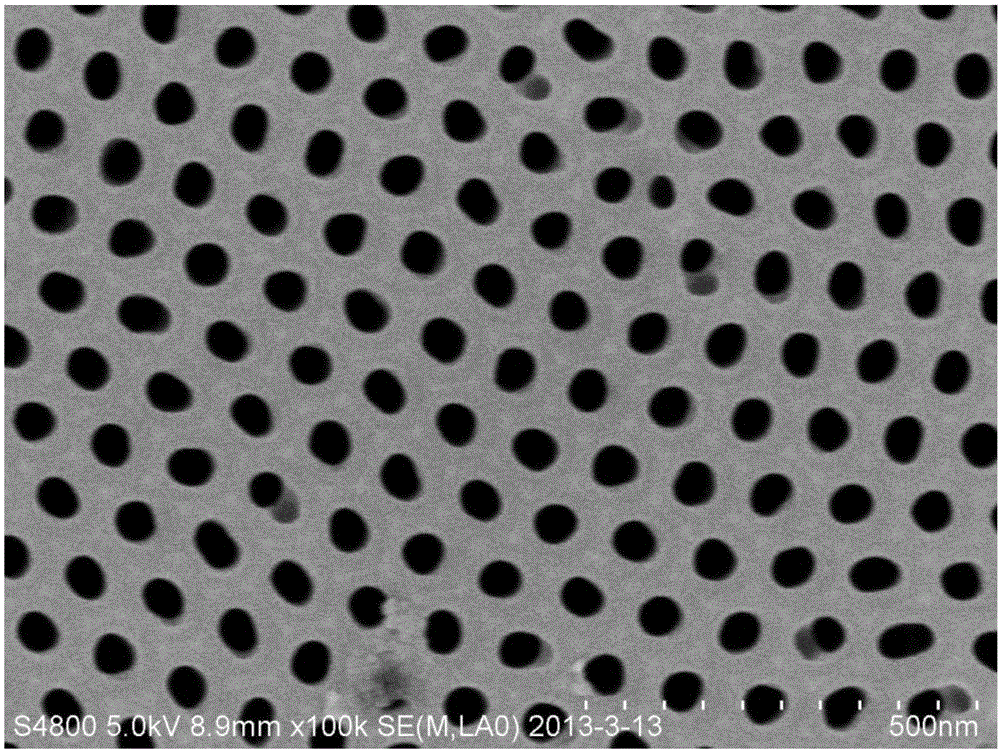

[0051] This specific example is used to illustrate the preparation of an optical waveguide sensor chip of a mesoporous silica nano-column array film by using the method of the embodiment of the present invention.

[0052] (1) Preparation of gold film: immerse the K9 glass sheet in H with a volume ratio of 1:2 2 o 2 (mass fraction is 30%) and H 2 SO 4 (mass fraction is 98%) in the mixed solution, stand for 2 hours, then rinse with a large amount of deionized water, blow dry with nitrogen. The cleaned K9 glass sheet was sputtered with a layer of 2nm thick chromium as an adhesion layer by magnetron sputtering method, and then a layer of 40nm thick gold was sputtered, which is the gold substrate used in this embodiment.

[0053] (2) Ethanol solution treatment of gold film substrate with mercaptosilane: prepare 20 mmol / L (3-mercaptopropyl)trimethoxysilane solution with ethanol. Immerse the gold film substrate obtained in step (1) in the above solution for 8 hours.

[0054] (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com