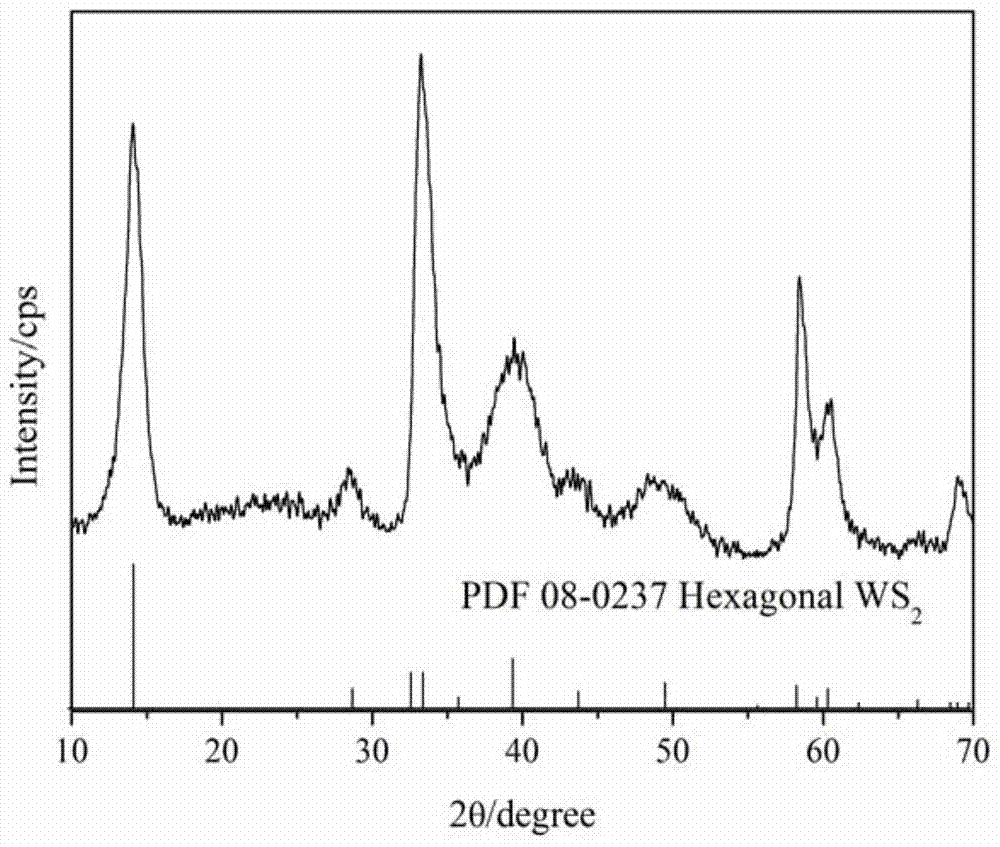

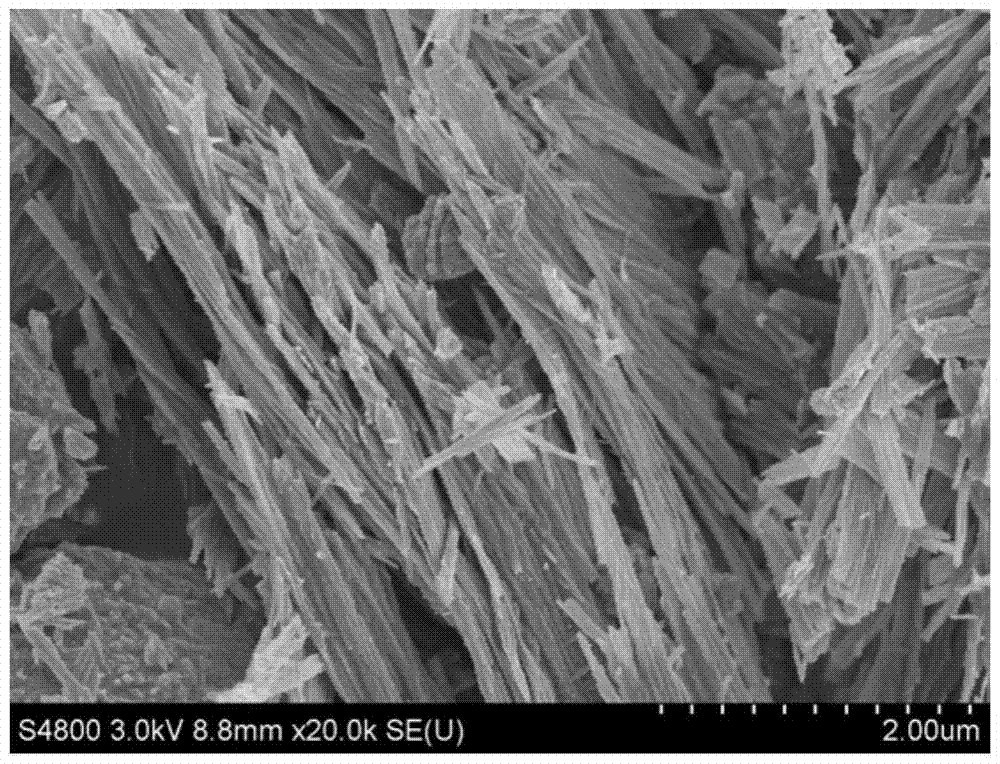

a fibrous ws 2 Preparation method of nano negative electrode material

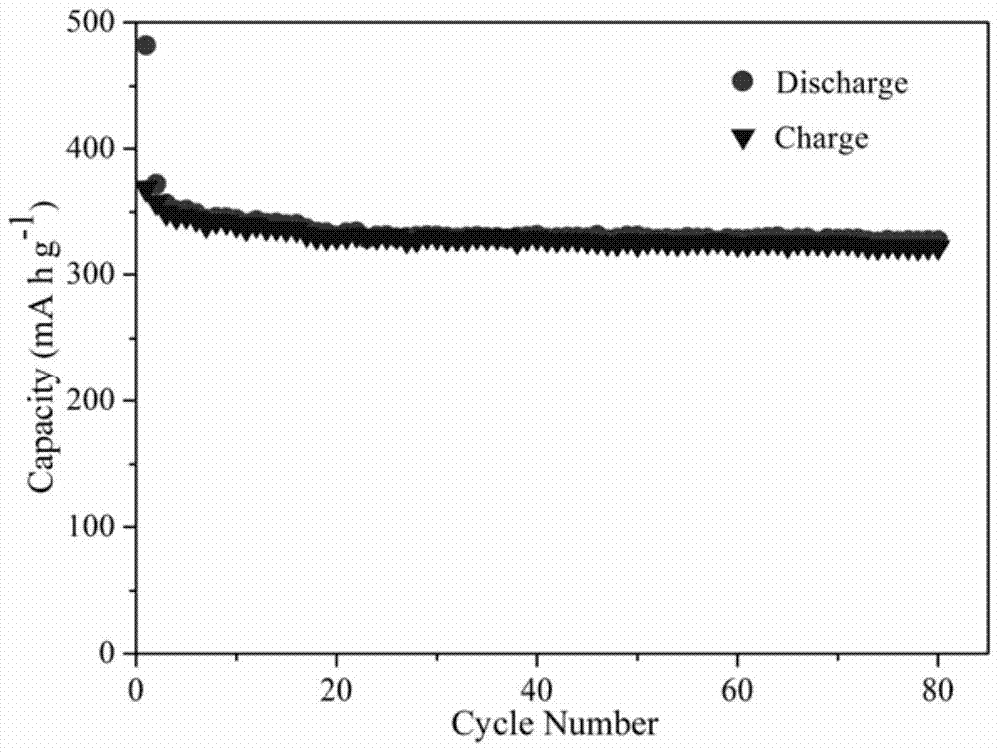

A negative electrode material, fiber-shaped technology, applied in the field of preparation of fibrous WS2 nano-negative electrode materials, can solve the problems of difficult control of reactant ratio, easy powder agglomeration, high equipment requirements, etc., achieve light agglomeration, avoid agglomeration, charge and discharge The effect of high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Step 1: Analytical pure sodium tungstate dihydrate (Na 2 WO 4 2H 2 O) dissolved in deionized water, control W 6+ The concentration is 0.005mol / L, and keep stirring until the sodium tungstate dihydrate dissolves, then add citric acid, and control the ratio of the added citric acid to tungsten to n W : n 柠檬酸 = 3: 2, then placed in a 300W ultrasonic cleaner and ultrasonically oscillated for 50 minutes to obtain solution A;

[0025] Step 2: Add the mixture of analytically pure polyethylene glycol 4000 (PEG 4000) and disodium edetate (EDTA) in solution A PEG4000 :m EDTA =5:1), the total amount of control is wt% (wt% PEG4000 +wt% EDTA ) = 10%, and constantly stirred to fully dissolve polyethylene glycol 4000 and disodium edetate, and then put it into a 300W ultrasonic cleaner for ultrasonic oscillation for 50 minutes, and the obtained solution was recorded as solution B;

[0026] Step 3: After reacting and aging solution B in an electric heating constant temperature w...

Embodiment 2

[0032] Step 1: Analytical pure sodium tungstate dihydrate (Na 2 WO 4 2H 2 O) dissolved in deionized water, control W 6+ The concentration of 0.4mol / L, and keep stirring until sodium tungstate dihydrate dissolves, then add citric acid, control the ratio of the added citric acid to tungsten to n W : n 柠檬酸 = 1:9, then placed in a 700W ultrasonic cleaner for 20 minutes of ultrasonic oscillation to obtain solution A;

[0033] Step 2: Add the mixture of analytically pure polyethylene glycol 4000 (PEG 4000) and disodium edetate (EDTA) in solution A PEG4000 :m EDTA =1:4), the total amount of control is wt% (wt% PEG4000 +wt% EDTA ) = 40%, and constantly stirring to fully dissolve polyethylene glycol 4000 and disodium edetate, then put it into a 700W ultrasonic cleaner and ultrasonically vibrate for 10 minutes, and the obtained solution is recorded as solution B;

[0034] Step 3: React and age solution B in an electric heating constant temperature water bath at 90°C for 1 hour, ...

Embodiment 3

[0038] Step 1: Analytical pure sodium tungstate dihydrate (Na 2 WO 4 2H 2 O) dissolved in deionized water, control W 6+ The concentration is 0.2mol / L, and keep stirring until sodium tungstate dihydrate dissolves, then add citric acid, and control the ratio of the added citric acid to tungsten to n W : n 柠檬酸 = 3:7, then placed in a 500W ultrasonic cleaner and ultrasonically oscillated for 30 minutes to obtain solution A;

[0039] Step 2: Add the mixture of analytically pure polyethylene glycol 4000 (PEG 4000) and disodium edetate (EDTA) in solution A PEG4000 :m EDTA =1:1), the total amount of control is wt% (wt% PEG4000 +wt% EDTA ) = 30%, and constantly stirred to fully dissolve polyethylene glycol 4000 and disodium edetate, then put it into a 500W ultrasonic cleaner and vibrate ultrasonically for 30min, and the obtained solution was recorded as solution B;

[0040] Step 3: After reacting and aging solution B in an electric heating constant temperature water bath at 70°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com